61

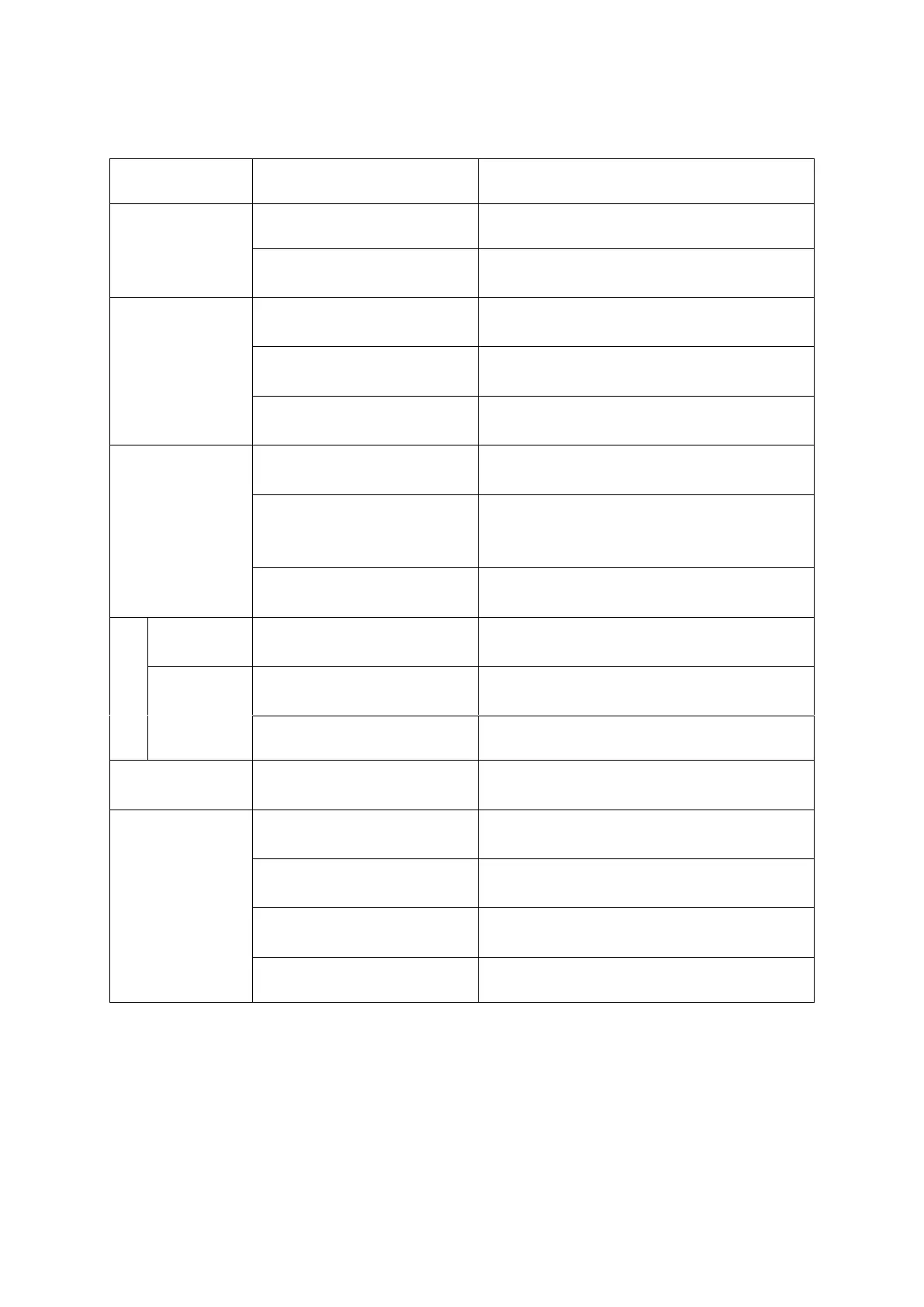

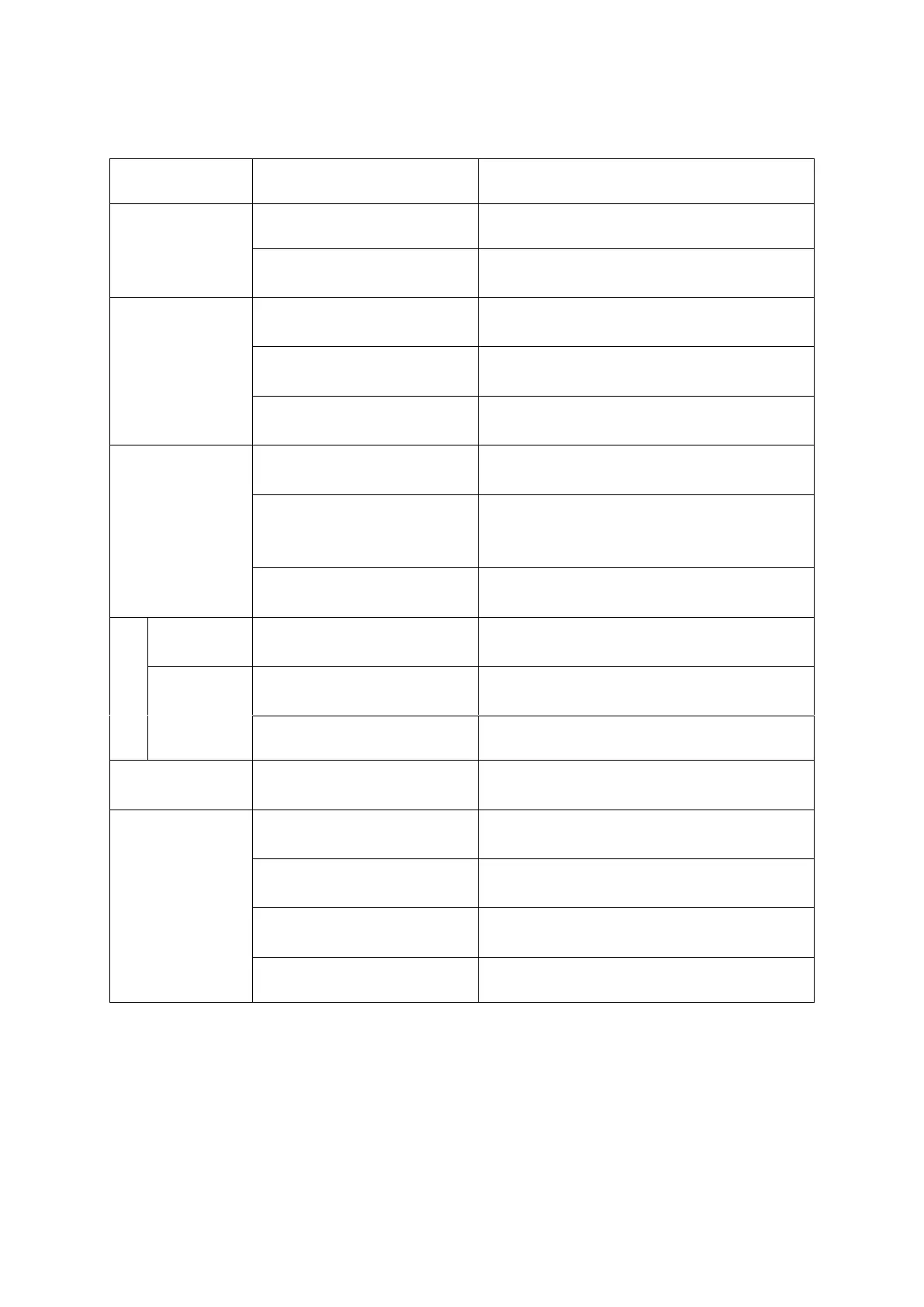

2.2 Hydraulic system fault diagnosis and correction

No oil pumps

from the pump

Fill to the specified oil level

Clean oil pipe and oil tank. If hydraulic oil is

dirty, please change it.

Low oil pressure

of oil pump output

Bearing worn; retainer,

O-ring damage

Change the bad spare parts

Adjustment failure of safety

valve

Rise pressure with pressure gage

Fill hydraulic oil to the oil tank, use the pump

after bubble vanishing

Cavitation arising from the

strainer blocking

Adjust or replace soft tube and clean the

strainer

Cavity caused by the high

viscosity of hydraulic oil

Replace new hydraulic oil, whose viscosity

suits pump running speed. Work only when

the oil temperature is normal

Bubble in the hydraulic oil

Check the reason for the bubble and then

take measures

Lifting inching switch loosen

or damage

Solenoid valve block or

damage

Pressure of

safety valve is

unstable or can’t

be adjusted

Pressure adjusting screw

loosen

Pressure adjusting spring

deformation or damage.

Safety valve spool wear or

sticking

Replace or clean to reassemble.

Loading...

Loading...