RevV4 Valves & Systems Service Manual

47

Hankscraft Runxin, LLC 300 Wengel Drive 608.524.9465 hrh2o.com sales@hrh2o.com

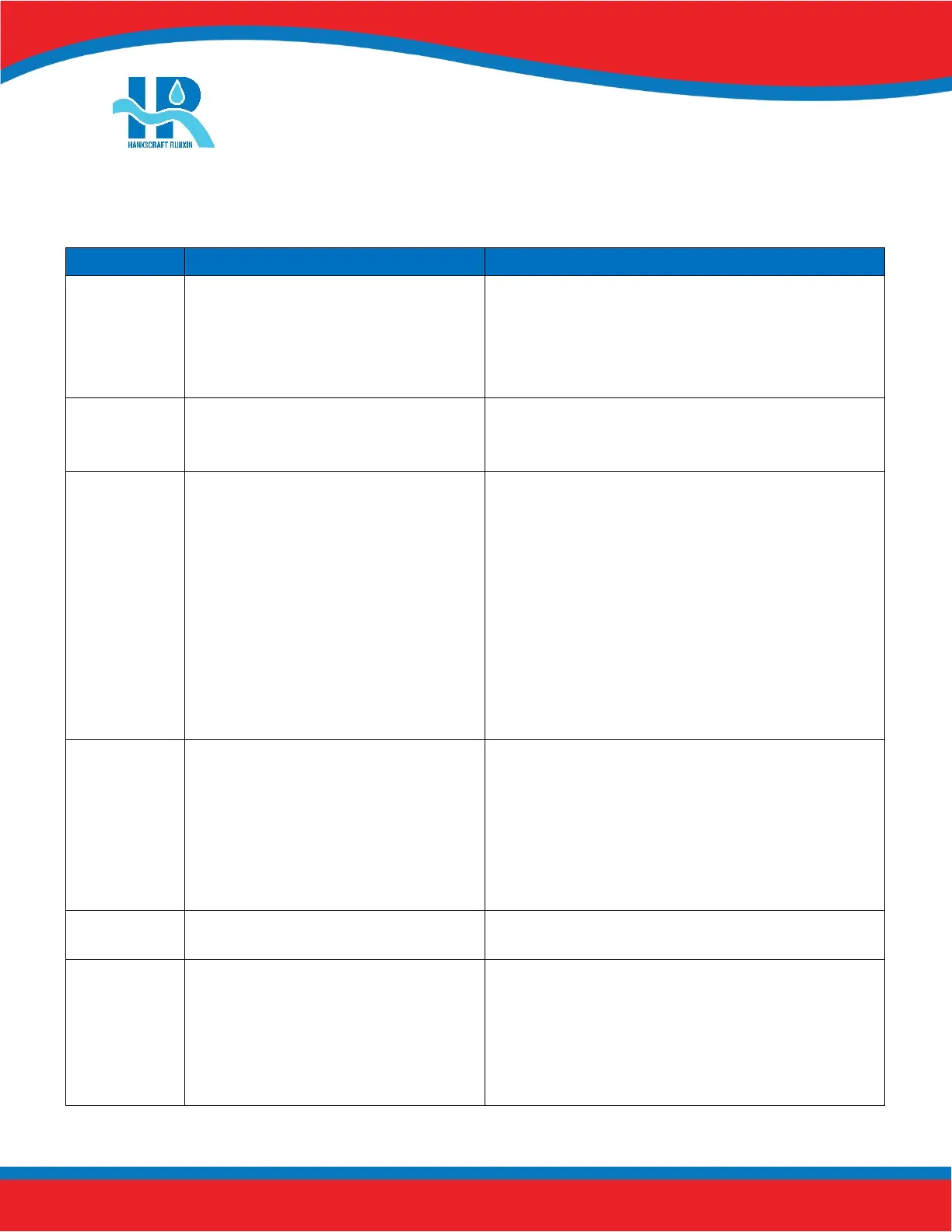

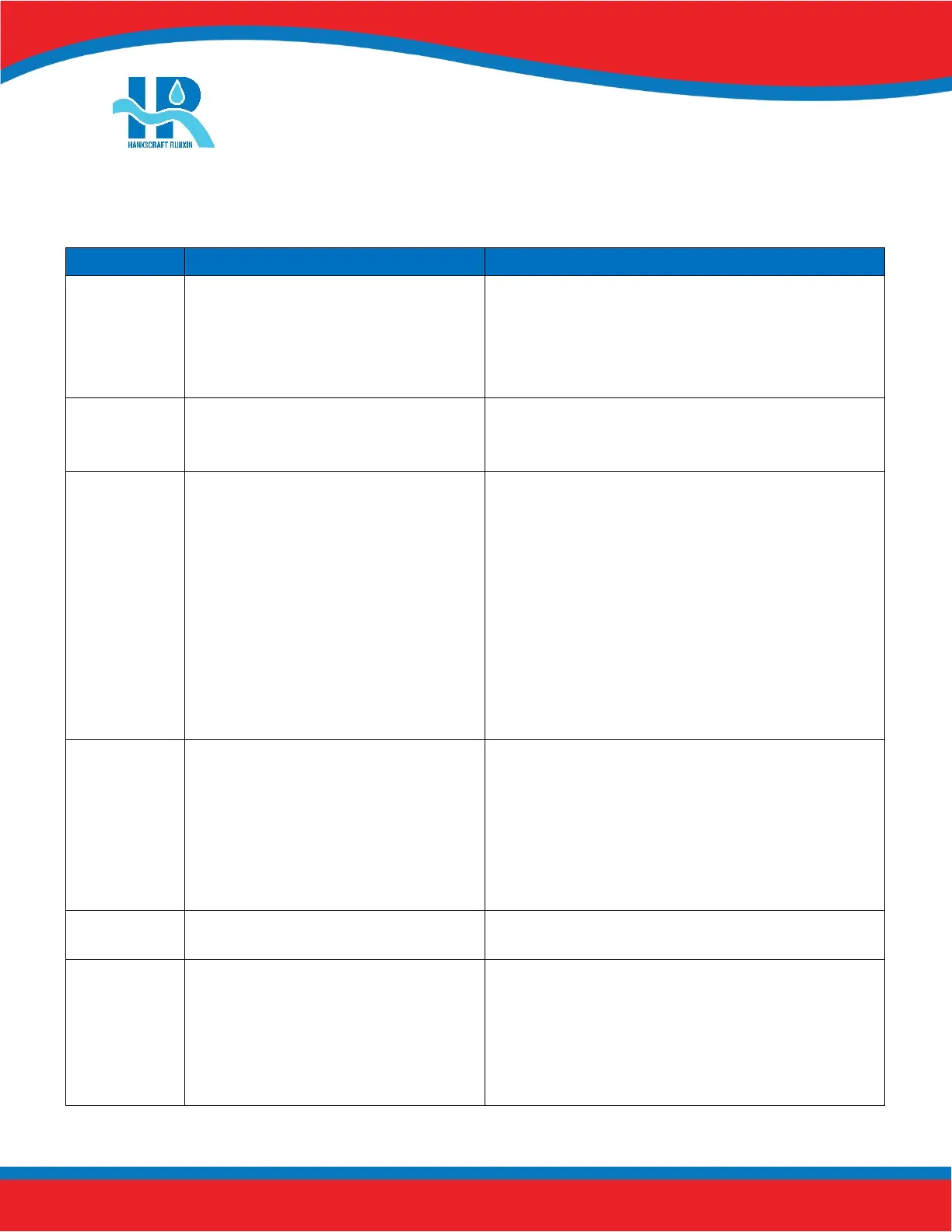

11. Troubleshooting

Control Valve

Problem Cause Correction

1. Softener fails

to regenerate

A. Electrical service to unit has been

interrupted.

B. Regeneration cycles set incorrectly.

C. Controller is defective.

D. Motor failure.

A. Check for consistent electrical service.

B. Reset regeneration cycles.

C. Replace controller.

D. Replace motor.

2. Regeneration

time is not

correct

A. Time of Day not set correctly.

B. Power failure over 3 days.

Check program and reset time of day.

3. Hard water

A. Bypass valve is open or leaking.

B. No salt in brine tank.

C. Injector plugged.

D. Insufficient water level in brine tank.

E. Leak at O-ring on riser pipe.

F. Internal valve leak.

G. Regeneration cycles not correct.

H. Shortage of resin.

I. Bad quality of feed water or meter blocked.

A. Close or repair bypass valve.

B. Add salt to brine tank and maintain salt level above water

level.

C. Change or clean injector.

D. Check brine tank refill time.

E. Make sure riser pipe is not cracked. Check O-ring and tube

pilot.

F. Change valve body.

G. Set correct regeneration cycles in the program.

H. Add resin to mineral tank and check for leaks.

I. Reduce the inlet turbidity, clean or replace meter.

4. Softener fails

to draw brine

A. Line pressure is too low.

B. Brine line is plugged.

C. Brine line is leaking.

D. Injector is plugged.

E. Internal leakage.

F. Drain line is plugged.

G. Wrong size BLFC, DLFC and injector.

A. Increase line pressure.

B. Clean brine line.

C. Replace brine line.

D. Clean or replace injector.

E. Replace valve body.

F. Clean drain line flow control.

G. Install properly sized BLFC, DLFC and injector. See Page 13.

5. Unit uses too

much salt

A. Improper salt setting. (Brine refill time)

B. Excessive water in brine tank.

A. Check salt usage and salt setting. (Brine refill time)

B. See problem no.6.

6. Excessive

water in brine

tank

A. Brine refill time is too long.

B. Foreign material in brine line.

C. Foreign material in brine valve or plugged

drain line flow control.

D. Power outage during brine fill.

E. Safety valve in brine tank malfunction.

A. Reset correct refilling time.

B. Clean brine line.

C. Clean brine valve, and DLFC.

D. Put the valve in bypass. Install a safety float in brine tank.

E. Repair or replace brine safety valve.

Loading...

Loading...