10

If the cuvet is not indexed, put the cuvet with the factory mark aligned with the sign on the

instrument top.

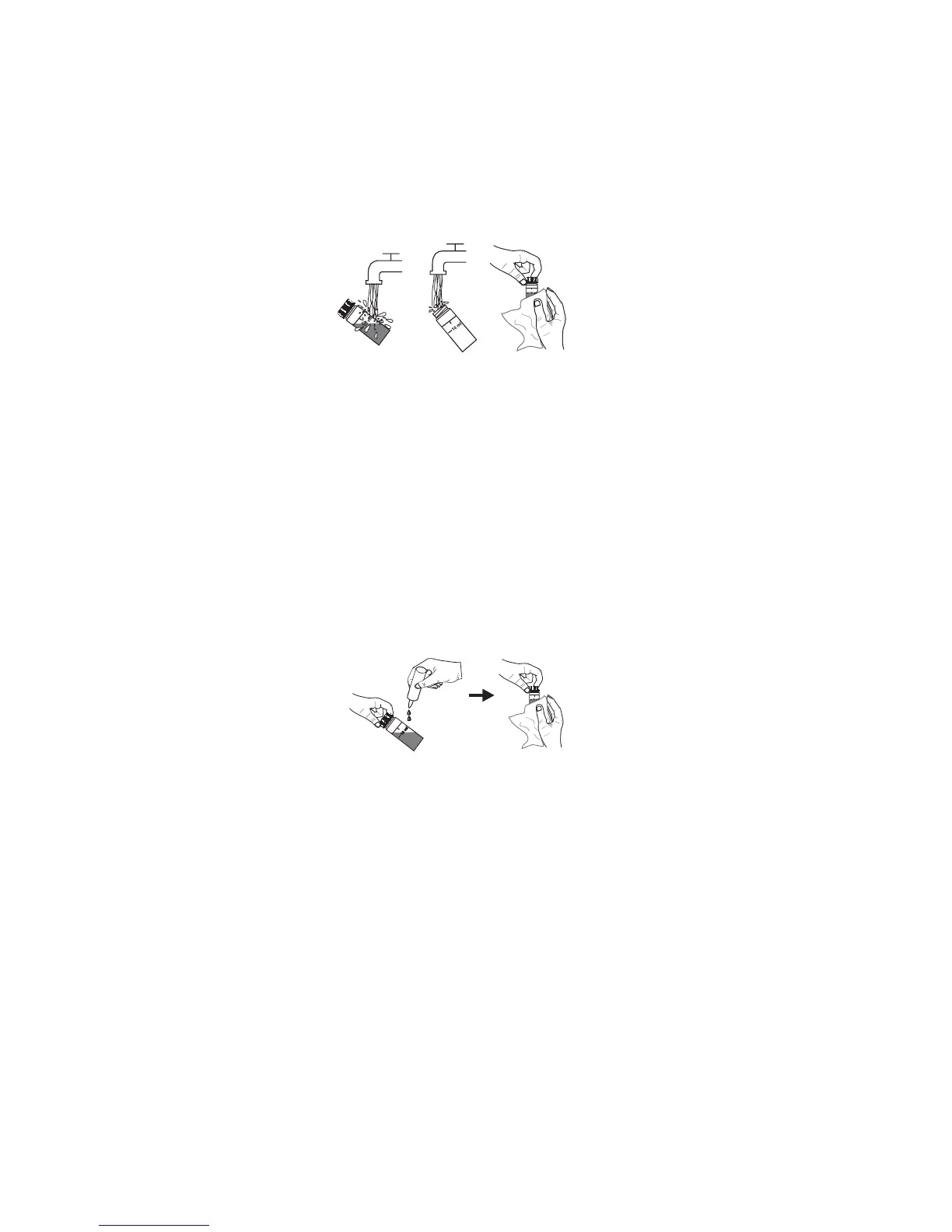

CUVET OILING

To hide minor imperfections and scratches, the cuvets should be oiled outside with the supplied silicone oil.

This is very important, especially for low turbidity samples (< 1 NTU), otherwise scratches can contribute

and alter turbidity readings.

The silicone oil has the same refractive index as the glass and will not alter the turbidity readings. It is

important to apply only a thin layer of silicone oil.

Warning: Do not apply silicone oil in excess because it may retain dirt or contaminate the cuvet

holder of the instrument, altering the turbidity readings.

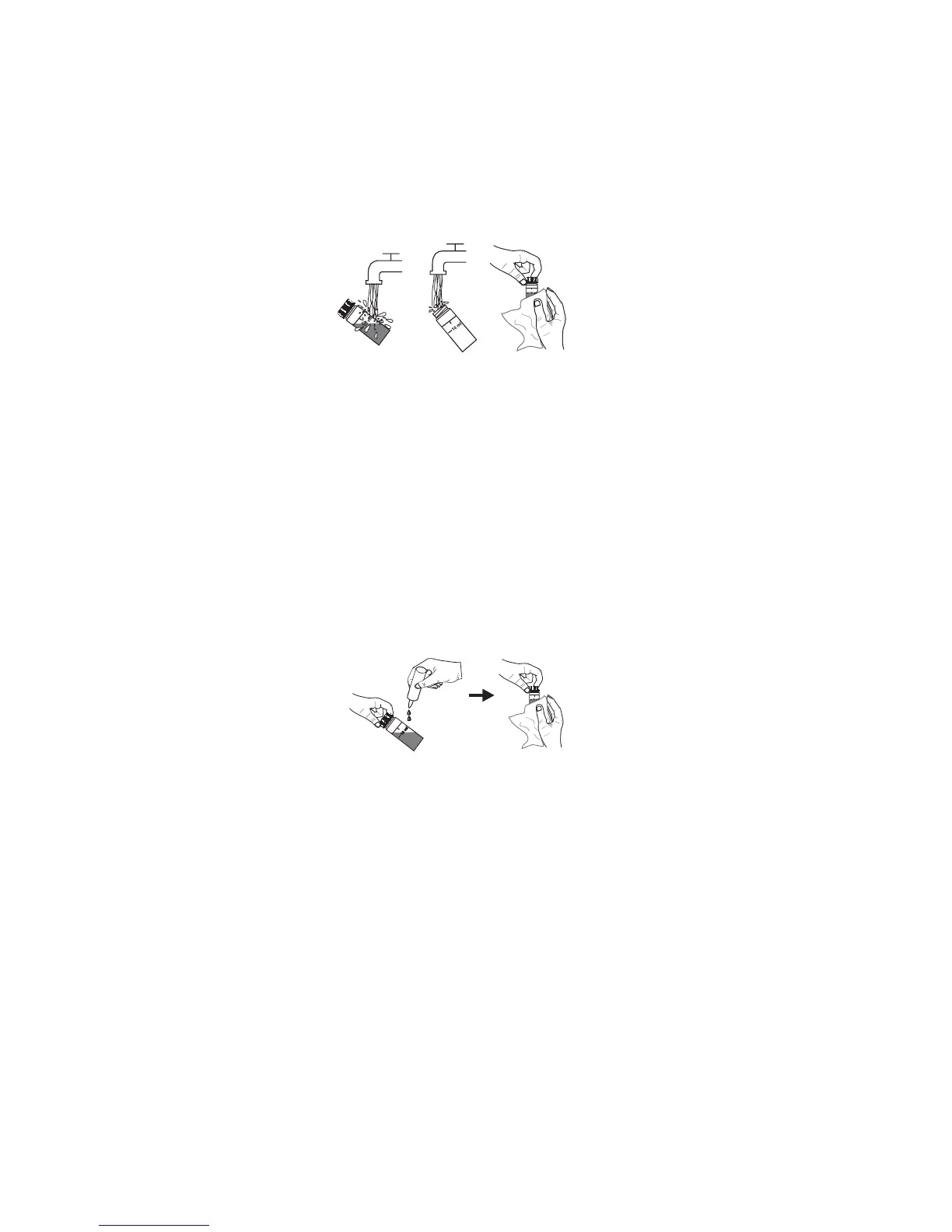

It is very important to apply the silicone oil on a clean, dry cuvet. Apply a few drops of oil and wipe

the cuvet thoroughly with a lint-free cloth. Wipe off the excess oil till you obtain a thin, uniform

layer. If the procedure is correctly followed, the cuvet should appear nearly dry with no visible oil.

Note: The supplied cloth for oiling should be stored together with the silicone oil bottle and cuvets,

taking care to avoid contamination with dirt. After a few oiling procedures, the cloth will

contain enough oil to wipe the bottle with it without adding more oil. From time to time add

some drops of oil on the cuvet to provide the necessary oil quantity in the cloth.

INDEXING A CUVET

It is very important for low turbidity readings to always insert the cuvet into the instrument in the

same position.

All cuvets are factory indexed. This index can be used to put the cuvet with the factory mark on the

cuvet aligned with the sign on the instrument top.

To further reduce the effect of glass imperfections, the cuvet can be indexed and use this new index

as the position mark.

Loading...

Loading...