25©HBS Bolzenschweiss-Systeme GmbH & Co. KG

All rights reserved – Reprinting, in whole or in part, only with the approval of the manufacturer

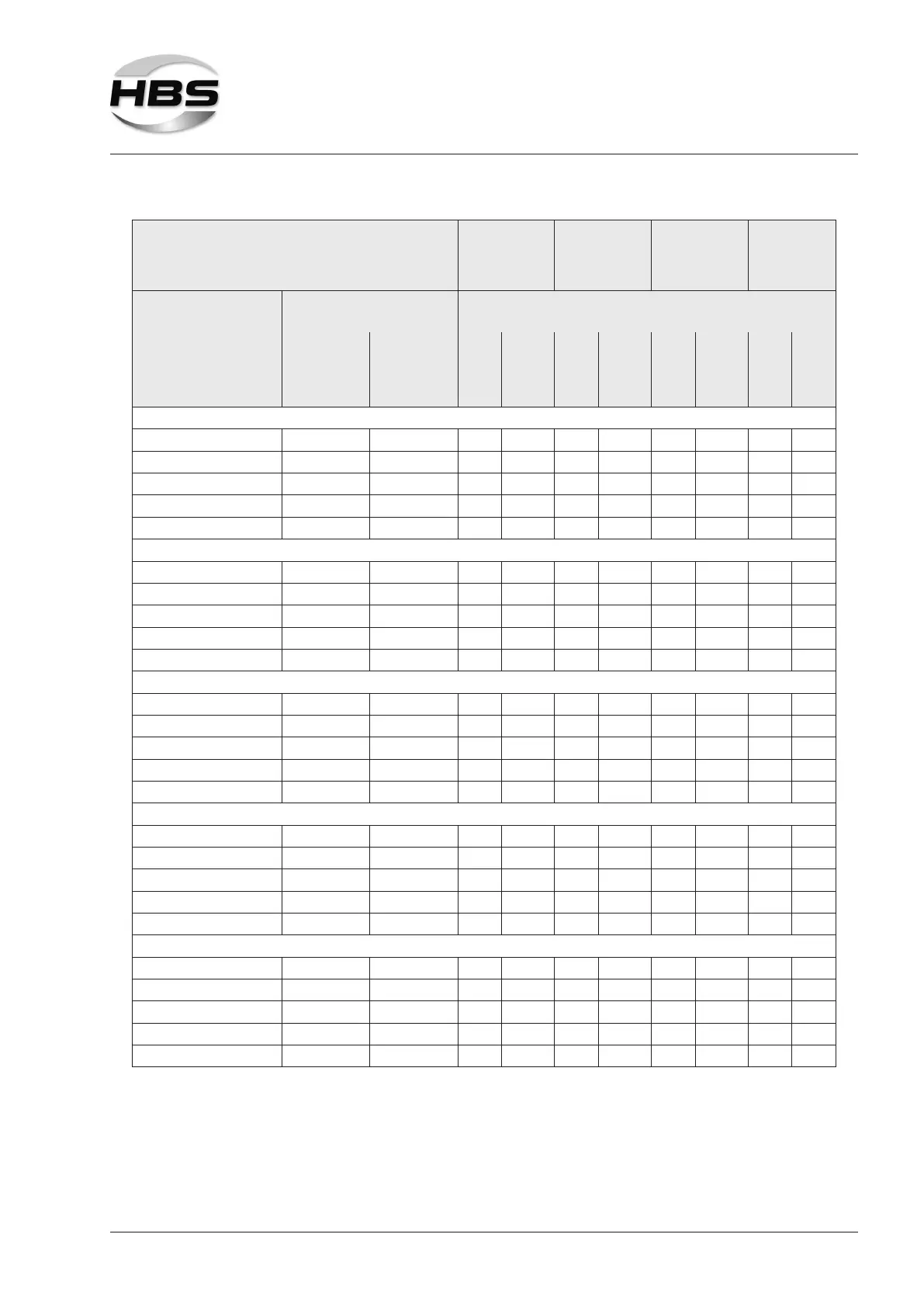

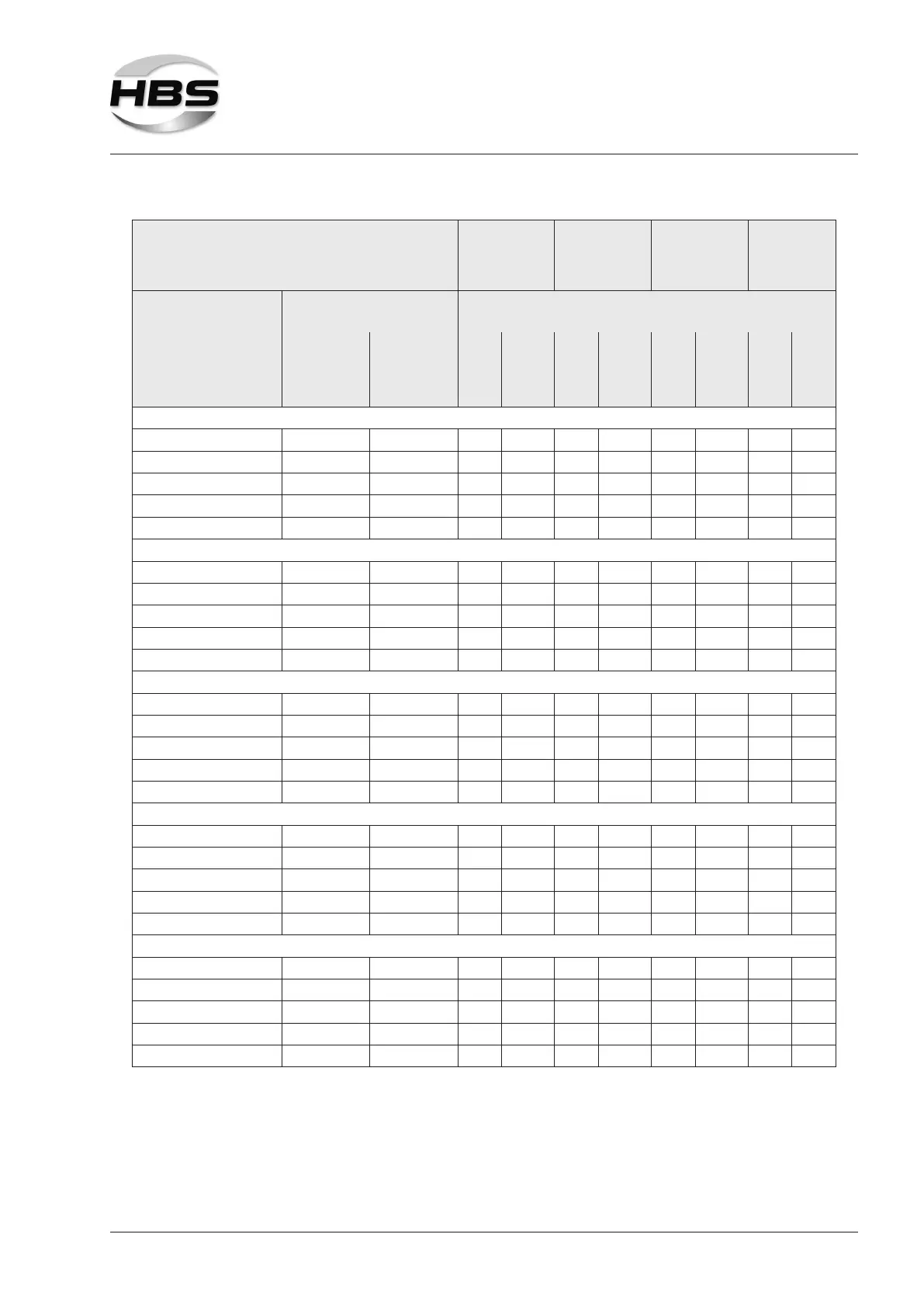

10 Preparing the Welding Gun

Stud welding units CDi 1502 CDi 2302

CDi 3102

CDMi 2402

CDMi 3202

SC Mode

without

shielding gas

Material of

welding elements

Diameter of welding elements

imperial (US)

Welding gun parameters

1)

CA 08

PT, UT IT

Spring force

(scaling)

Lift (mm)

Spring force

(scaling)

Lift (mm)

Spring force

(scaling)

Lift (mm)

Spring force

(scaling)

Lift (mm)

Material of workpiece: Mild steel (suitable for welding)

4.8 (suitable for welding) 1/8“ #6-32 2 1 2 1 2 1 6 1.2

4.8 (suitable for welding) 5/32“ #8-32 2 1.2 2 1.2 2 1.2 6 1.4

4.8 (suitable for welding) 3/16“ #10-32 2 1.6 2 1.6 2 1.6 6 1.6

4.8 (suitable for welding) 1/4“ 1/4-20 6 1.6 6 1.6 6 1.6 6 2

4.8 (suitable for welding) 5/16“ 5/16-18 -- -- 6 2 6 2 -- --

Material of workpiece: Galvanised steel (suitable for welding)

4.8 (suitable for welding) 1/8“ #6-32 6 1 6 1 6 1 2 1

4.8 (suitable for welding) 5/32“ #8-32 6 1 6 1 6 1 2 1

4.8 (suitable for welding) 3/16“ #10-32 3 1 3 1 6 1 2 1

4.8 (suitable for welding) 1/4“ 1/4-20 3 1 3 1 6 1 2 1.2

4.8 (suitable for welding) 5/16“ 5/16-18 -- -- -- -- -- -- 3 1.2

Material of workpiece: Alloyed steel (suitable for welding)

A2-50 1/8“ #6-32 6 1.4 6 1.4 6 1.4 6 1.2

A2-50 5/32“ #8-32 6 1.4 6 1.4 6 1.4 3 1.2

A2-50 3/16“ #10-32 6 1.6 6 1.6 6 1.6 3 1.6

A2-50 1/4“ 1/4-20 6 2 6 2 6 2 3 2

A2-50 5/16“ 5/16-18 6 2 6 2 6 2 3 2

Material of workpiece: Alloyed steel (suitable for welding)

CuZn37 1/8“ #6-32 6 1 6 1 6 1 3 1

CuZn37 5/32“ #8-32 6 1 6 1 6 1 3 1.2

CuZn37 3/16“ #10-32 -- -- -- -- -- -- 3 1.4

CuZn37 1/4“ 1/4-20 -- -- -- -- --- -- 3 1.6

CuZn37 5/16“ 5/16-18 -- -- -- -- -- -- -- --

Material of workpiece: Aluminium

AlMg3 1/8“ #6-32 6 - 9 1.8 6 - 9 1.8 6 - 9 1.8 -- --

AlMg3 5/32“ #8-32 6 - 9 2 - 3 6 - 9 2 - 3 6 - 9 2 - 3 -- --

AlMg3 3/16“ #10-32 6 - 9 3 - 4 6 - 9 3 - 4 6 - 9 3 - 4 -- --

AlMg3 1/4“ 1/4-20 6 - 9 4 6 - 9 4 6 - 9 4 -- --

AlMg3

2)

5/16“

2)

5/16-18

2)

6 - 9 4 6 - 9 4 6 - 9 4 -- --

1)

to be checked by test weldings

2)

Due to the material characteristics of Aluminium and the corresponding limitations regarding the process stabili-

ty a maximum stud diameter of 6 mm is recommended.

Loading...

Loading...