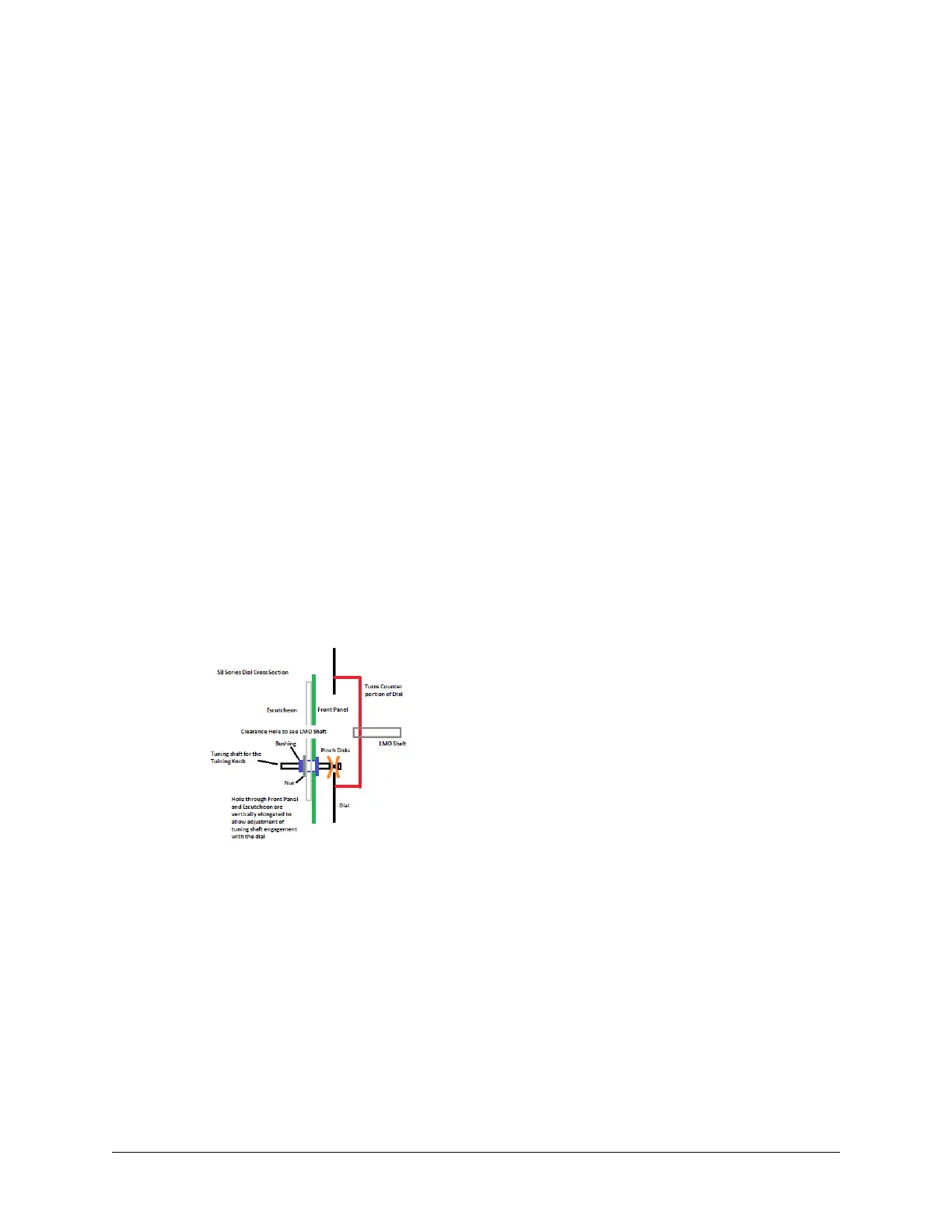

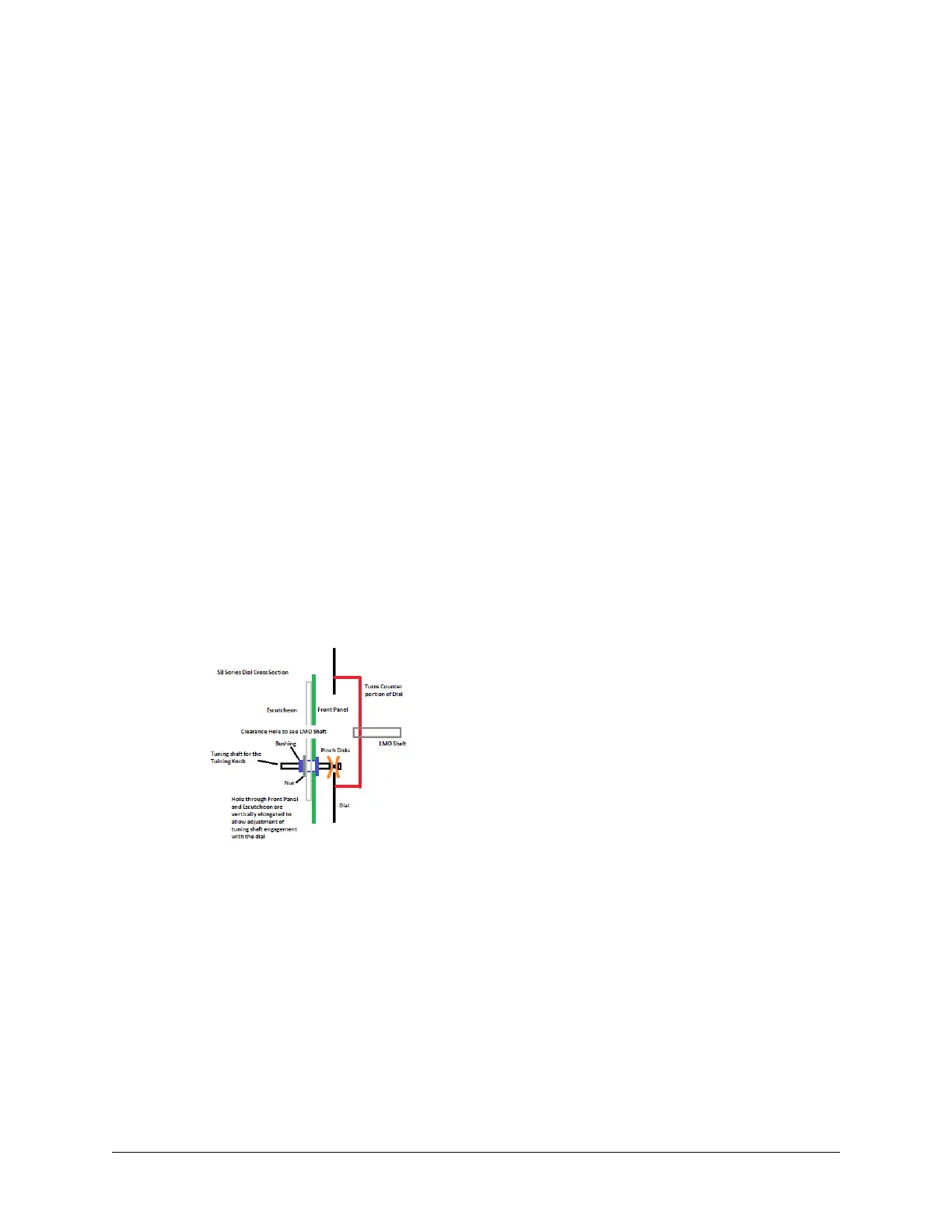

If the dial mechanism slips while tuning, it may be that the beveled pulley is not gripping

the metal ring sufficiently. To remedy this, loosen the nut on the front of the shaft slightly

and move the bushing and shaft down very slightly.

If the pulley on the end of the main tuning shaft is positioned to the front of the metal

ring, the dial will not move unless the main tuning shaft is pushed in slightly. On the

other hand, if the pulley is positioned behind the metal ring, the dial will only move when

the main tuning shaft is pulled forward slightly so that the pulley is pressing on the back

of the metal ring.

In either case, the pulley can be positioned correctly by removing the large knob on the

tuning shaft and loosening the nut enough so that the bushing can be moved up and

down. When this has been done, the bushing can be moved up enough to permit the

main tuning shaft to be moved in and out. While doing this, the pulley can be

repositioned on the metal ring. This has to be done by “feel” as it is not possible to see

when the pulley is correctly positioned. When the pulley is correctly positioned, the main

tuning shaft and bushing can be moved down enough to provide smooth operation of

the dial, the nut tightened and the knob replaced.

Note that it is not necessary to remove either the escutcheon or front panel to perform

this operation.

Figure 10. Main Tuning Shaft Beveled Pulley

Servicing Procedures Page 72

Loading...

Loading...