OPERATION | PAGE 12

7. Fumes control. The CEM7 control unit allows you to handle start-up in fumes

limitation mode by:

• Assigning a programmable output (Settings table, parameter 1 to 4,

value 97) that enables a fumes limitation system during the start-up

process that remains active for a programmable length of time (Times

table, parameter 33) once the engine is running.

• It is possible to programme an idling start-up speed (table J1939,

parameter 8) that remains active for a programmable length of time

(Times table, parameter 33) before commuting to rated speed.

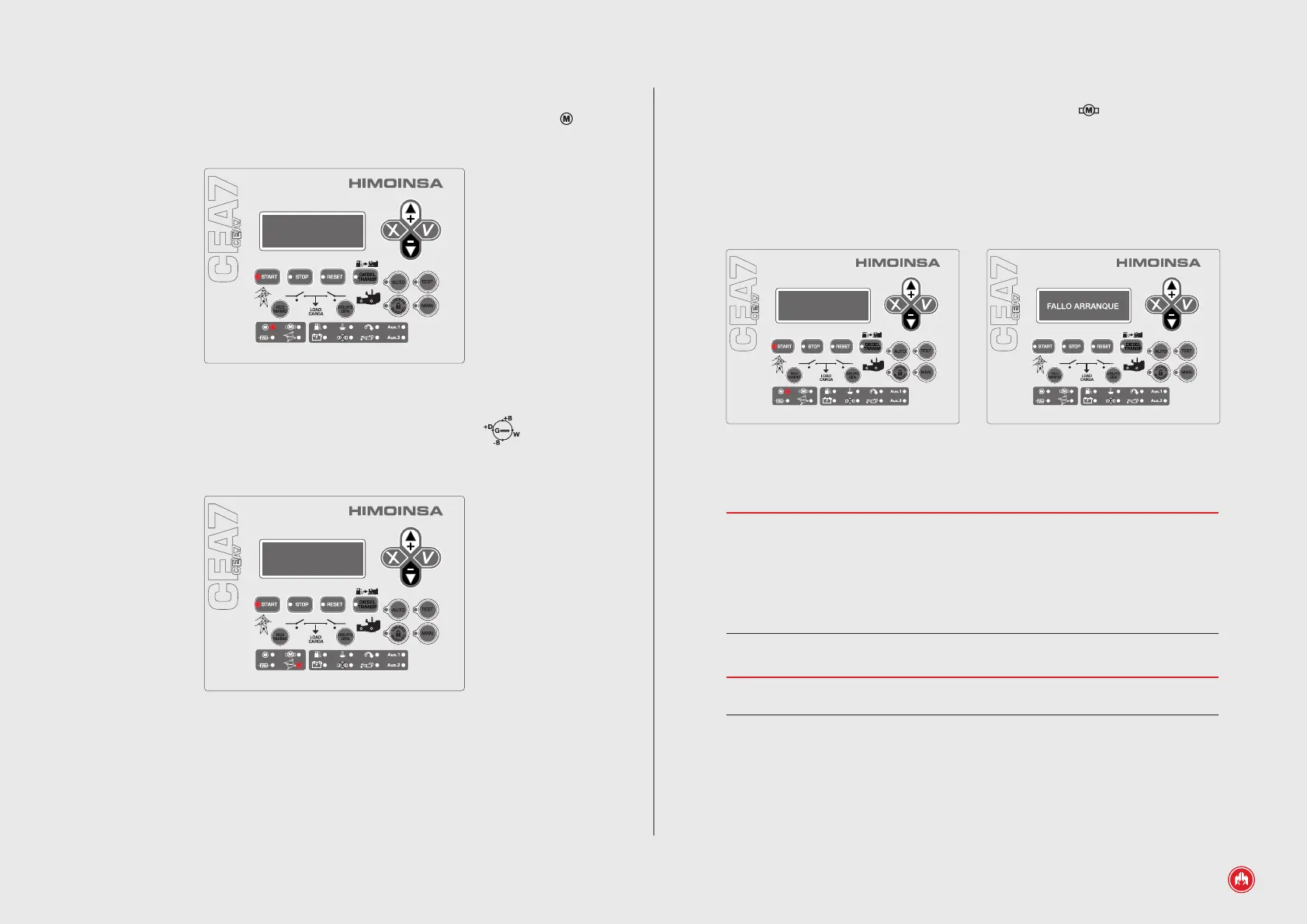

If during the set time no engine start-up is detected, the control unit waits for a

period of time (Times table, parameter 2) before retrying the start-up. Once a

certain number of start-ups has been exceeded without any start-up condition

being detected (Times table, parameter 1), the control unit activates the Start-up

Failure alarm.

During engine start-up, the excitation of the battery charging alternator is carried

out through the D+ output for a period of time (Times table, parameter 8). Once

the excitation of the alternator has been completed, the measurement module

monitors the correct functioning of the battery charging alternator. In the event a

battery charging alternator failure is detected, the Alternator Failure alarm is acti-

vated (Alarms table, parameter 10).

4. Starting the motor (ARR). For a maximum time (Times table, parameter 5),

the start output of the measurements module is activated while waiting to detect

at least one of the programmed start conditions. The possible engine starting

conditions are:

• Generator voltage (Regulations table, parameter 19). The motor is

considered started when a certain generator voltage is exceeded

(Threshold table, parameter 20).

• Alternator voltage (Regulations table, parameter 20). The motor is

considered started when a certain battery charging alternator voltage

is exceeded (Threshold table, parameter 21).

• Pickup frequency (Regulations table, parameter 21). The motor

is considered started when a certain pickup frequency is exceeded

(Threshold table, parameter 22). To activate the pickup calculation

via the engine ring gear, it is necessary to enter the number of teeth

on the engine's ywheel ring gear (Threshold table, parameter 24);

if the number of teeth for the ywheel ring gear is zero, the pickup

frequency is calculated via the generator frequency according to the

ratio 50Hz/1500rpm, 50Hz/3000rpm or 60Hz/1800rpm (Regulations

table, parameter 26).

• Low Oil Pressure Signal (Regulations table, parameter 22). Due to its

characteristics, it is not advisable to use the low oil pressure signal to

detect if the engine is running, but its use is recommended as protection

against a restart, as the engine is already running. Exceptions to this

engine start detection are SCANIA engines and sensors that have their

own power source.

5. Generator stabilisation. Once any start-up condition is detected, the control

unit waits for a xed time for stabilization of the generator signal before monitor-

ing the quality of the generator signal.

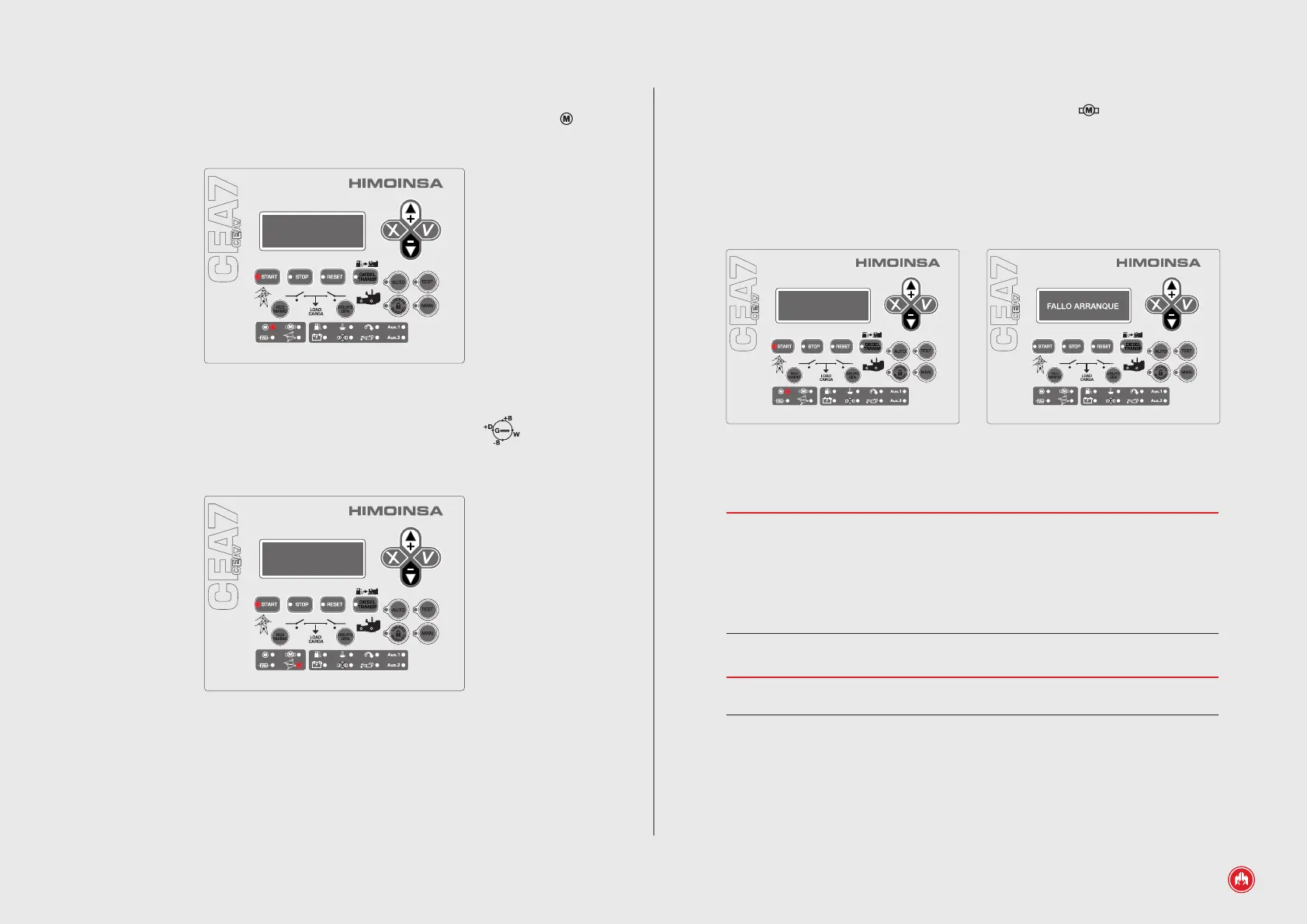

6. Rated condition. After achieving engine stabilisation, verication of the gener-

ator signal is performed. In this state, the quality of the signal produced by the

genset is evaluated (voltage levels, frequency,...).

Loading...

Loading...