S1 series standard inverter

-227-

Chapter 13 STO function description

Reference standards: IEC 61508-1, IEC 61508-2, IEC 61508-3, IEC 61508-4, IEC 62061, ISO

13849-1, and IEC 61800-5-2

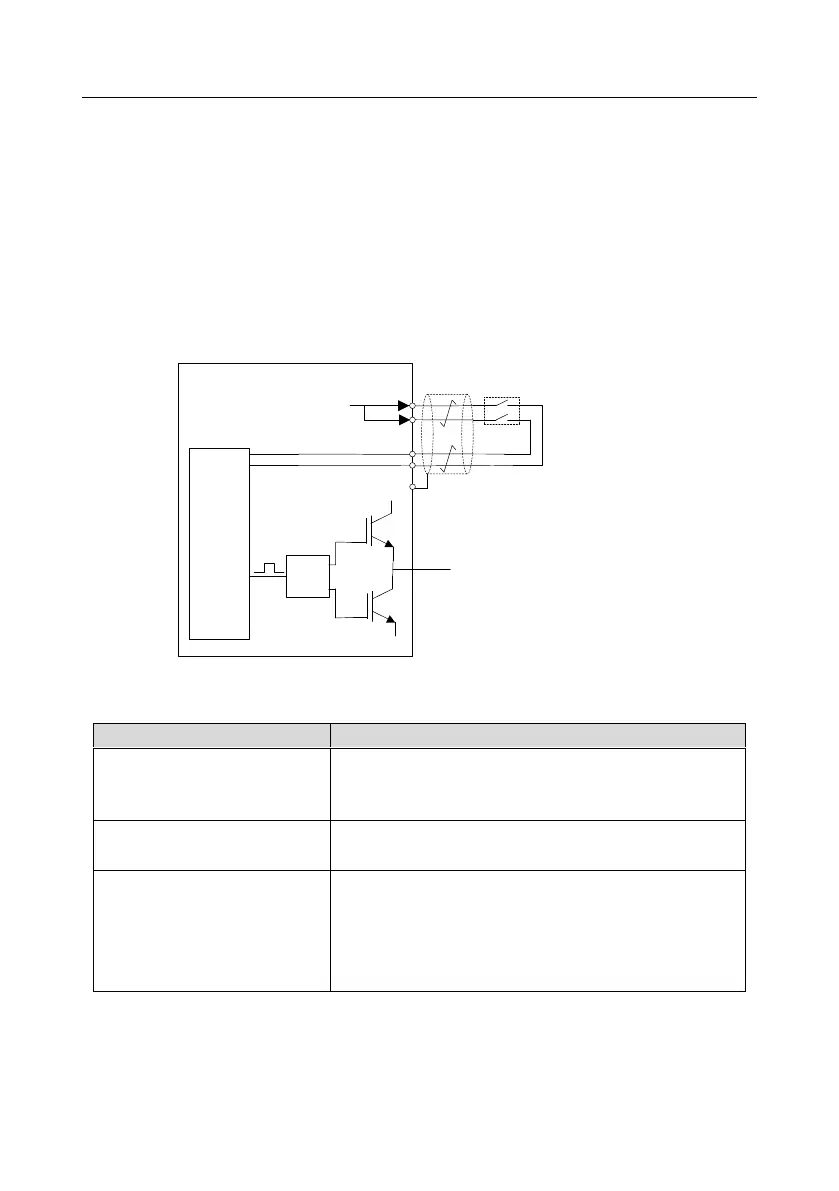

You can enable the safe torque off (STO) function to prevent unexpected startups when the main

power supply of the drive is not switched off. The STO function switches off the drive output by turning

off the drive signals to prevent unexpected startups of the motor (see the following figure). After the

STO function is enabled, you can perform some-time operations (such as non-electrical cleaning in

the lathe industry) and maintain the non-electrical components of the device without switching off the

drive.

Control

circuit

+24V

Switch, relay, etc.

UDC+

UDC-

Drive

circuit

PWM+

PWM-

U/V/W

H1

H2

Note:

The contacts of the safety switch must be opened

or closed within 250 ms; and the cable that

connects the inverter to the safety switch cannot be

longer than 25 m.

COM

13.1 STO function logic table

The following table describes the input states and corresponding faults of the STO function.

H1 and H2 opened

simultaneously

The STO function is triggered, and the drive stops running.

Fault code:

40: Safe torque off (STO)

H1 and H2 closed

simultaneously

The STOP function is not triggered, and the drive runs

properly.

One of H1 and H2 opened, and

the other closed

The STL1, STL2, or STL3 fault occurs.

Fault code:

41: Channel H1 exception (STL1)

42: Channel H2 exception (STL2)

43: Channel H1 and H2 exceptions (STL3)

Loading...

Loading...