3. MACHINE SETUP

Remove the wooden crate around the la-

the.

Check the contents of the shipping con-

tainer:

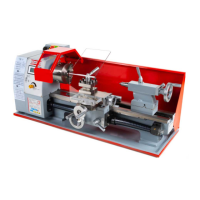

ED 400FD metal lathe

Test Flow Chart

Toolbox

Contents of the Toolbox:

See Figure 2

1 Dead center MT3

1 Dead center MT2

3 External Jaws

1 Oil gun

1 Cross screwdriver

1 Flat screwdriver

1 Key for 3-Jaw chuck

5 Hex Socket wrenches

3 Double End Head Wrenches

1 Change Gears

Unbolt the lathe from the shipping crate

bottom.

Choose a location for the lathe that:

fulls all requirements from the security

section.

With adequate lifting equipment, slowly

raise the lathe off the shipping crate bot-

tom.

DO NOT LIFT the machine by a spindle.

Make sure that the lathe is balanced be-

fore lifting it.

Lifting has to be performed by respectivel

trained persons.

ATTENTION

!

Read and understand the security and

Machine setup sections of this manual

before attempting to set-up the machi-

ne.

Failure to do so might result in machine

damage or even serious injuries!

CHECK DELIVERY CONTENT

SETTING TO WORKPLACE

To avoid twisting the bed, the lathe`s lo-

cation must be absolutely at and level.

Bolt the lathe to the stand (if used). If

using a bench, through bolt for best per-

formance. Check Figure 1 for the boring

hole distances.

Clean all rust protected surfaces using

a mild commercial solvent, kerosene or

diesel fuel. Do not use paint thinner ga-

solone or lacquer thinner. These will da-

mage painted surfaces. Cover all cleaned

surfaces with a light lm of 20W machine

oil.

Remove the end gear cover. Clean all

components of the end gear assembly

and coat all gears with a heavy, non-slin-

ging grease.

Lubricate the machine at all lubrication

points and ll the oil reservoirs to ope-

rating level before placing the lathe into

service!

Instructions for lubrication can be found

in the maintenance section of this manu-

al.

LUBRICATE ALL SLIDEWAYS LIGHTLY

BEFORE EVERY USE. LUBRICATE THE

CHANGE GEARS AND THE LEADSCREW

SLIGHTLY WITH A LITHIUM-BASED GRE-

ASE.

ENGLISH

Loading...

Loading...