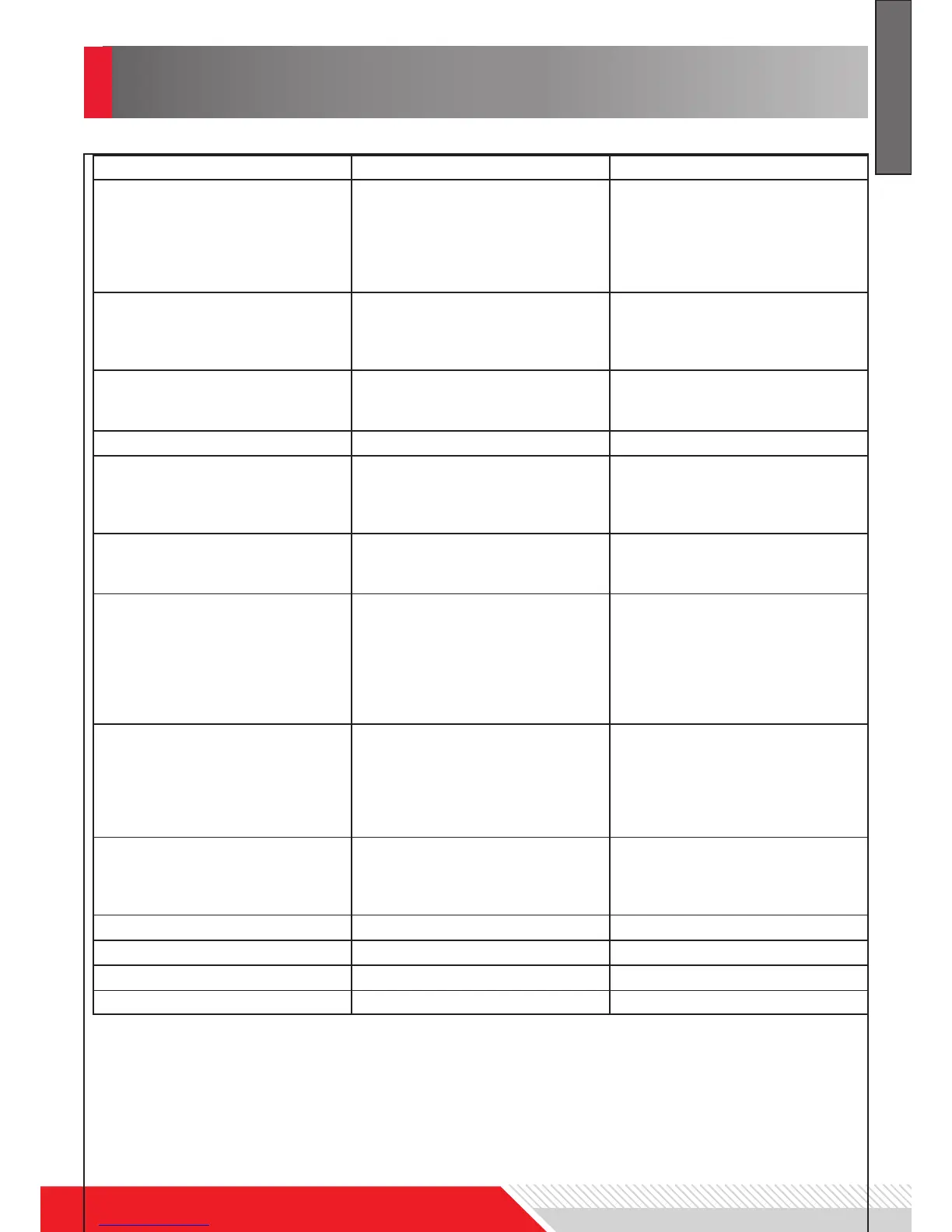

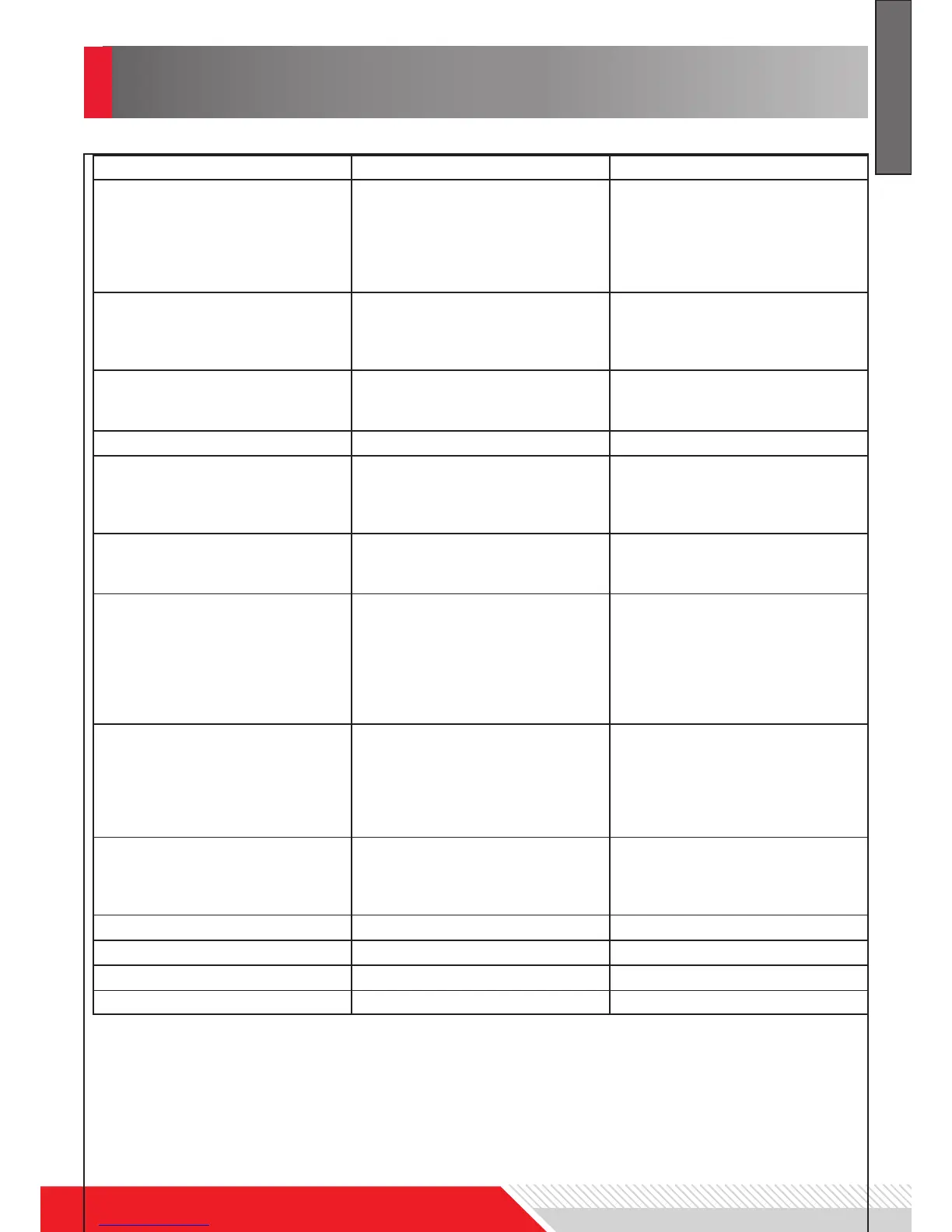

9. TROUBLESHOOTING

PROBLEM

CAUSE SOLUTION

Surface of workpiece is too

rough

Tool blunt

Tool springs

feed rate too high

radius at the tool tip too

small

resharpen the tool

Clamp tool with less over-

hang.

Reduce feeding rate

Increase the radius

Workpiece becomes coned Centers are not aligned

(tailstock has offset)

Top slide not aligned well

(cutting with the top slide)

Adjust the tailstock to the

center

Align top slide well

Lathe is chattering Feeding speed is too high

Slack in machine bearing

Reduce Feeding speed

Adjust the main bearing

Center runs hot Workpiece has expanded Loosen tailstock center

Tool has a short edge life Cutting speed too high

Crossfeed too high

Insufcient cooling

Reduce cutting speed

Lower crossfeed (nishing

allowance should not ex-

ceed 0.5mm)

Flank wear too high Clearance angle too small

Tool tip not adjusted to

center high

Increase clearance angle

Correct height adjustment

of the tool

Cutting edge breaks off Wedge angle too small

(heat build-up)

Grinding crack due to

wrong cooling

Excessive slack in the

spindle bearing

Arrangement (vibrations)

Increase wedge angle

Cool uniformly

Adjust the slack in the

spindle bearing

arrangement

Cut thread is wrong Tool is clamped incorrectly

or has been started grin-

ding the wrong way

Wrong pitch

Wrong diameter

Adjust tool to the center

Grind angle correct

Adjust the right pitch

Turn the workpiece to the

correct diameter

Spindel does not activate Emergency stop switch ac-

tivated

Unlock/release the emer-

gency stop switch

ENGLISH

Loading...

Loading...