6. OPERATION

The head spring holding xture is cylind-

rical. Loosen three set screws A and nuts

(See Figure 14 - only two are visible on

the picture).

Position the new chuck and x it using

the same set screws and nuts.

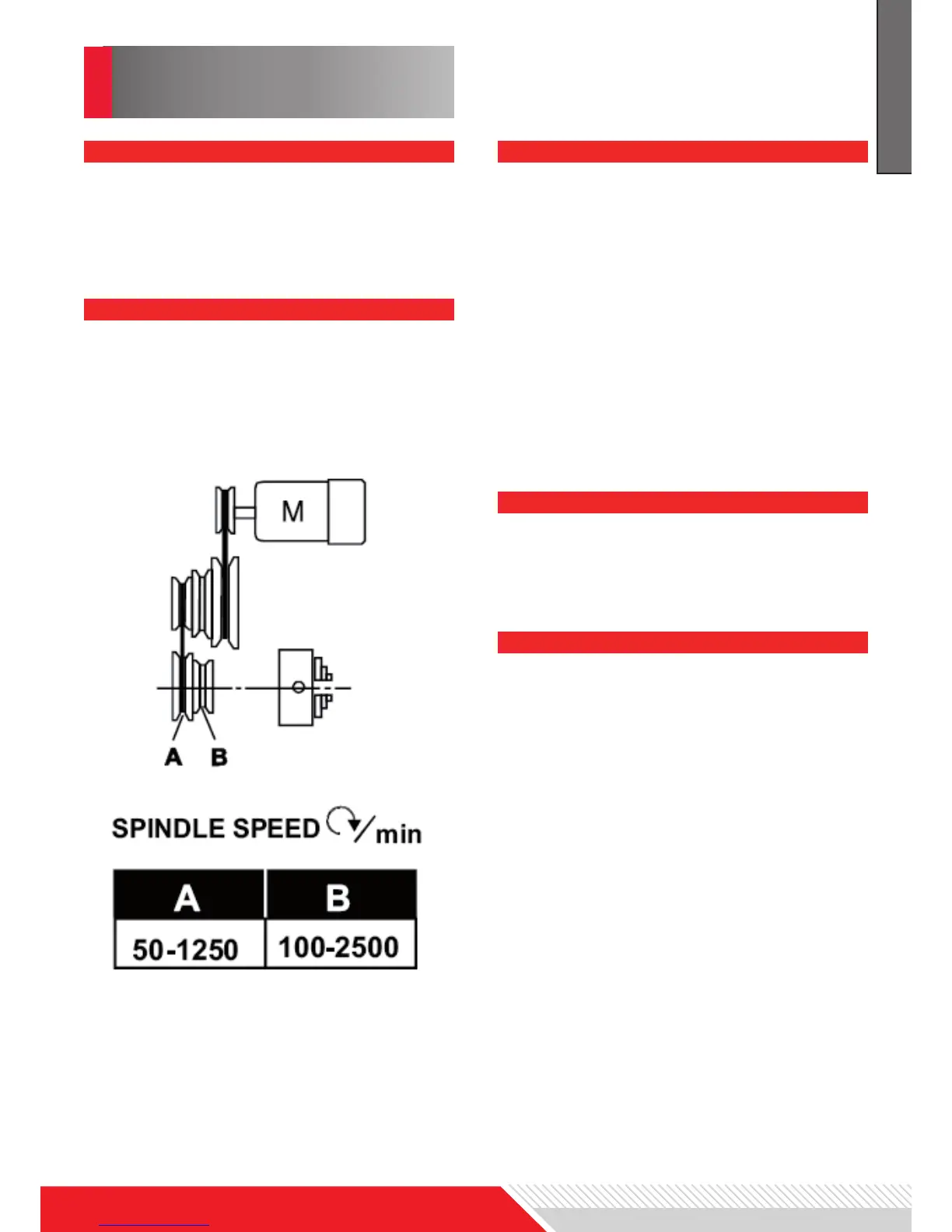

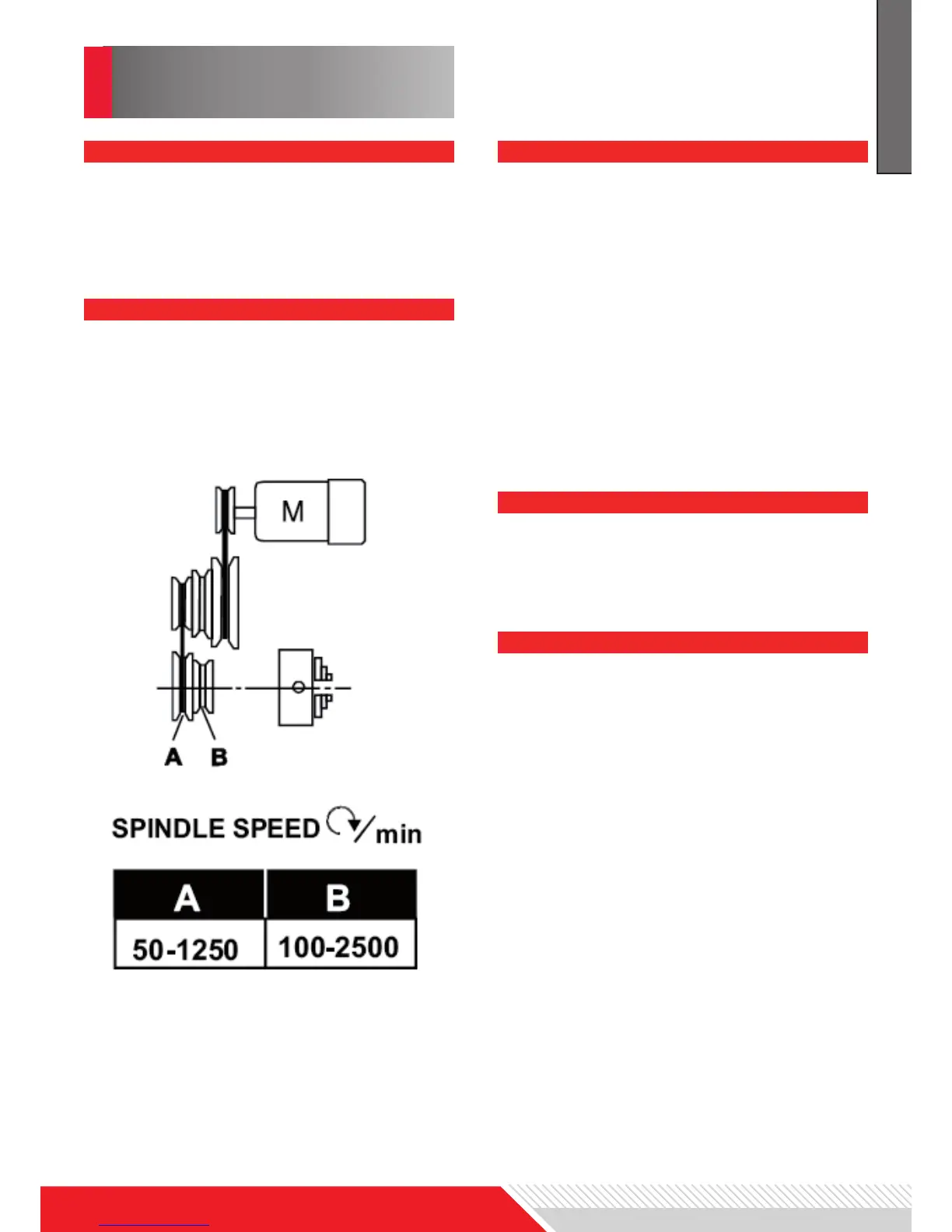

1. See Figure 16

Unscrew the two fastening screws

B and remove the protective cover.

2. See Figure 17

Adjust the V-belt C to the

corresponding position.

There are two V-belt positons:

Pos. A (outer pulleys) for lower speed

range.

Pos. B (inner pulleys) for higher speed

range.

3. Tighten the tension pulley and

fasten the nut again.

REPLACEMENT OF CHUCK

CHANGE SPEED

TOOL SET-UP

Clamping the turning tool into the tool-

holder.

The tool must be clamped rmly. When

turning, the tool has a tendency to bend

under the cutting force generated during

the chip formation. for best results, tool

overhang should be kept to a minimum

of 3/8“ (~ 9mm) or less.

The cutting angle is correct when the cut-

ting edge is in line with the center axis

of the workpiece. The correct height of

the tool can be achieved by comparing

the tool point with the point of the center

mounted in the tailstock. If necessary,

use steel spacer shims under the tool to

get the required height (see Figure 15).

See. Figure 19

Apron travel, cross travel and top slide

handwheel can be operated for longitudi-

nal or cross feeding.

See. Figure 18

Use the table A on the lathe for selecting

the feed speed or the thread pitch. Ad-

just the change gear if the required feed

or thread pitch cannot be obtained with

the installed gear set.

1. Disconnect the machine from the

power source.

2. Unscrew the two fastening screws

and remove the protective cover.

MANUAL TURNING

LONGITUDINAL TURNING WITH AUTO-FEED

ENGLISH

Loading...

Loading...