3. 2 CYLINDER HEAD

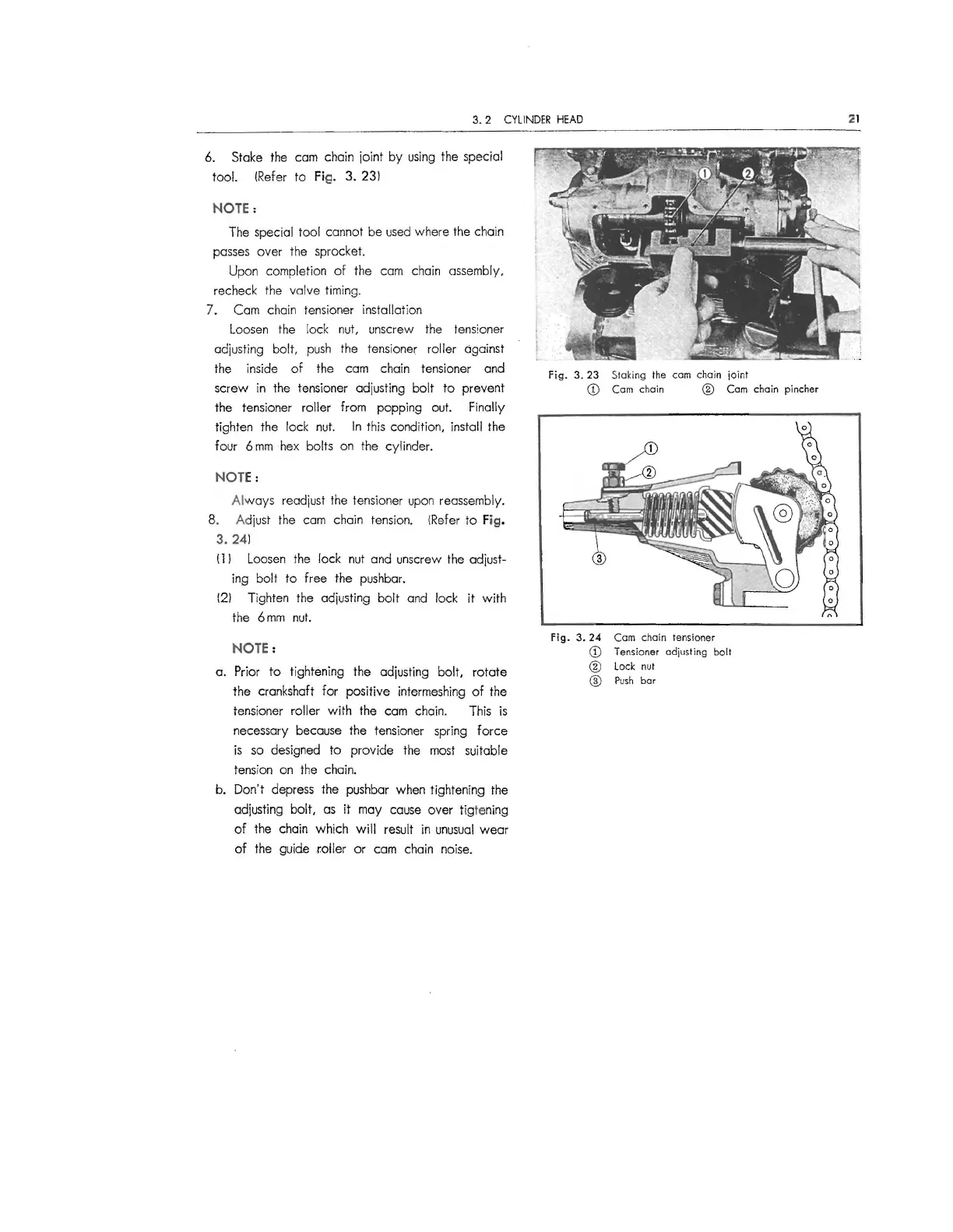

6. Stake the cam chain joint by using the special

tool. (Refer to

Fig. 3. 23)

NOTE:

The special tool cannot be used where the chain

passes over the sprocket.

Upon completion of the cam chain assembly,

recheck the valve timing.

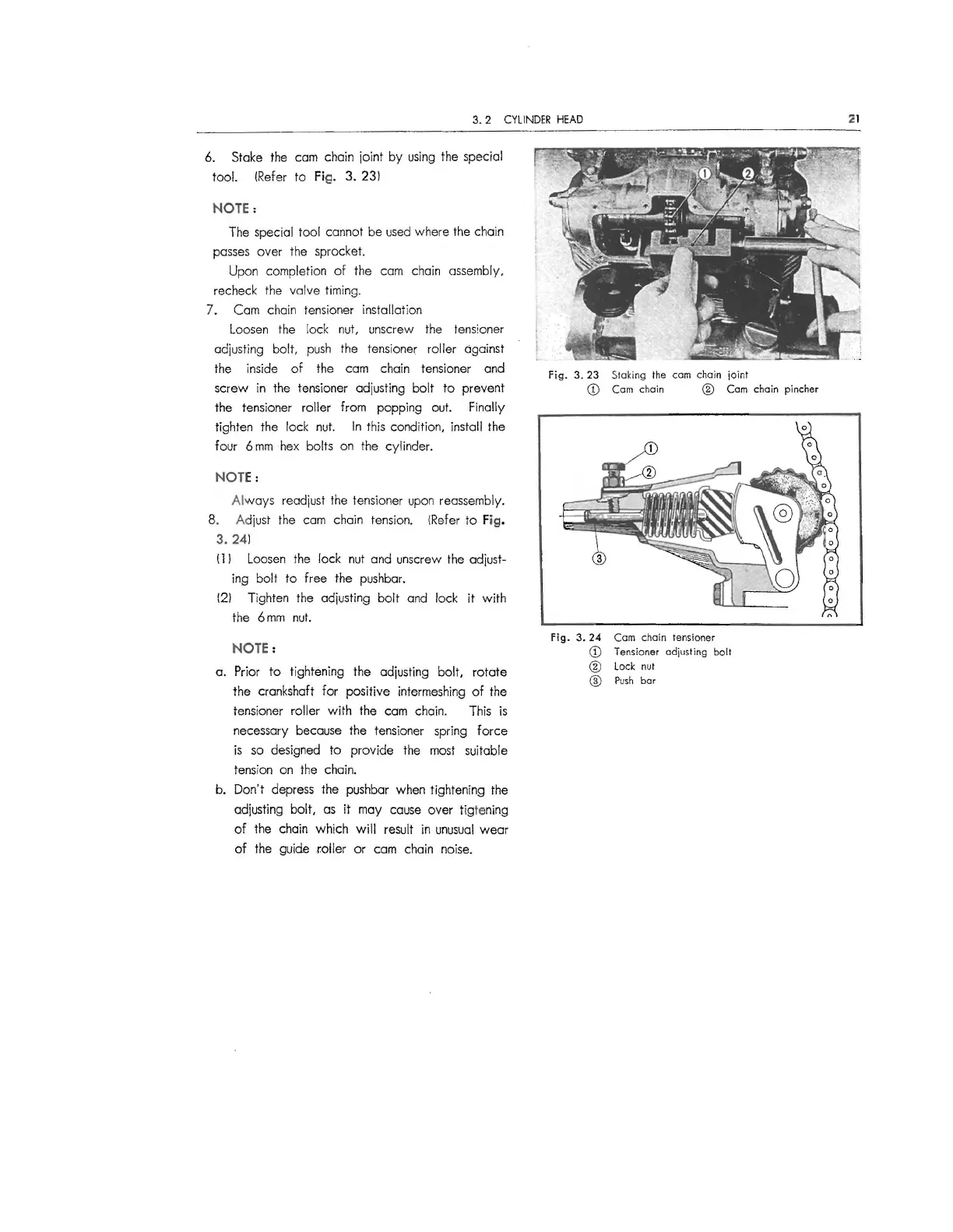

7. Cam chain tensioner installation

Loosen the lock nut, unscrew the tensioner

adjusting bolt, push the tensioner roller against

the inside of the cam chain tensioner and

screw in the tensioner adjusting bolt to prevent

the tensioner roller from popping out. Finally

tighten the lock nut. In this condition, install the

four 6 mm hex bolts on the cylinder.

NOTE:

Always readjust the tensioner upon reassembly.

8. Adjust the cam chain tension. (Refer to

Fig.

3. 24)

( l l Loosen the lock nut and unscrew the adjust-

ing bolt to free the pushbar.

(2) Tighten the adjusting bolt and lock it with

the 6mm nut.

NOTE:

a. Prior to tightening the adjusting bolt, rotate

the crankshaft for positive intermeshing of the

tensioner roller with the cam chain.

This is

necessary because the tensioner spring force

is so designed to provide the most suitable

tension on the chain.

b. Don't depress the pushbar when tightening the

adjusting bolt, as it may cause over tigtening

of the chain which will result in unusual wear

of the guide

roller or cam chain noise.

Fig . 3. 23 Staking the cam chain joint

© Cam chain ® Cam chain pincher

Fig.

3. 24 Com chain tensioner

© Tensioner adjusting bolt

® Lock nut

@ Push bar

:21

Loading...

Loading...