3. 2 CYLINDER HEAD

31

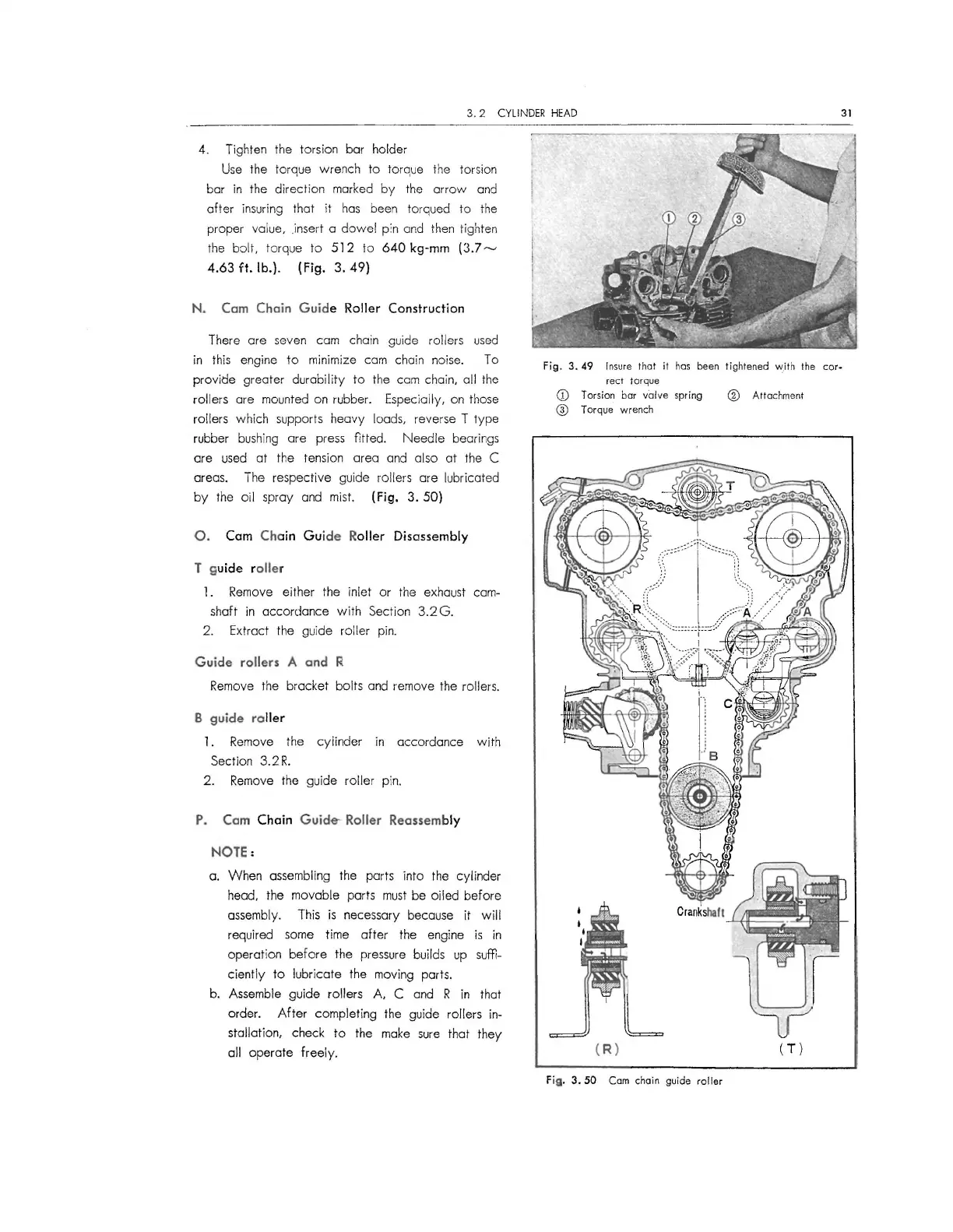

4. Tighten the torsion bar holder

Use the torque wrench to torq ue the torsion

bar in the direct ion marked by the arrow and

after insuring that it has been torqued to the

proper value, insert a dowel

p;n and then tighten

the bolt, torque to

512 to 640 kg-mm (3.7-

4.63 ft. lb.). (Fig. 3. 49)

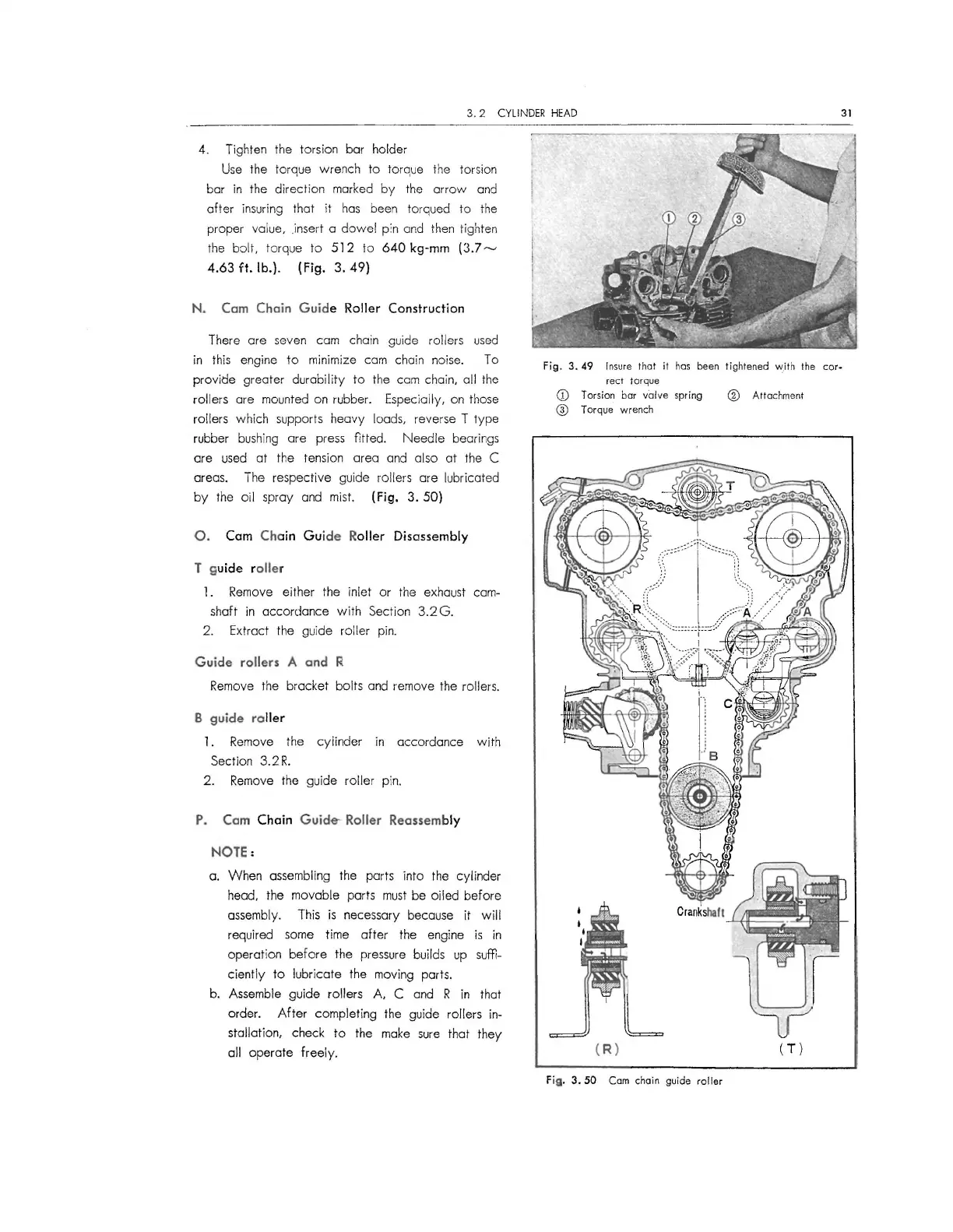

N. Cam Chain Guide Roller Construction

There ore seven cam chain guide roller s used

in this engine to minimize cam chain noise. To

provide greater durability to the cam chain, all the

rol lers ore mounted on rubber. Especially, on those

rollers which supports heavy loads, reve rse T type

rubber bushing are press fitted . Needle bearings

are used at the tension area and also at the C

areas. The respective guide rollers are lubricated

by the oil spray and mist.

(Fig. 3. 50)

0. Cam Chain Guide Roller Disassembly

T guide roller

1 . Remove either the inlet or the exhaust cam-

shaft in accordance with Section 3.2G.

2. Extrac t the guide rolle r pin.

Guide rollers A and R

Remove the bracket bolts and remove the rollers.

B guide roller

1. Remove the cyli nder in accordance with

Section 3. 2

R.

2. Remove the guide roller pin.

P. Cam Chain Guide- Roller Reassembly

NOTE:

a. When assembling the parts into the cylinder

head, the movable parts must be oiled before

assembly. This is necessary because it will

required some time ofte r the engine is in

operation before the pressure builds up suffi-

ciently to lubricate the moving ports.

b. Assemble guide rollers

A, C and R in that

order. After complet ing the guide rollers in-

stallation, check to the make sure that they

all operate free ly.

Fig. 3. 49 Insure that it hos been ti ghtened w.ith the cor-

rect torque

CD Torsion bar valve spring

@ Torque wre nch

( R)

Fig. 3. 50 Com chai n guide roller

® Attachment

(T)

Loading...

Loading...