3. 5 UPPER AND LOWER CRANKCASE

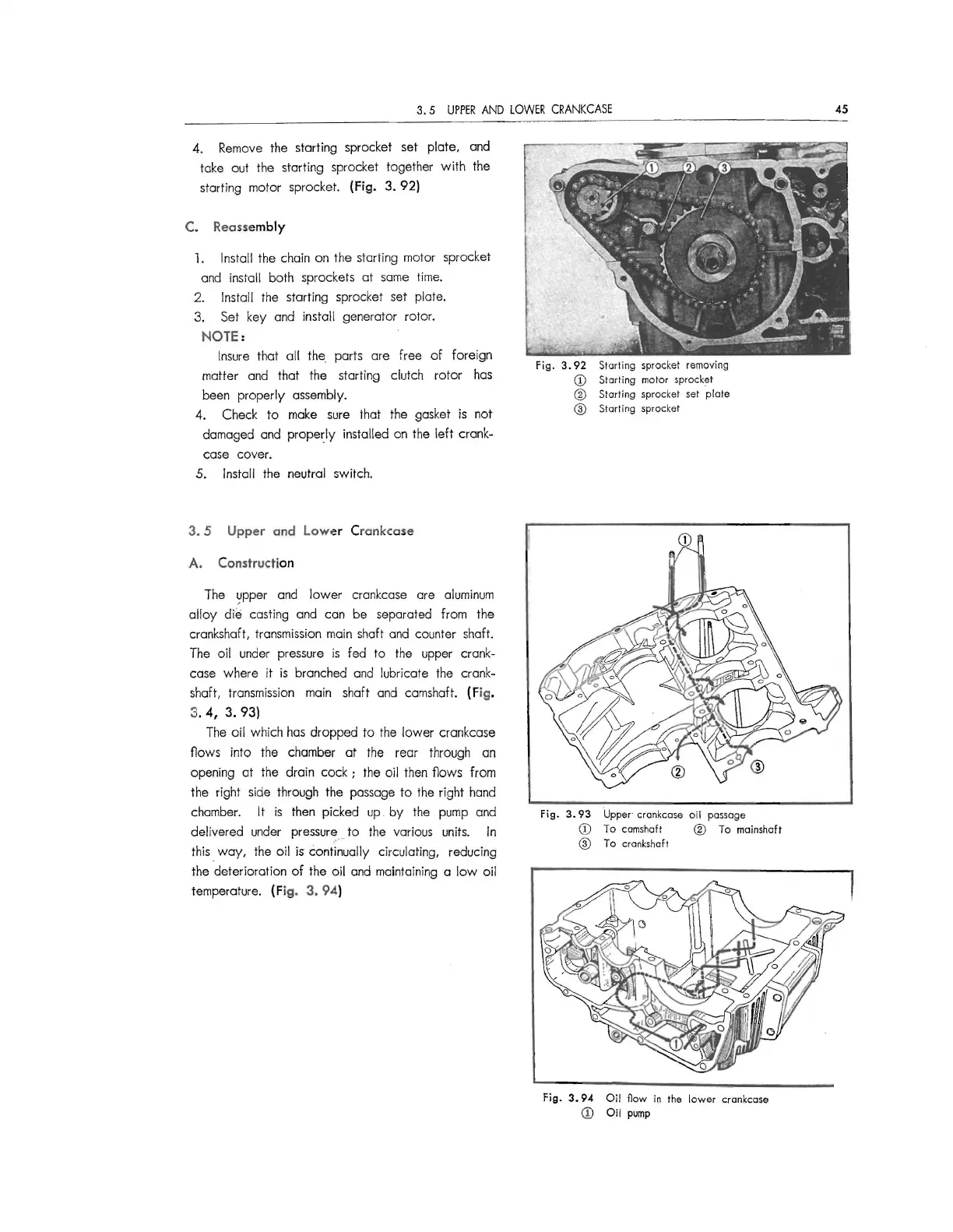

4. Remove the starting sprocket set plate, and

take out the starting sprocket together with the

starting motor sprocket.

(Fig. 3. 92)

C. Reassembly

l. Install the chain on the starting motor sprocket

and install both sprockets at same time.

2. Install the starting sprocket set plate.

3. Set key and install generator rotor.

NOTE:

Insure that all the parts are free of foreign

matter and that the starting clutch rotor has

been properly assembly.

4. Check to make sure that the gasket is not

damaged and properly installed on the left crank-

case cover.

5. Install the neutral switch.

3.

5 Upper and Lower Crankcase

A. Construction

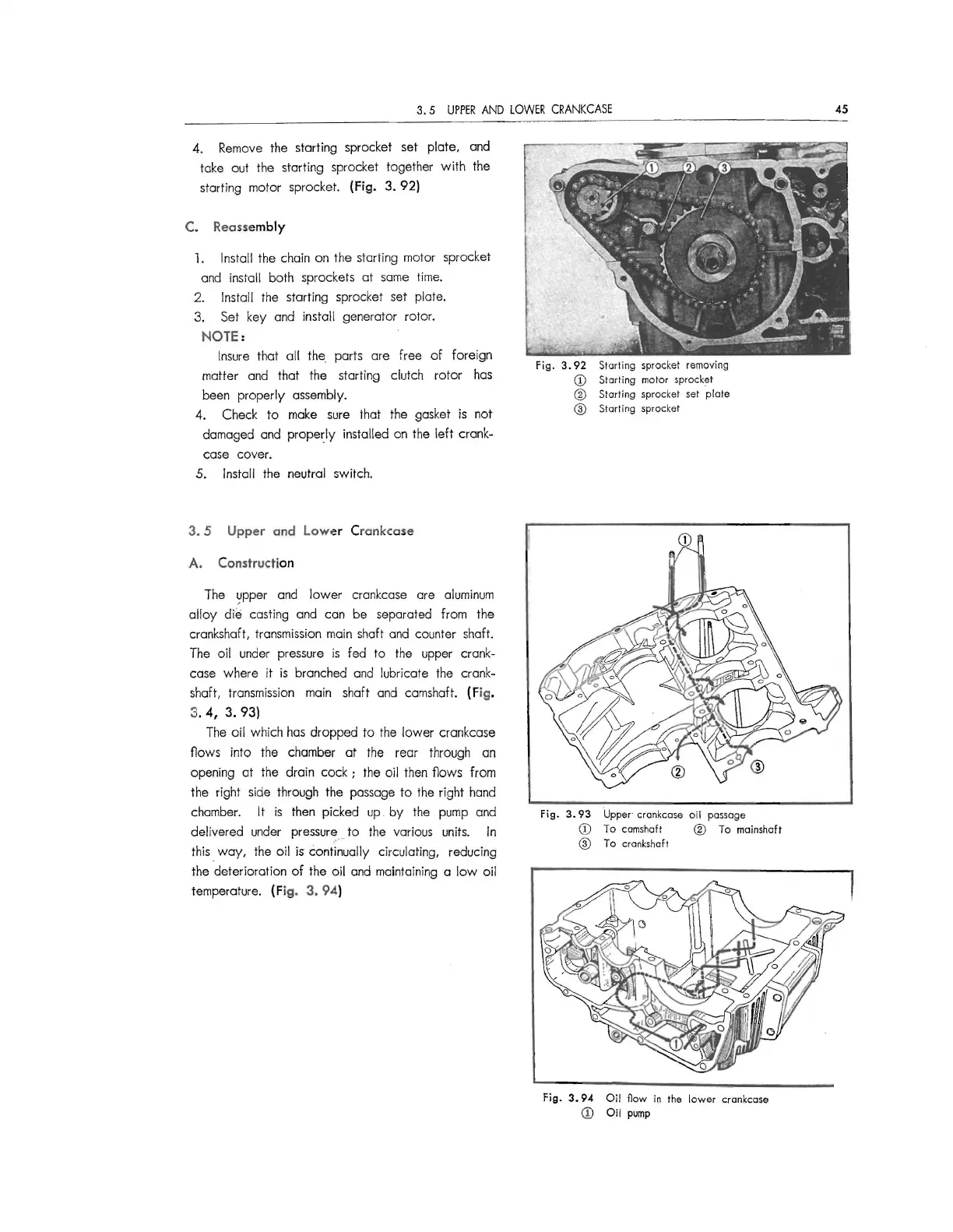

The

~pper and lower crankcase are aluminum

alloy

die costing and con be separated from the

crankshaft, transmission main shaft and counter shaft.

The oil under pressure is fed to the upper crank-

case where it is branched and lubricate the crank-

shaft, transmission main shaft and camshaft.

(Fig.

3. 4, 3. 93)

The oil which hos dropped to the lower crankcase

flows into the chamber at the rear through an

opening at the drain cock

; the oil then flows from

the right side through the passage to the right hand

chamber. It is then picked

up. by the pump and

delivered under pressurE;

.... to the various units. In

this way, the oil is continually circulating, reducing

the deterioration of the oil and maintaining a low oil

temperature.

(Fig. 3. 94)

Fig . 3. 92 Starting sprocket removing

CD Starting motor sprocket

® Starting sprocket set plate

@ Starting sprocket

fig .

3. 93 Upper· crankcase oil passage

CD To camshaft ® To mainshaft

@ To crankshaft

Fig. 3. 94 Oil flaw in the lower crankcase

CD Oil pump

45

Loading...

Loading...