A2

3. ENGINE

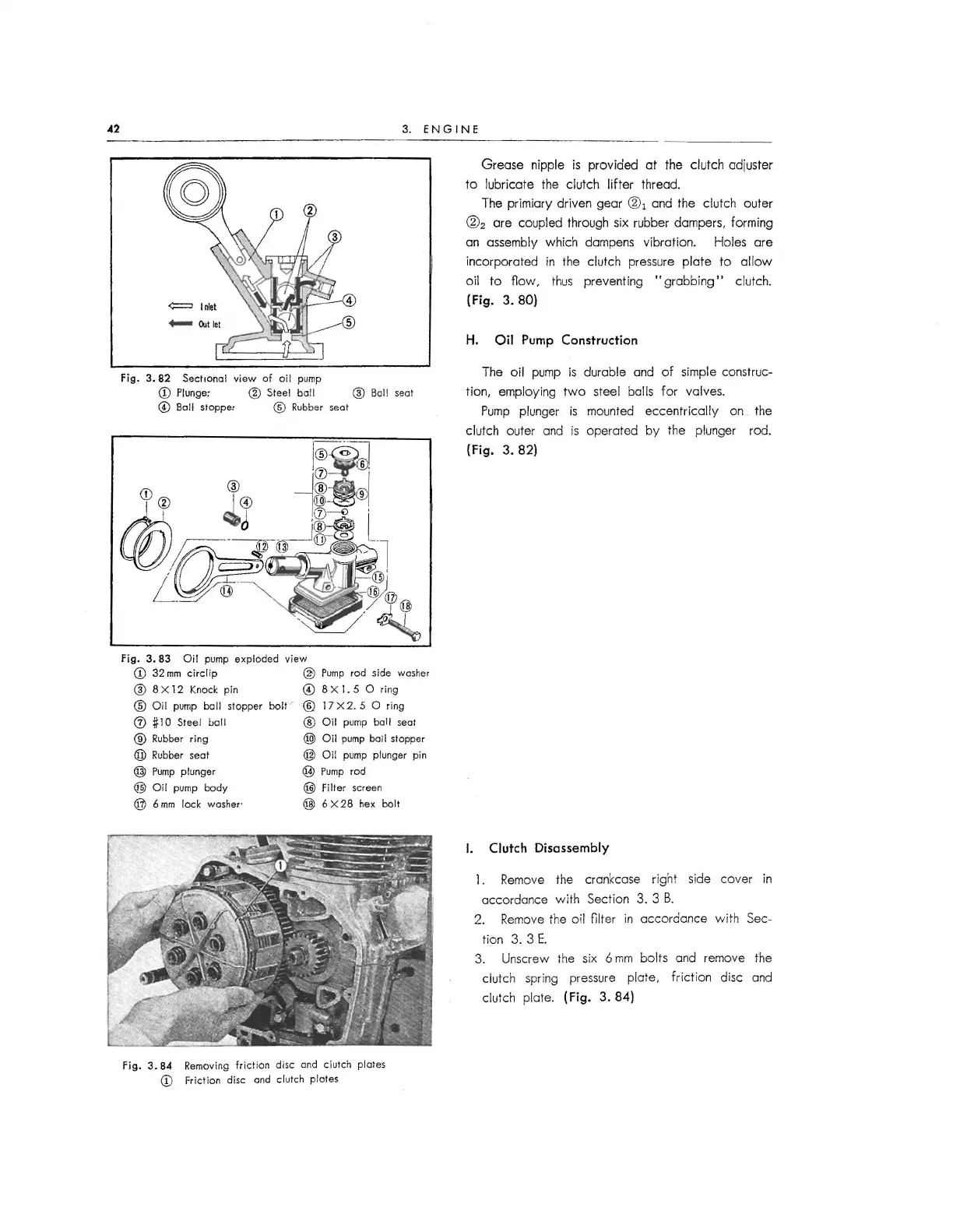

Fig. 3. 82 Sect,onal view of oil pump

CD Plunge, @ Steel ball @ Boll sear

© Ball stopper ® Rubber seat

Fig. 3. 83 Oil pump exploded view

CD 32 mm circlip ® Pump rod side washer

@ 8 X 12 Knock pin © 8 X 1. 5 0 ring

® Oil pump boll stopper bolt " ® 17X2. 5 0 ring

Cf> #10 Steel Lall @ Oil pump boll seat

® Rubber ring

@ Rubber seat

@ Pump plunger

@ Oil pump body

@ 6 mm lock wosher·

@) Oil pump boll stopper

@ O il pump plunger pin

@ Pump rod

@ Filter screen

@ 6 X28 hex bolt

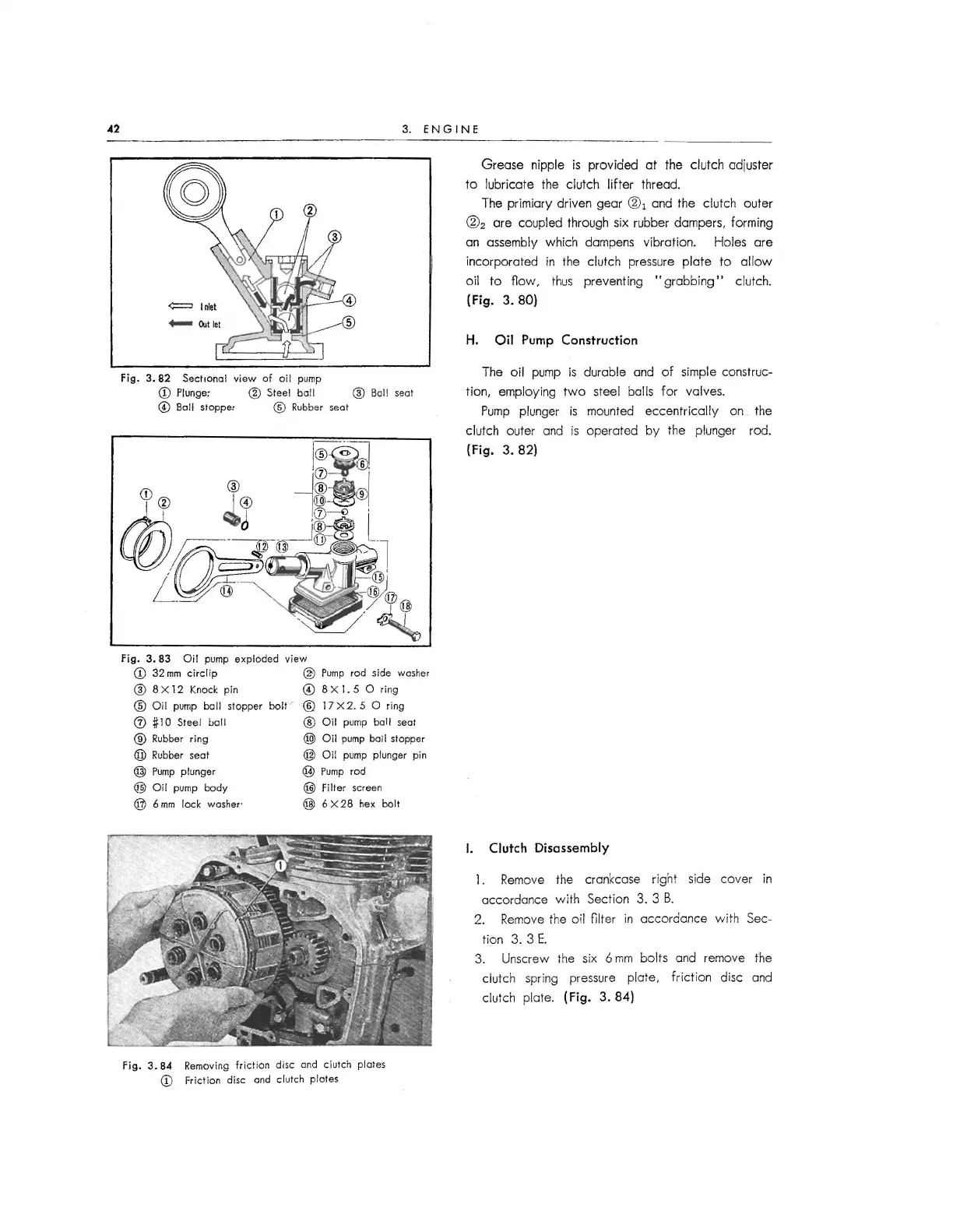

Fig. 3.

84 Removing frict ion disc and clutch plotes

CD Friction disc and clutch plates

Grease nipple is provided at the clutch adjuster

to lubricate the clutch lifter thread.

The primiary driven gear

(]:\ and the clutch outer

@

2

are coupled through six rubber dampers, forming

an assembly which dampens vibration. Holes are

incorporated in the clutch pressure plate to allow

oil to

fiow, thus preventing "grabbing" clutch.

(Fig. 3. 80)

H. Oil Pump Construction

The oil pump is durable and of simple construc-

tion , employing two steel balls for valves.

Pump plunger is mounted eccentrically on the

clutch outer and is operated by the plunger rod.

(Fig. 3. 82)

I. Clutch Disassembly

1. Remove the crankcase right side cover in

accordance w ith Section 3. 3 B.

2. Remove the oil

filter in accordance with Sec-

tion 3. 3 E.

3. Unscrew the six 6 mm bolts and remove the

clutch spring pressure plate, friction disc and

clutch plate .

(Fig. 3. 84)

Loading...

Loading...