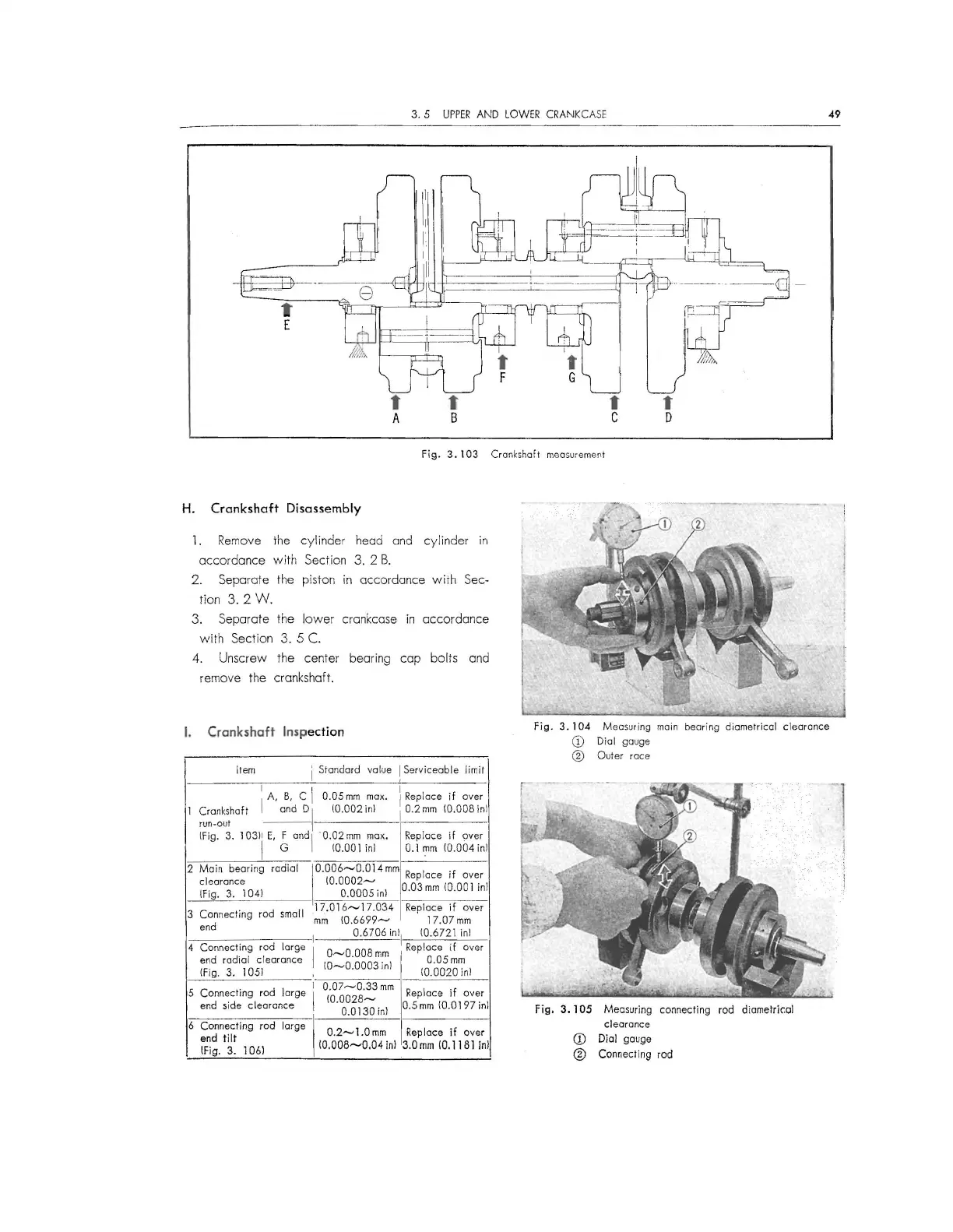

3. 5 UPPER AND LOWER CRANKCASE 49

t

A

t

B

t

C

t

D

fig. 3. 103 Crankshaft measurement

H. Crankshaft Disassembly

1. Remove the cyl inder head and cylinder in

accord ance with Sect ion 3. 2 B.

2. Separate the piston in accordance with Sec-

tion 3. 2 W.

3. Separate the lower crankcase in accordance

with Sectio n 3. 5

C.

4. Unscrew the center bearing cap bolts and

remove the crankshaft.

I. Crankshaft Inspection

Item I Standard value

[ Serviceable limit

I A, B, C I

0.05m m max,

I .

I Replace ,f over

l

Crankshaft and DI

10.002 inl

I 0.2 mm I0.008 inl

run-out -- -

!Fig. 3. 1 03)\ E,

6

and I

·o.02m m max.

Replace if over

10.001 inl

0.1 mm I0.004 inl

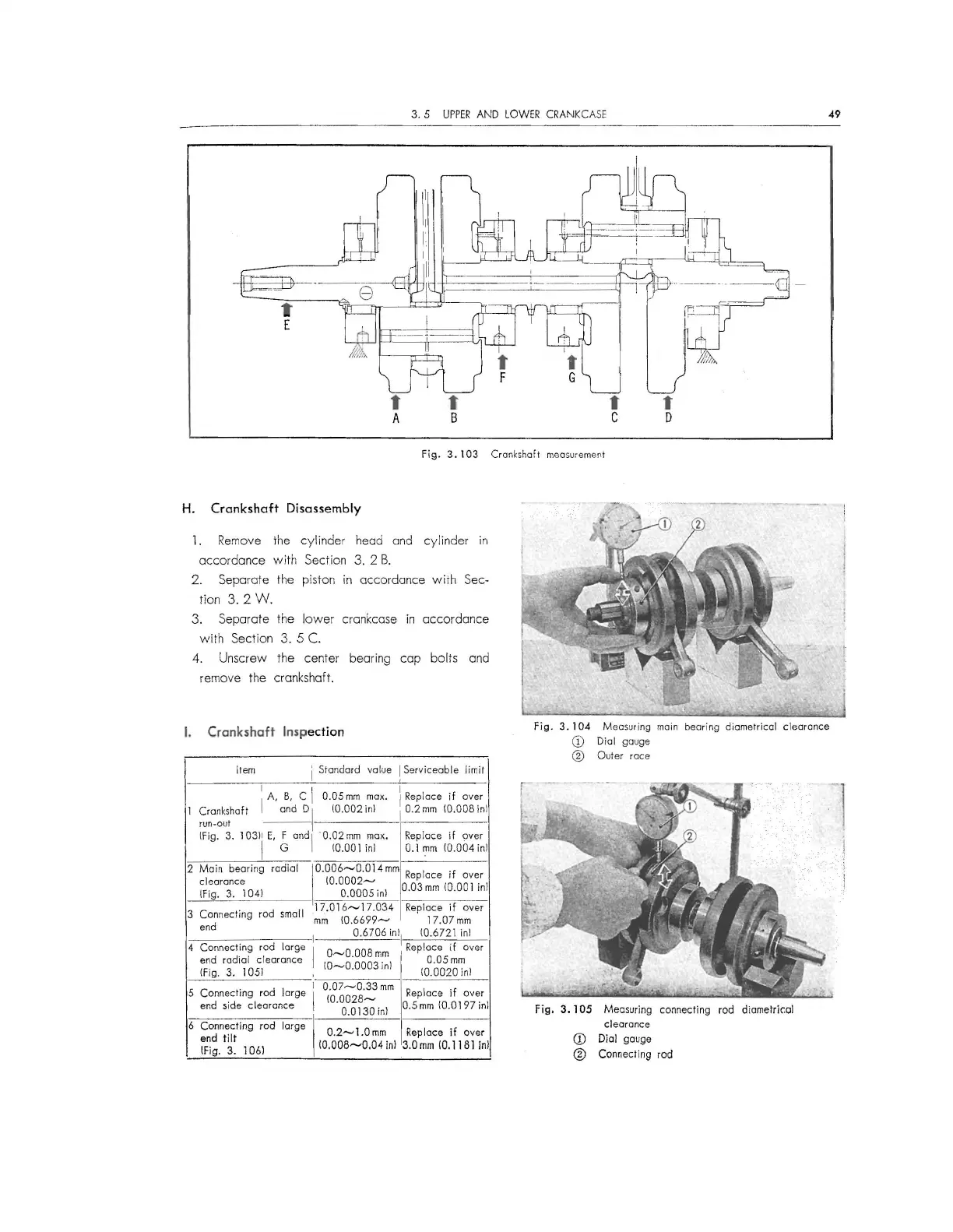

2 Main bearing

radial

I 0.006- 0.0 14 mm

Replace if over

clearance

I0.0002 -

!Fig.

3. 1041

0.0005 inl

0.03 mm 10.001 inl

3

Connecting rod

small

17.016-17.034 Replace if over

end

mm I0.6699- 17.07 mm

I

0.6706

inll 10.6721 inl

4

Connecting rod large

I

O-O.OOB mm , Replace if over

end radia l clearance

I0-0.00 03 inl IOoig

2

~~nl

!Fig. 3.

1051

I

0.07-0.33 mm

Replace if over

5 Connecting rod large

I

(0.0028-

end side clear ance

0.0130 inl

0.5 mm IO.O 197 in}

6 Connecting rod large

I

O 2

1 0

R

1

·f

d flt . - . mm ep ace I over

fF~g. ~- 106) l0,008-0 .04 inl 3.0 mm 10.1181 inl

Fig .

3. 104 Measuring main bearing diametrical clearance

CD Dial gouge

® Outer race

Fig. 3. 105 Measuring connecting rod diametric:al

clearance

CD Dial gauge

@ Connecting rod

Loading...

Loading...