Do you have a question about the Honeywell ERX and is the answer not in the manual?

Changed item text, missed labeled item, edited description.

Added Audit Trail & Display list for P3 Voltage monitoring.

Honeywell version and release date.

Measures pressure, temp, alarms, power; stores data in non-volatile memory.

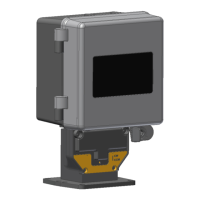

Available as wall-mounted, pipe stand, or portable units.

Uses MasterLink32, Palm Suite, or Pocket PC software.

Settings for date/time, alarms, sample/log intervals, display lists, units.

Features for pressure/temperature calibration and graphing data.

Includes serial comms, file management, and instrument security.

Use only specified battery packs to avoid voiding warranty/certifications.

Describes Sample, Display List, and Serial modes.

Uses LCD to show pre-programmed items; requires LCD.

Lower level access for instrument functions, requires 5-digit code.

Highest access level for all functions, requires 5-digit code.

Requires instrument access code for security. Default code: 33333.

Microprocessor, sensors, sample cycle, and wake-up triggers explained.

Uses strain gauge transducers; exits case via 1/1" NPT female connector.

Solid-state transducer, cable, and probe details.

Sample rates affect battery life; table shows rates vs. battery life.

Determines Audit Trail storage frequency; choices 1-24 hours.

Can store 4 or 10 items. Default: 10 items.

Table showing default items for reports and their descriptions.

8-digit display shows readings, alarms, lists.

Shows 'ALARM' or user-defined text for alarms.

Check received items, packing list for completeness.

Steps to check parts, connectors, jumpers, battery pack.

Item 576 configures recorded data (P, PT, etc.).

Table of transducer ranges, units, coefficients.

Identifies recorder to software; must be unique.

Set via computer or manually entered.

Items 586 (Sample) and 585 (Log) for setting intervals.

Configuring high/low limits for pressure and temperature.

Applies two pressures for offset and gain.

Lists required items and procedure steps.

Lists required items including barometer.

Steps for zero and span calibration using MasterLink32.

Uses low/high temperatures for offset/gain.

Probe response is nonlinear but predictable.

Fixed 50 mS width, one-time occurrence per alarm, electrical ratings.

Port for local/modem connections, baud rate setting.

Installation inside the recorder using ribbon cable.

Requires optional RS-232 to CMOS I/O Board.

Requires optional RS-232 to CMOS I/O Board with shorting plug.

Uses alarm pulse output to trigger modem call-in.

Items 333, 484, 789 configuration for pulse method.

ERX controls modem via Hayes AT commands.

ERX issues AT commands for scheduled calls.

Item 338 determines if call was alarm or scheduled.

Controls power to communication devices via alarm output.

Powers device for 30 min starting at 9:00 AM.

Powers device for 4 hours starting at 8:00 AM.

Uses Pulser-A/B outputs for fuel switching based on temperature or override.

Download item file and Audit Trail data before upgrade.

Connect MPA, serial cable, start software, configure communications.

Highly recommended to download data before upgrade.

Displays "Upgrade Complete" message.

Real-time clock active, sampling stops; LCD shows dashes.

Clock stops, sampling stops, LCD blank; requires reset.

Uses MasterLink32 software to reset instrument items.

Useful if serial link fails; involves button presses.

Tests LCD segments and indicates A/D converter faults.

Coefficients for P3 pressure and P1 board measurements.

Detailed coefficients for P1 pressure measurement.

Items 333 (Call-In Trigger) and 334 (Date).

Detailed coefficients for P2 pressure measurement.

Selects pulse output mode for fuel switching.

P3 pressure unit selection and calibration date/serial.

Defines P3 pressure range and zero offsets.

Records P3 span factors and various pressure readings.

Minimum P3 pressure and associated time/date.

User-defined limits for P3 pressure alarms.

High and low pressure readings for the current day.

Setting alarm messages and controlling alarm channel use.

Zero offset calibration constants for P1 pressure.

Span calibration factors for P1 pressure.

Zero offset calibration constants for P2 pressure.

Zero and span calibration constants for temperature.

Enables clearing of active alarms using the MI Logo.

Configures items for Display List 1.

Enables display of live pressure/temperature readings.

Selects unit of measure for pressure readings.

Selects unit of measure for temperature readings.

Controls decimal places for pressure display.

High/low pressure alarm limits for P1.

High/low pressure alarm limits for P2.

High/low temperature alarm limits.

High/low pressure alarms for P2 and transducer ranges.

Gas temperature high alarm and low alarm limit.

User-defined upper range limit for P2 pressure.

Serial numbers for P1 and P2 transducers.

Defines transducers and identifies recorder for software.

Second part of site identifier.

Setting time and date for time-stamping records.

User selected periods for logging and sampling.

Sets time for item re-zeroing and calculation start.

Selects baud rate for serial connections.

Pre-selected items for creating historical data reports.

Enables logging for calibration, alarm, serial, MI button, or changes.

Detailed coefficients for P3 pressure measurement.

Continued detailed coefficients for P3 pressure.

Maximum and minimum P1 and P2 pressure readings.

Maximum and minimum gas temperature readings.

Times and dates for P1 max/min pressure readings.

Times and dates for P2 max/min pressure readings.

Average, high, and low temperature interval readings.

Time/date for P1 interval high/low pressure readings.

Time/date for P2 interval high/low pressure readings.

Average, high, and low P1 pressure readings for the current day.

High, low, average P2 pressure readings for the current day.

High, low, average temperature readings for the current day.

Average, high, low P1 pressure readings from the previous day.

Average, high, low P2 pressure readings from the previous day.

Average, high, low temperature readings from previous day.

Times and dates for previous day P1/P2 readings.

Hysteresis bands for pressure and battery measurements.

Enables logging for alarm clearing events.

Delays for host computer communication.

Settings for modem retry attempts.

Selects call-in type (alarm pulse or AT commands).

Settings for modem power control timing.

Additional alarm levels for P3 pressure.

Hysteresis band for P2 pressure limits.

Selects item displayed on LCD in sample mode.

Two-step alarm notifications for P1/P2 pressure.

Defines low/low alarm for P2 pressure.

Sets delay for modem wake-up.

Table listing part numbers and descriptions for components.

Components for wall, pipestand, and U-bolt mounting.

Parts for the portable mounting configuration.

Components for single battery pack installation and securing.

Components for dual battery pack installation and securing.

Parts for external and internal RS-232 connections.

Components for Messenger Modem without RS-232.

Components for Messenger Modem with RS-232.

Components for 4-20 board with/without case connector.

Components for dual alkaline pack and MI modem.

Wiring diagram for Class I, Div 1, Group D hazardous locations.

Wiring diagram for Class I, Zone 0, Group IIA locations.

Important notes on barriers, power, cable length, codes.

Wiring diagram for Class I, Div 2, Group D hazardous locations.

Notes on serial port, modem, protocol translator connections.

Contact information for Mercury Instruments/Honeywell Process Solutions.

| Brand | Honeywell |

|---|---|

| Model | ERX |

| Category | Recording Equipment |

| Language | English |