14 107062-12 EN FR26 GLO 501 Printed in France

IMPROPER SYSTEM PERFORMANCE

• Consult local safety agency before designing a machine control system.

• Comply with local safety requirements when designing machine control link, interface and all control

elements that affect safety.

• Install two independent safety relay contacts into machine control stop circuit controlled by FF-SB Series

light curtain.

• Ensure two independent stop circuit relays have mechanically linked contacts that prevent contact

overlapping in the event of a welded contact.

Failure to comply with these instructions could result in death or serious injury.

FF-SB12, FF-SB14 and FF-SB15 Series light curtains are designed so a malfunction or an interruption of the

sensing field will cause the light curtain to generate a stop signal within a maximum of 30 milliseconds. This

stop signal will be generated automatically if a malfunction occurs in the light curtain. All other machine

control components that affect safety should also be designed to the same high level of operation.

IMPROPER MACHINE REACTION

• Ensure the machine control is capable of stopping the machine at any point in the cycle.

• Ensure that a loss of power does NOT impair stopping action of machine.

Failure to comply with these instructions could result in death or serious injury.

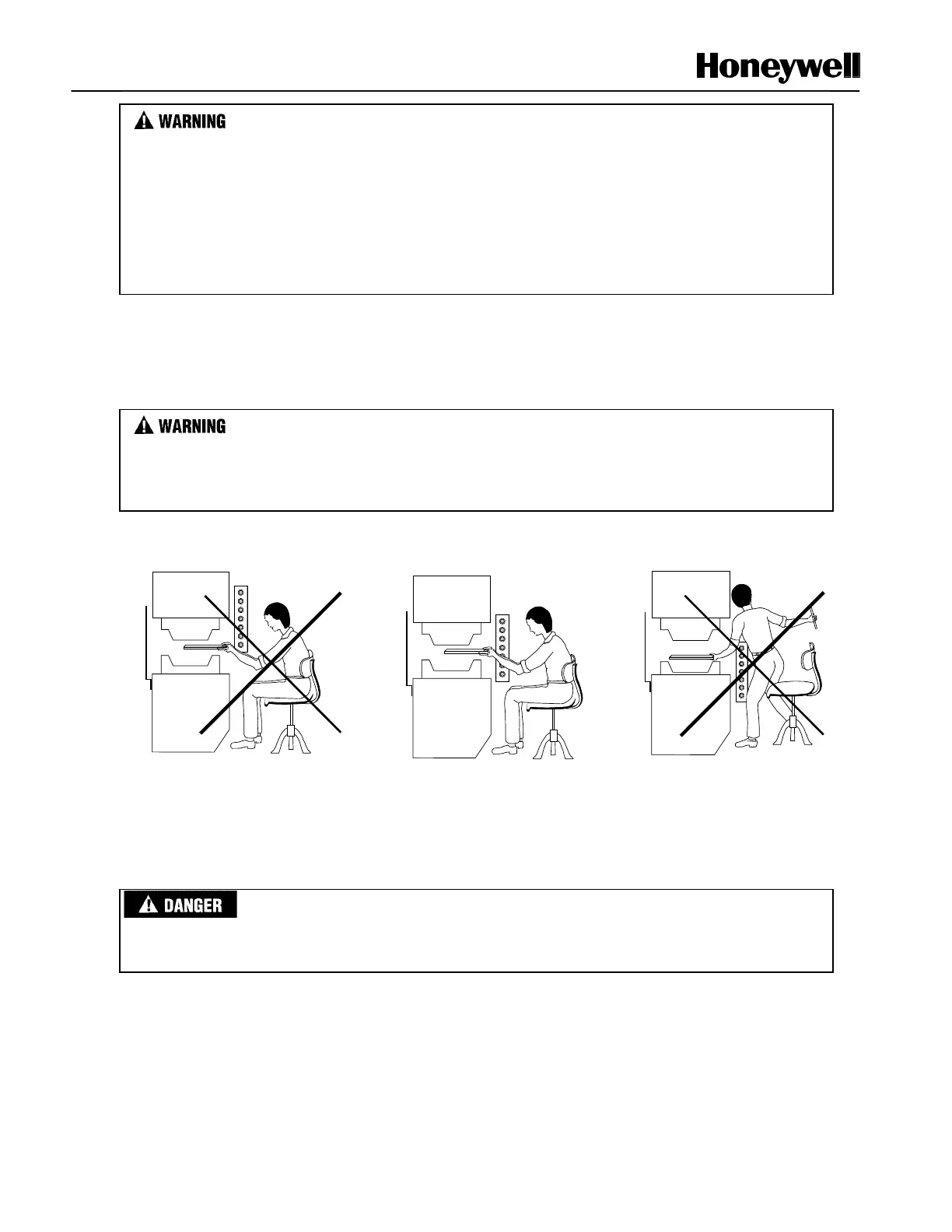

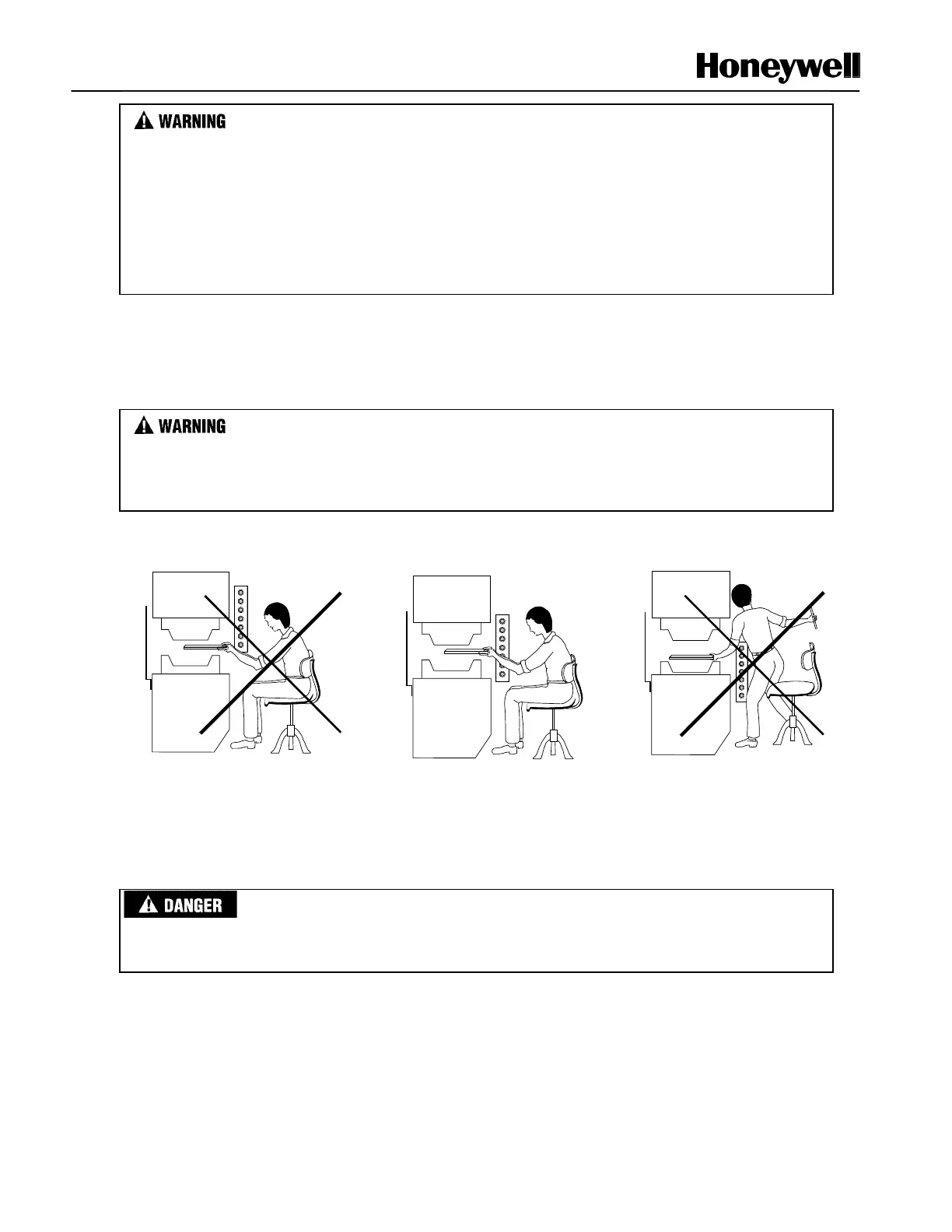

Figure 1-1 Point-of-operation Guarding (use FF-SB12 or FF-SB14 only)

Point-of-operation is defined as that area where a machine performs work (such as cutting, shaping, boring,

or forming) on a material.

FULL REVOLUTION MECHANICAL POWER PRESSES CANNOT BE STOPPED IN MID-STROKE (OSHA

29CFR 1910.217). Do NOT use FF-SB Series light curtains on full revolution mechanical power presses.

Failure to comply with these instructions will result in death or serious injury.

Mechanical guarding

Mechanical guarding

Mechanical guarding

Operator enters danger zone

under the light curtain

Operator enters danger zone

above the light curtain

Loading...

Loading...