EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

68-0237-2 4

INSTALLATION

Mounting

CAUTION

Equipment Damage Hazard.

Do not mount EMM-3U inside HVAC equipment.

Mount only on wall or on cold air return.

1. Mount the thermostats in each zone of the living space

using the installation instructions provided with each

thermostat.

2. Mount the dampers in the ductwork using the installa-

tion instructions provided with each damper.

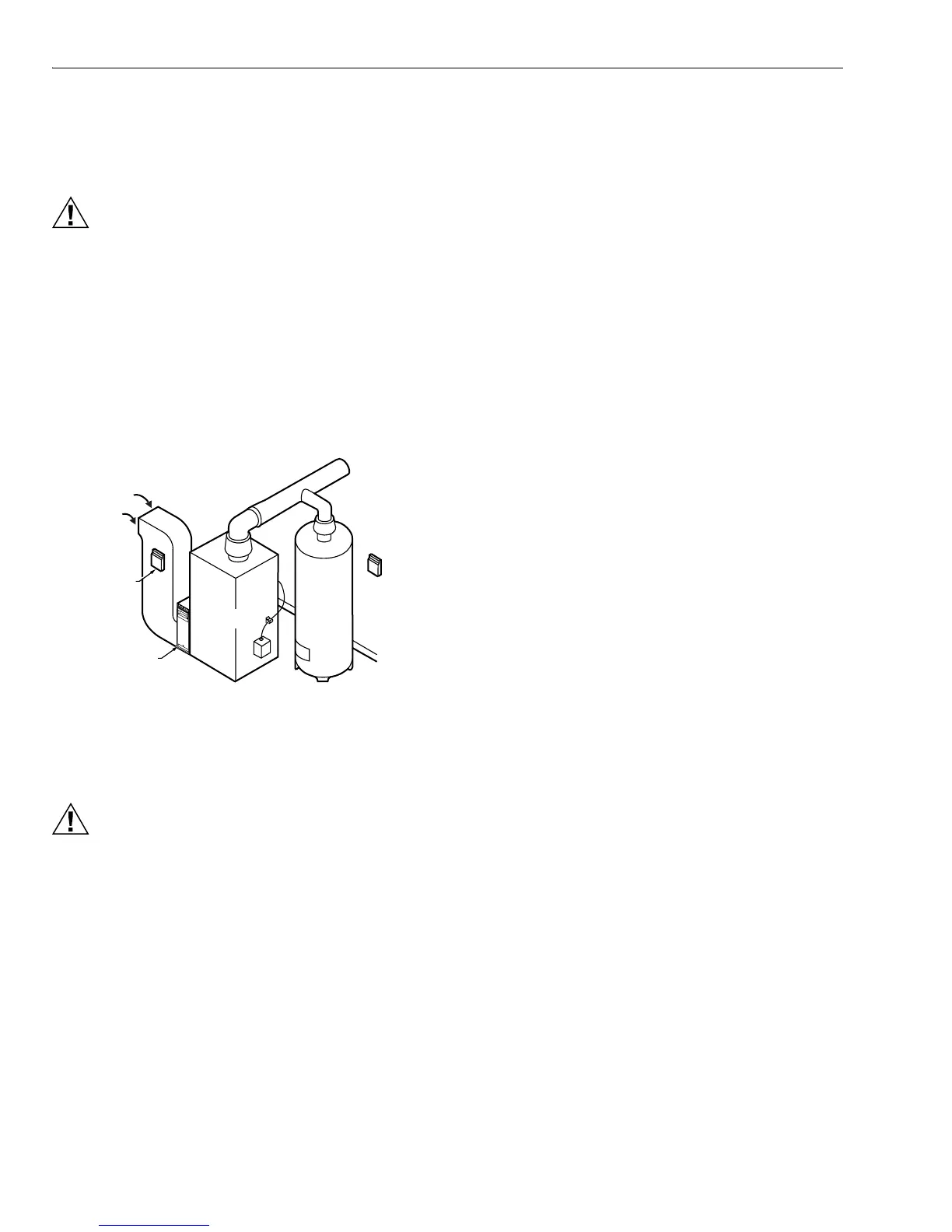

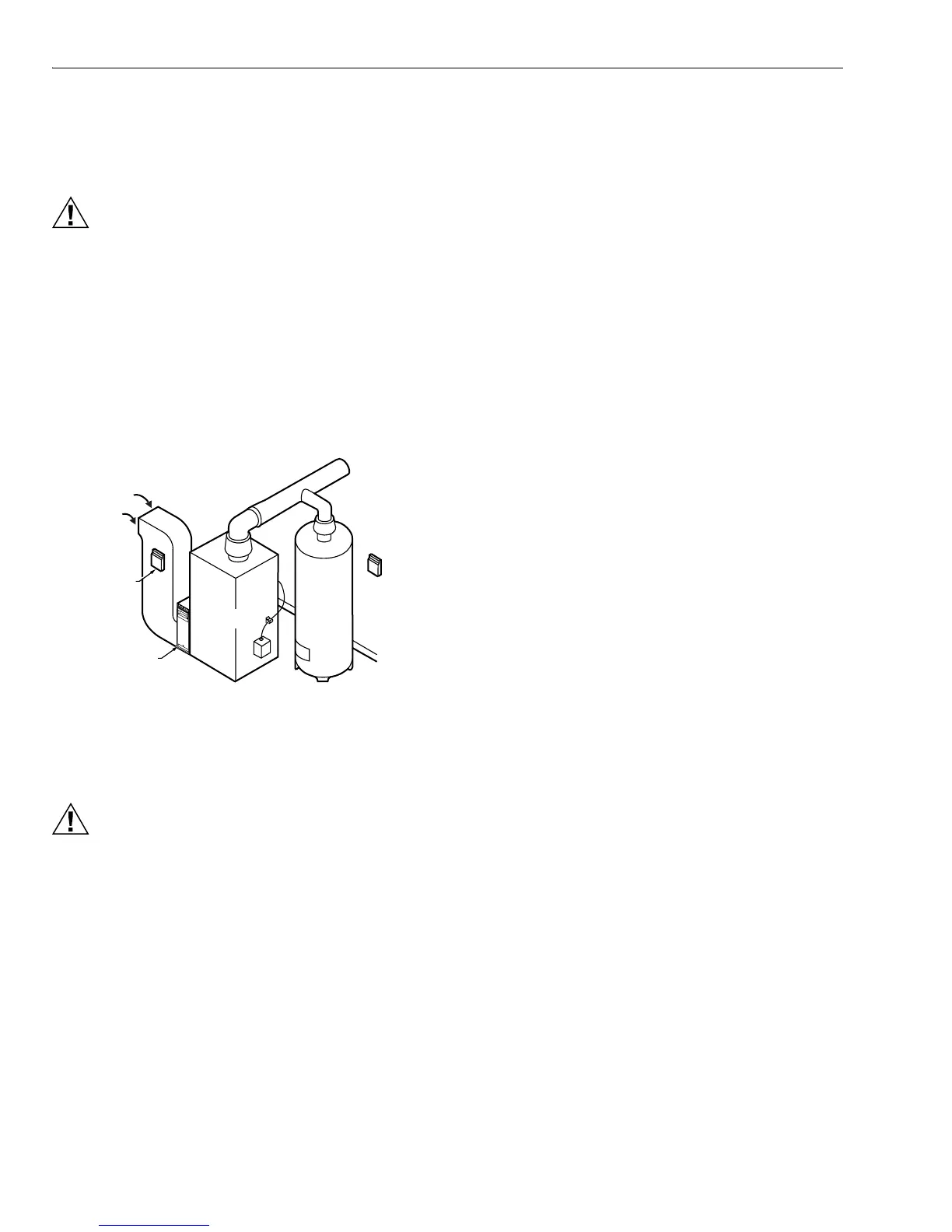

3. Mount the EMM-3U zone panel near the HVAC equip-

ment; locate it on a wall or on the cold-air return. See

Fig. 2.

4. Level the EMM-3U for appearance only.

Fig. 2. EMM-3U mounting location.

WIRING

CAUTION

Voltage Hazard.

Can cause electrical shock or equipment damage.

Disconnect power before continuing installation.

Wiring must comply with applicable codes, ordinances and

regulations.

1. Connect thermostats as shown in Fig. 3-7.

2. Connect dampers as shown in Fig. 8-12.

3. Connect C7735A1000 Discharge Air Temperature Sen-

sor (DATS) to the DATS terminals. The wires are not

polarized; see Fig. 13.

4. Connect the HVAC equipment to the EQUIP terminals

on the panel; see Fig. 13-18.

5. Connect a 40 VA, 24 Vac transformer to R (hot) and C

(common). This must be a dedicated transformer. See

Fig. 13.

Thermostat Wiring

Conventional Equipment

Conventional (RWYG) thermostats can be used to control

conventional, multi-stage and heat pump equipment. When

single-stage thermostats are used, stages are engaged

through the on-board 5 - 60 minute timer. If the equipment is a

heat pump, the EMM-3U panel controls the reversing valve. If

the thermostat has a common terminal, it is wired to C on the

panel, see Fig. 3. Multi-stage conventional (non-heat pump)

thermostats are wired with the second stage of heat and cool

on the thermostat to W2 and Y2 on the panel. Leave the O/B

thermostat jumper on the EMM-3U disconnected.

The PC8900 can be used as a zone thermostat. See Fig. 4 for

hookup. The PC8900 with the W8900A or C controls up to 2

heat and 2 cool stages of conventional equipment. The

PC8900 with the W8900A also controls heat pump

equipment.

Connect a jumper on the W8900 from Rc to Rh as shown.

Wire terminals R and C to a transformer. Alternately, if the

zone control system current draw is within specifications, the

R and C on the W8900 could be connected to R and C on the

EMM-3U. The PC8900/W8900 draws 5 VA.

Heat Pump Equipment

Select a heat pump thermostat from Table 1. If the thermostat

selected has a separate Y1 and W1 wire, connect as shown in

Fig. 5, leaving the zone O/B thermostat type jumper on the

EMM-3U disconnected

If the PC8900/W8900A is used, wire as shown in Fig. 4. This

hookup engages second stage heat based on thermostat

demand, but the Em Heat switch on the panel must be used to

switch the panel to emergency heat.

NOTE: The thermostat Em Heat switch does not switch the

panel to emergency heat.

If the thermostat selected from Table 1 has a single Y terminal

for first stage heat and cool, wire as shown in Fig. 6 and 7.

Wire either O or B (not both) from the thermostat to the O/B

terminal on the EMM-3U. Locate the O/B thermostat jumper

on the EMM-3U near each zone thermostat wiring terminal.

Connect the jumper if O is used or leave the jumper

disconnected if B is used. Connect second stage, auxiliary

heat, to W2.

Conventional single stage thermostats can be used to control

a heat pump if wired as shown in Fig. 3. In this case, the panel

operates the reversing valve, the second stage is brought on

by the panel stage timer, and emergency heat is activated by

the EM heat switch on the panel. Leave the O/B thermostat

type jumper disconnected when using conventional

thermostats.

M14762

WATER

HEATER

EMM-3

E

L

E

C

T

RO

NI

C

A

I

R CLEANER

RETURN

AIR

EMM-U3

PTIONAL

OCATION

FURNACE

OR BOILER

HIGH

EFFICIENCY

AIR CLEANER

Loading...

Loading...