EMM-3U UNIVERSAL ELECTRONIC MINIZONE™ PANEL

9 68-0237-2

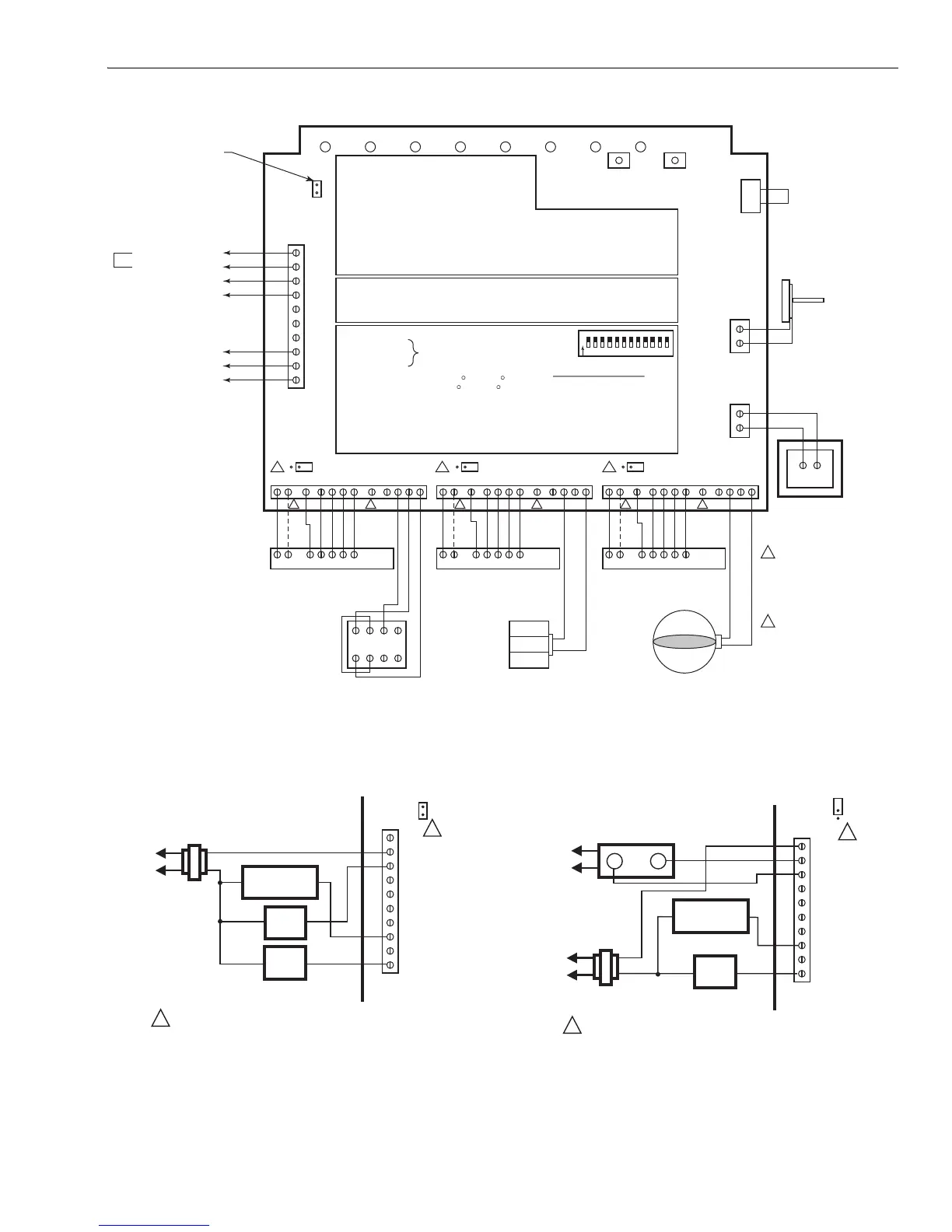

Fig. 13. EMM-3U System wiring diagram.

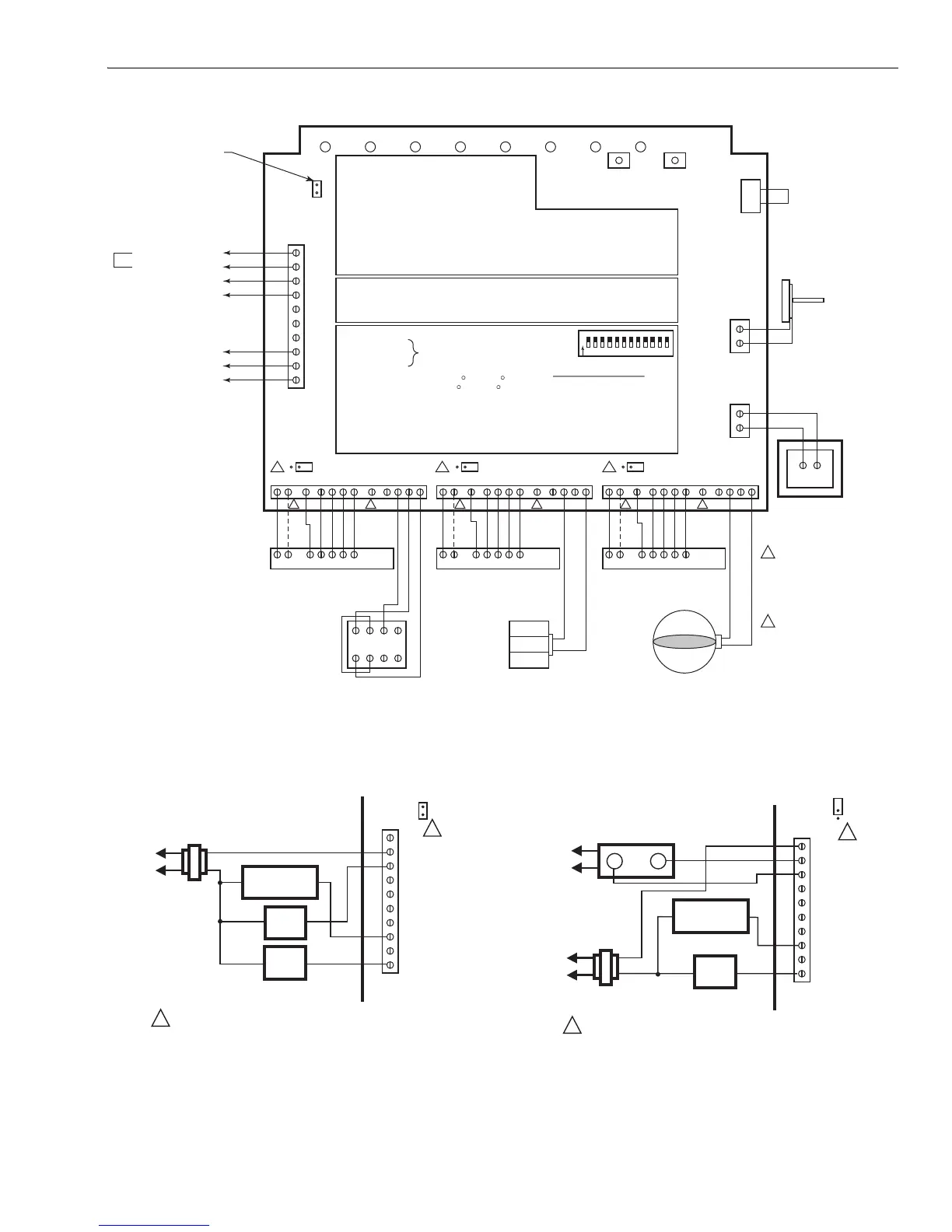

Fig. 14. Conventional single-stage single transformer

system wiring diagram.

Fig. 15. EMM-3U oil heating wiring diagram.

ZONE

THERMOSTATS

ZONE DAMPER MOTORS

M1 - common

M4 - power open

M6 - power closed

24 Volt Equipment

Transformer(s)

MOMENTARY PUSHBUTTON SWITCHES:

BOOT USED TO CLEAR THE SYSTEM AND MICROPROCESSOR.

PURGE OVERRIDE USED TO BYPASS THE PURGE CYCLE WHILE TROUBLESHOOTING.

DIP SWITCH SETTINGS

1 STAGE TIMER

2 STAGE TIMER ON OFF

3 STAGE TIMER 1 0 TABLE

4 SYSTEM TYPE CONV HEAT PUMP

5 ZMS HIGH LIMIT 160 F 120 F

6 ZMS LOW LIMIT 40 F 48 F

7 HEAT FAN HVAC PANEL

8 PURGE FAN HVAC PANEL

9 PURGE DAMPER NO CHG OPEN

10 PURGE TIME 2.0 MIN 3.5 MIN

11 EM HEAT FAN HVAC PANEL

12 2ND STAGE EM HEAT YES NO

SEE

TABLE

#1 #2 #3 TIME

1 1 1 5 MIN

1 1 0 10 MIN

1 0 1 15 MIN

1 0 0 20 MIN

0 1 1 30 MIN

0 1 0 45 MIN

0 0 1 60 MIN

0 0 0 NO TIMER

LED STATES:

RED HEAT LED HEATING MODE

GREEN COOL LED COOLING MODE

YELLOW PURGE LED PURGE MODE

GREEN FAN LED FAN MODE

RED EM HEAT LED EM HEAT MODE

FLASHING RED HEAT LED ZMS SENSOR EXCEEDS HIGH LIMIT IN HEATING

FLASHING GREEN COOL LED ZMS SENSOR EXCEEDS LOW LIMIT IN COOLING

FLASHING YELLOW PURGE LED

NO ZMS SENSOR INSTALLED OR ZMS SENSOR FAILUR

E

ZONE LEDS

ON (GREEN COLOR) DAMPER IS OPEN OR OPENING

OFF (NO COLOR) DAMPER IS CLOSED OR CLOSING

R

C

R

H

W

1

W

2

E

BOOT PURGE

OVERRIDE

Single Transformer

Heating/Cooling

systems require a

jumper to be installed

connecting R

H

and R

C

(factory installed).

1 C terminal

connection is not

required on battery

powered, power

stealing, or some

electromechanical

thermostats.

2 Leave jumper

disconnected for

conventional

thermostats.

Discharge Air

Temperature

Sensor

(See C7735

Installation

Instructions

for further

information.)

R

C

DATS

DATS

OFF

ON

EM

HEAT

B

O

Y

1

Y

2

G

Cooling Transformer

Heating Transformer

First Stage Heat Relay

econd Stage Heat Relay

First Stage Cool Relay

Second Stage Cool Relay

Fan Relay

his diagram shows the typical

wo-stage equipment, thermostat,

nd damper motor connections.

or specific wiring for other

hermostats, damper motors, and

VAC Equipment, refer to the

nstallation Instructions.

456Z

123X

Power-open

Power-closed

(Opposed Blade

Damper Motors)

G W2Y2 M6M4M1

G

Y1

Y1W1

C

R

R

CW2Y2

L

1

Zone 1 Thermostat

ZONE 3

G W2Y2 M6M4M1

G

Y1

Y1W1

C

R

R

CW2Y2

L

Zone 2 Thermostat

ZONE 2

G W2Y2 M6M4M1

G

Y1

Y1W1

C

R

R

CW2Y2

L

Zone 3 Thermostat

ZONE 1

CR

Power-closed

Spring-open

(Model ZD)

Power-closed

Spring-open

(Model ARD)

24 Volt 40VA

Transformer

24V AC

40VA

R

C

/R

H

JUMPER

ZONE PANEL

TRANSFORMER

HEAT COOL PURGE FAN EM. HEAT ZONE 1 ZONE 2 ZONE 3

EQUIPMENT

1

O

N

2 3 4 5 6 7 8 9 101112

222

1 12 2 2

O/BW1/E O/BW1/E O/BW1/E

TRANSFORMER

HEAT

RELAY

1

HOT)

2

COOLING

CONTACTOR

FAN

RELAY

LEAVE FACTORY INSTALLED R

H

TO R

C

JUMPER IN PLACE

FOR SINGLE TRANSFORMER SYSTEM.

1

R

C

R

H

W

1

W

2

E

B

O

Y

1

Y

2

G

PANEL

1

T T

24V

OIL PRIMARY

FAN

RELAY

COOLING

CONTACTOR

REMOVE FACTORY INSTALLED R

H

TO R

C

JUMPER.

1

1

L1

(HOT)

L2

L1

(HOT)

L2

R

C

R

H

W

1

W

2

E

B

O

Y

1

Y

2

G

PANEL

Loading...

Loading...