N200-102-00 3 I56-3947-200

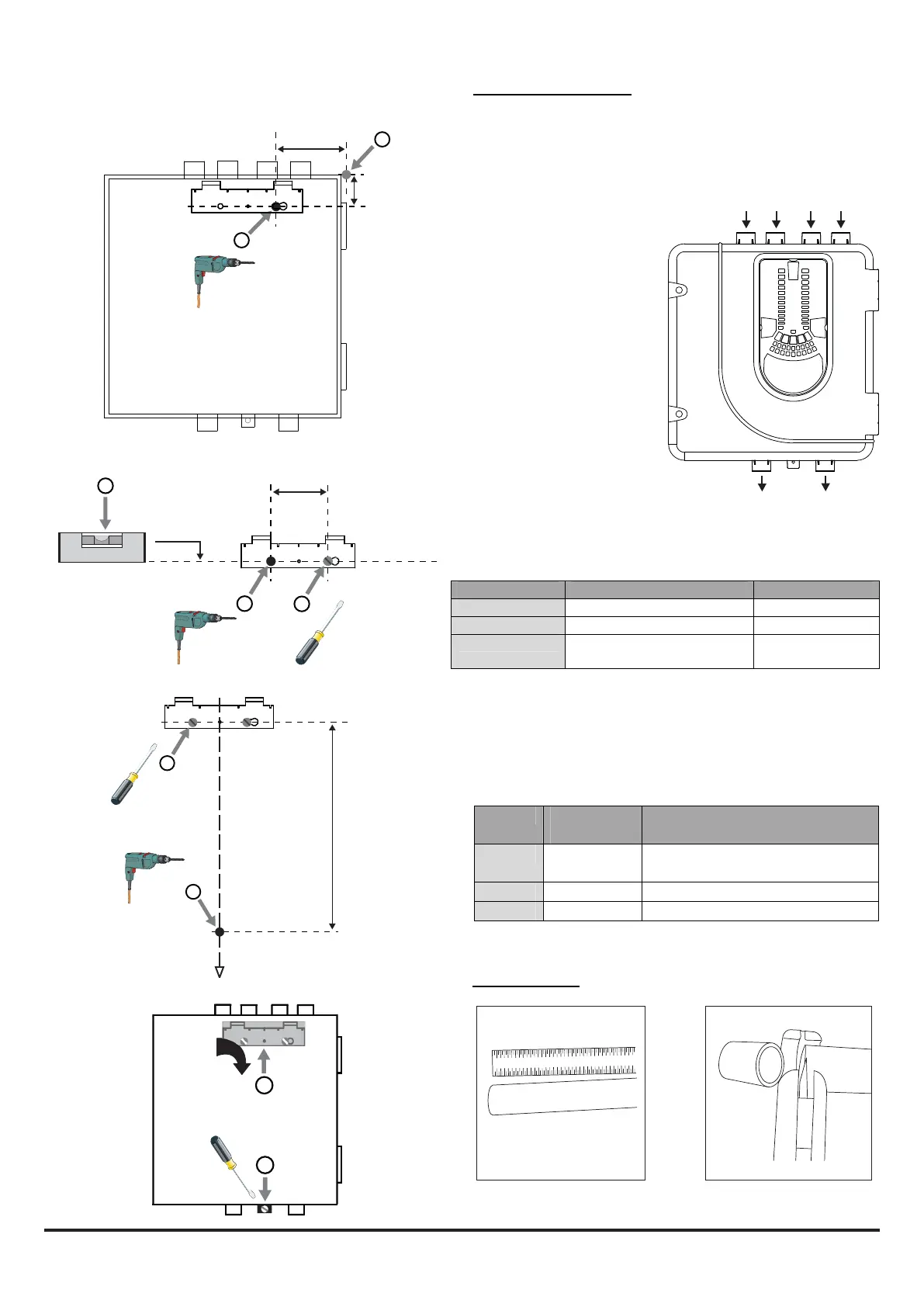

Figure 7: Sequence (1 to 9) to Mount the Detector on the Bracket

Pipe Installation

1 2 3 4 5 6 7 8 9 10 1112 13 14 15 16

17 18

1 2 3 4 5 6 7 8 9 10 1112 13 14 15 16 17 18

99 mm

41

1

2

mm

90 mm

4

3

0.00

o

5

329 mm

6

7

7a

7b

7c

7d

8

9

1 2

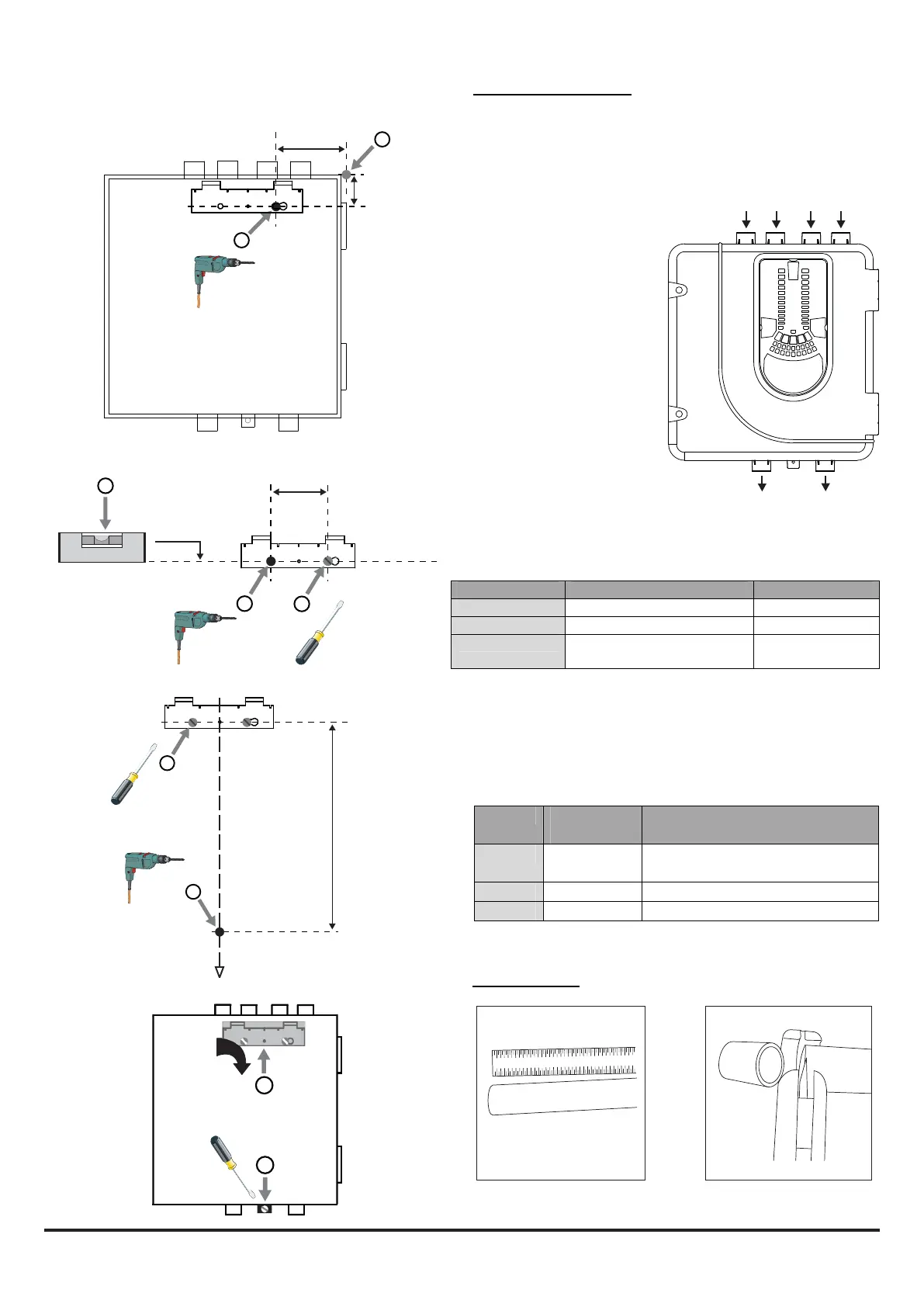

FAASTLTMODEL INLETPIPEHOLE OUTLETPIPEHOLE

NFXI‐ASD11 1&2,or1or2 5

NFXI‐ASD12 1&2,or1or2 6

NFXI‐ASD22 Channel1‐1&2,or1or2

Channel2–3&4,or3or4

5

6

Pipe Hole Conguration

Figure 8 below shows the pipe holes available on the unit. Each

unit has 2 pipe holes per channel (so if installing a 1 channel unit,

holes 3 and 4 do not function). Use Table 1 to locate the holes

required for the installation:

Figure 8: Pipe Holes

Table 1: Pipe Holes Used for Each FAAST LT Model

Note 1: Pipe holes not used should be kept sealed.

Note 2: Do NOT glue pipes into the pipe holes.

Table 1a: Maximum Number of Pipe Holes Allowed Per Channel

for EN54-20 Compliance

All gures quoted using highest (level 1) sensitivity.

1

2

3

4

5

6

CLASS PIPELENGTH

(m)

MAXNUMBEROFHOLESPER

CHANNEL

C 100 18(10x2.5mm,8x3mm) +3mm

nonsensingendhole)

B 100 6 (4x4mm,2x5mmincendhole)

A 80 3(1x5mm,2x6mmincendhole)

Loading...

Loading...