ID50 Series Panel - Installation, Commissioning & Configuration Manual

Appendix 2 - ID60 Panel Differences

A2 - 3

997-263-000-11, Issue 11

January 2010

VIEW

TM

sensors remain

inoperable for 60 seconds

after being replaced

while calibrating

VIEW

TM

Co-operative Multi-sensing

Co-operative sensing is carried out automatically between

VIEW

TM

sensors in the same group and across sensor

type. Grouped sensors co-operate within the group

providing greater levels of sensitivity with a reduced risk

of false alarms. When first installed, VIEW

TM

sensors are

all allocated to group 1 but they can be configured in up

to 50 groups. Sensors allocated to group ‘0’ operate

independently. An example of VIEW

TM

sensor co-

operative grouping is given below:

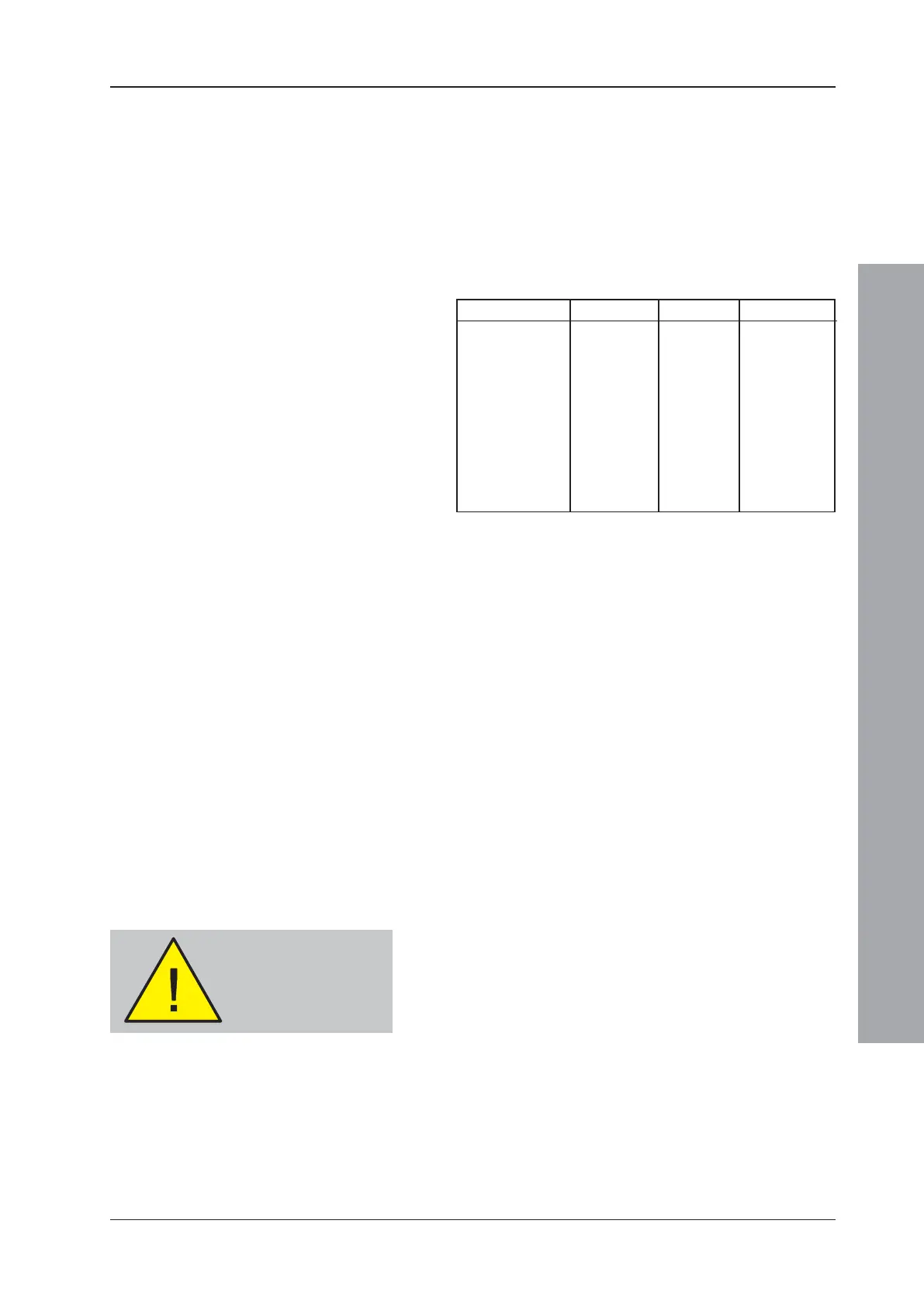

Address Type Zone Group

03 AVS 1 01

04 AVS 1 02

05 AVS 1 02

09 AVR 1 01

10 AVS 1 02

11 AVS 1 00

15 AVS 2 01

16 AVS 2 01

17 AVS 2 02

27 AVS 2 01

Each group can have one or more VIEW

TM

sensors

configured as reference sensors (AVR). Sensors placed

such that external smoke influences (eg. bonfires and

exhaust fumes) can be detected early should be

configured as AVRs. When these influences are detected

by the AVR the group can then be temporarily desensitised.

VIEW

TM

Sensor Sensitivity

Most local codes of practice require very low levels of alarm

sensitivity selection be tested on-site before implementation.

Alarm sensitivity level 6 (L6) and below generally require

a 90-day test to ensure the sensor environment is suitable

for a higher sensitivity setting. This is not required for

high levels of pre-alarm sensitivity selection.

Dynamic Intelligent Grouping (DIG) Operation

The Dynamic Intelligent Grouping (DIG) Operation only

performs calculations on up to five sensors with the highest

value. This is an advantage in a group of many sensors, as

any condition will quickly be recognised by the panel.

A2.1 Calibrating VIEW

TM

Sensors

Each VIEW

TM

sensor is automatically calibrated on first

operation with the panel. This calibration is completed at

one of the following times:

a. Approximately 90 secs after the panel is powered on.

b. 60 secs after the sensor is installed on a panel which

is already operating normally.

During this initial period (which is required to allow the

VIEW

TM

sensor to stabilise) the sensor must not be

exposed to smoke or other abnormal conditions,

otherwise the panel may report a sensor fault.

If a VIEW

TM

sensor is removed from the operational loop,

or communication with the panel is broken for a minimum

of 30 secs, recalibration will take place automatically.

Note: If a VIEW

TM

sensor is removed and cleaned, or

replaced with a new one, wait at least 30 secs after

removal before replacing it.

Loading...

Loading...