39

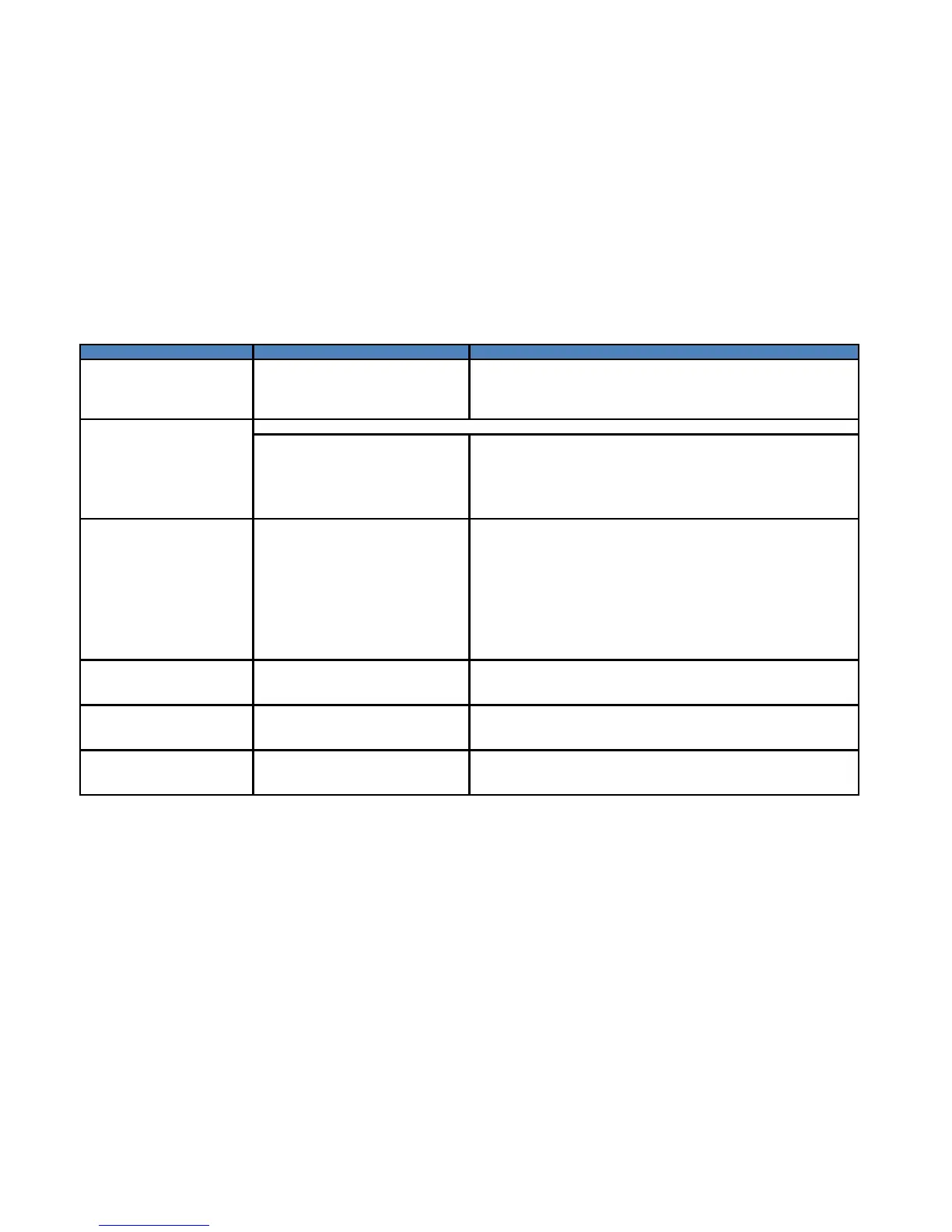

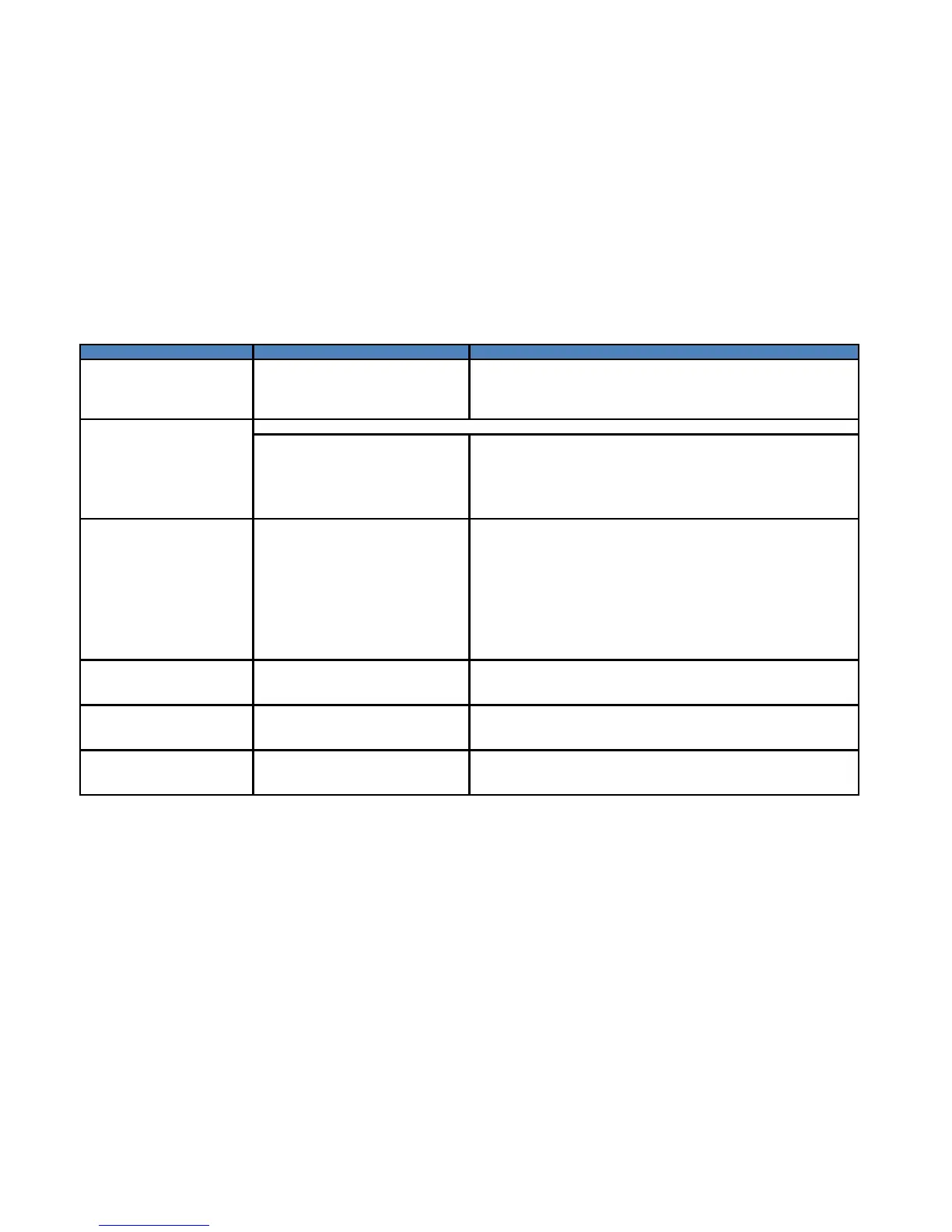

Problem PossibleCause PossibleSolution

IceBladeisfrozenin‐place

1. MotorOverloadsettingistoohigh. 1. AdjusttheMotorOverloadsettingattheControlModule(CM).

2. Iceisfreezingtoothickortoohard. 2. AdjustrefrigerationtoIceFlaker.

3. DriveMotorhasstopped. 3. See“DriveMotorwillnotstart”above.

4. FlexCouplingisbroken. 4. CheckandreplaceFlexCouplingasnecessary.

IceFlakernotmeetingrated

capacity

RunFieldCapacityCheckbeforemakinganyadjustments(seep.20).

1. IncorrectEvaporatorTemperature. 1. AdjustrefrigerationtoIceFlaker.

2. Supplywatertemperatureisoutside

mandatoryrange.

2. Adjustsupplywatertobetween45°Fand90°F.Fortemperaturesbelowrange,

contactHoweaboutLowTemperatureMixingValve.

3. Ambienttemperatureisoutsidemandatory

range.

3. Adjustambienttemperaturetobetween50°Fand100°F.Inunabletoadjust,

relocatetheIceFlaker.Fortemperaturesbelowrange,contactHoweaboutLow

AmbientKit.

Icefreezestogether

intheIceBin

1. WaterDistributionPanisoverflowing. 1. AdjustWaterRegulatingValvesotheWaterDistributionPanishalfwayfull.

2. WaterfromSideSpoutsorLeadSpoutis

notreachingfreezingsurfaceof

Evaporator.

2. Cleanspoutsofanydebrisorblockages.Makesureallspoutsareperpendicularto

andwithinreasonabledistancefromsurfaceofEvaporator.

3. Wateris“ramping”offringsoficeformed

onEvaporator.

3. AdjustrefrigerationtotheIceFlaker.

4. IceBinisnotdrainingproperly. 4. CheckthatalldrainsareflowingfreelyandpitchedawayfromIceBin.

5. IceturnoverislowandIceBininventory

hasbecomestaleandclumpedbylengthy

storagetime.

5. Useordiscardicewithinareasonabletimeofproducingit.ContactHoweabout

EnergySaverIceProductionManagementSystem.

CondensingUnitisin

LowSuctionPressurePumpDown

1. Lackofrefrigerant. 1. Checkforleaksandrepair.Addrefrigerant.

2. Insufficientwatersupply. 2. ReplaceWaterFilter.Checkforcloggedtubesorvalves.

3. Refrigerationlineblockage. 3. Checkfilterdrier,TXV,EPRandreplaceasnecessary.

CondensingUnitisoffon

LowOilPressureFailure

1. Lackofrefrigerant. 1. Checkforleaksandrepair.Addrefrigerant.

2. Refrigerantfloodback. 2. AdjustrefrigerationtoIceFlaker.

3. Improperpipingortraps. 3. Correctpiping.

CondensingUnitisoffon

HighDischargePressureFailure

1. Non‐condensablesinthesystem. 1. Removethenon‐condensables.

2. Systemisoverchargedwithrefrigerant. 2. Removeexcessrefrigerant.

3. Fanisnotrunning. 3. CheckFanCyclingControlandadjustasnecessary.

Loading...

Loading...