Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Function Introduction

HD3L Series Controller User Manual ―53―

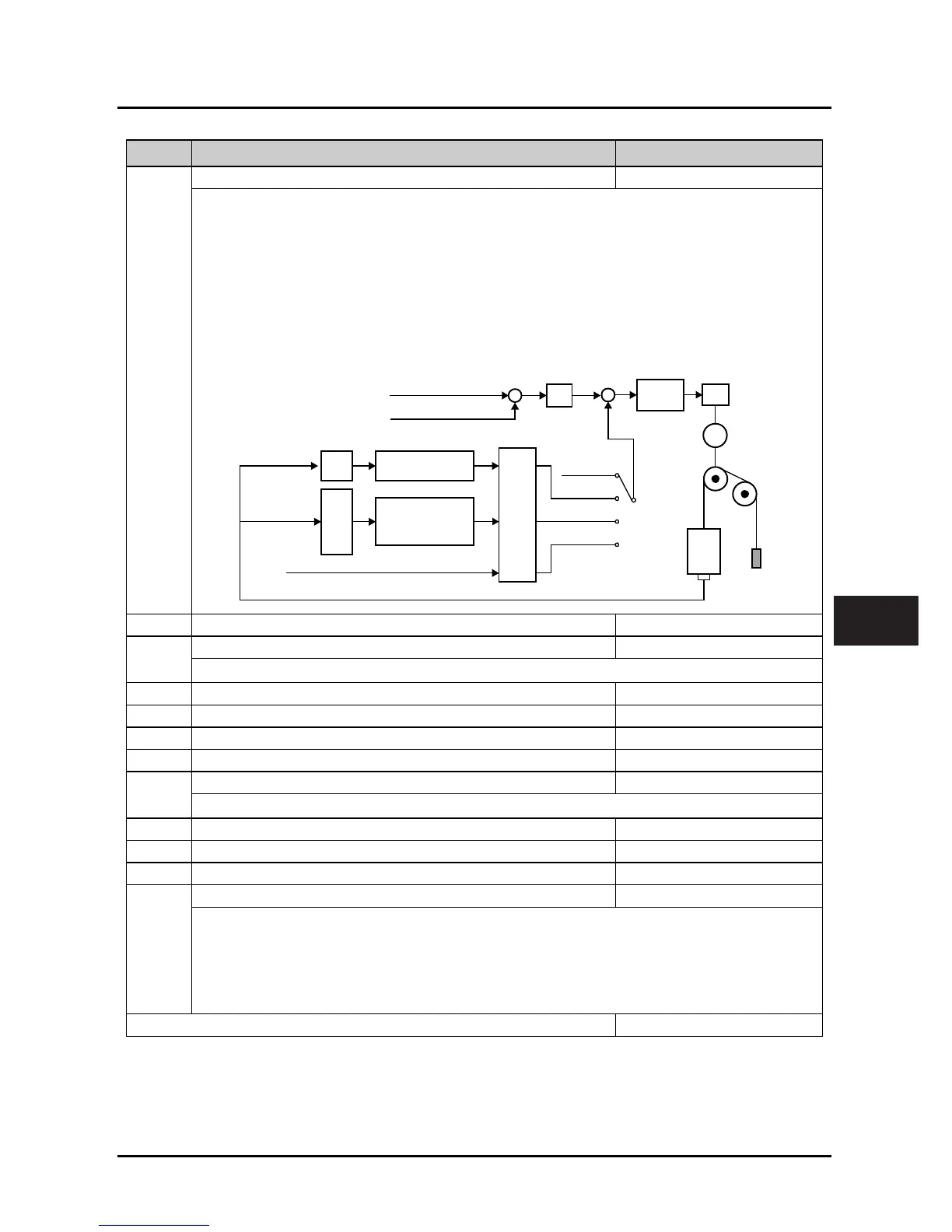

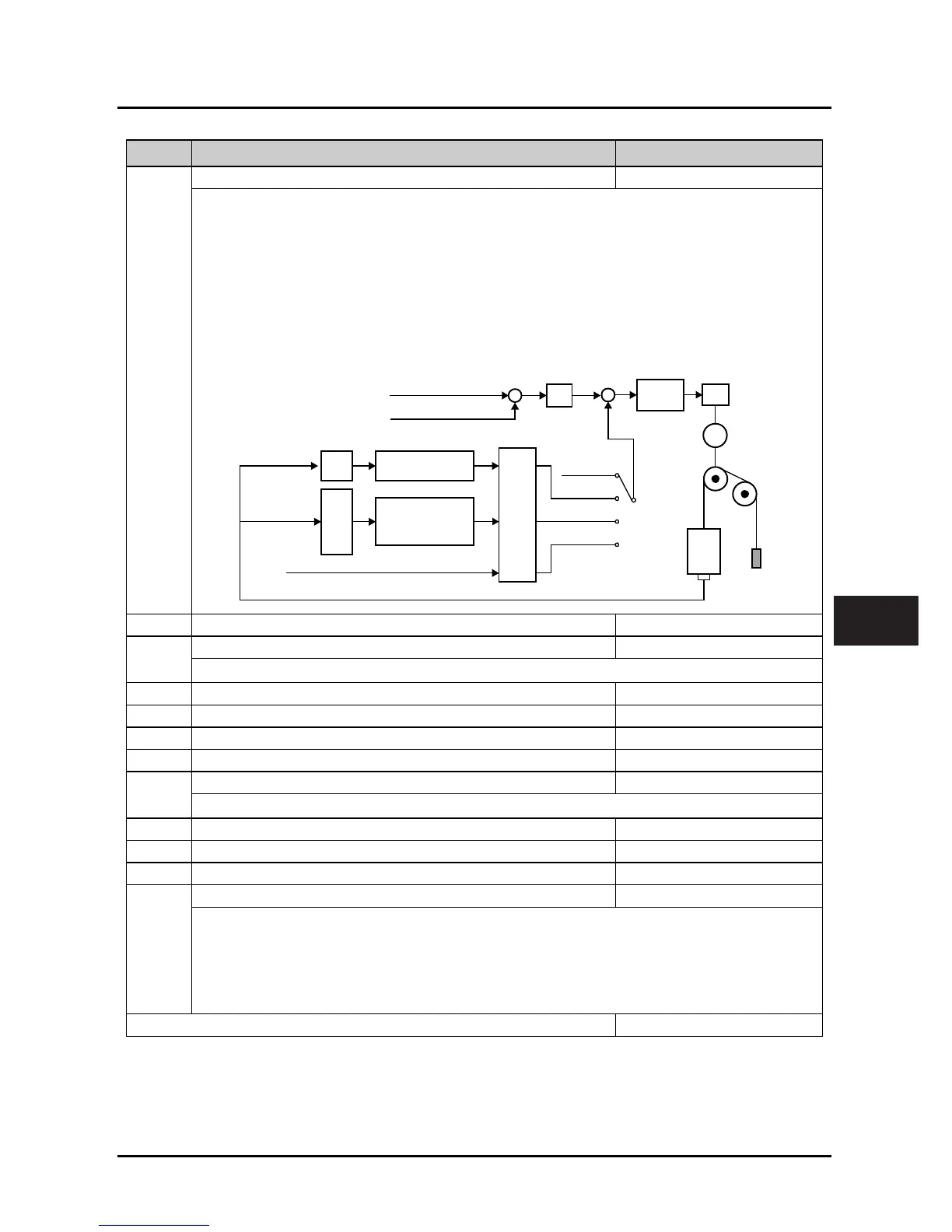

6.2.7 F06: Weighing Compensation Parameters

Ref. Code Function Description Setting Range [Default]

F06.00 Pre-torque selection 0 - 3 [0]

The pre-torque function can output the load balancing torque in advance to avoid reverse and reduce the

start impact.

0: No pre-torque function.

1: Analogue setting. Output balancing torque according to the input analogue weight signal.

2: DI setting. Output balancing torque according to the input digital weight signal.

3: Digital pre-torque. Select 3 if no weighing device is at the elevator.

• Then adjust the pre-torque digital setting parameter to make the elevator fully excitation before open

brake, therefore improve the starting comfort.

• Compensation value = Pre-torque bias - Pre-torque digital setting.

F06.01 Up pre-torque bias 0.0 - 100.0 [50.0%]

F06.02 Down pre-torque bias 0.0 - 100.0 [50.0%]

Pre-torque bias = (Elevator counter weight – Car weight) / Rated load.

F06.03 Up electrical pre-torque gain 0.000 - 9.000 [1.000]

F06.04 Up brake pre-torque gain 0.000 - 9.000 [1.000]

F06.05 Down electrical pre-torque gain 0.000 - 9.000 [1.000]

F06.06 Down brake pre-torque gain 0.000 - 9.000 [1.000]

F06.07 Pre-torque digital setting -100.0 - 100.0 [10.0%]

At no weighing device, set the pre-torque value by changing F06.07.

F06.08 DI weighing signal 1 0.0 - 100.0 [10.0%]

F06.09 DI weighing signal 2 0.0 - 100.0 [30.0%]

F06.10 DI weighing signal 3 0.0 - 100.0 [70.0%]

F06.11 DI weighing signal 4 0.0 - 100.0 [90.0%]

When digital weighing signal termianl input is enabled, its value is the percentage of rated load.

For example:

• If DI weighing signal 1 is enabled, it expresses that the present load is F06.08% of the rated load.

• If numbers of terminals are enabled simultaneously, the max. number terminal will be considered as the

valid one.

F06.12 - F06.20 Unused

Speed command

Speed feedback

M

Car

Counte

Loading...

Loading...