MAINTENANCE AND PARTS

0

powermax1000 Operator Manual 5-3

Inspect Consumables

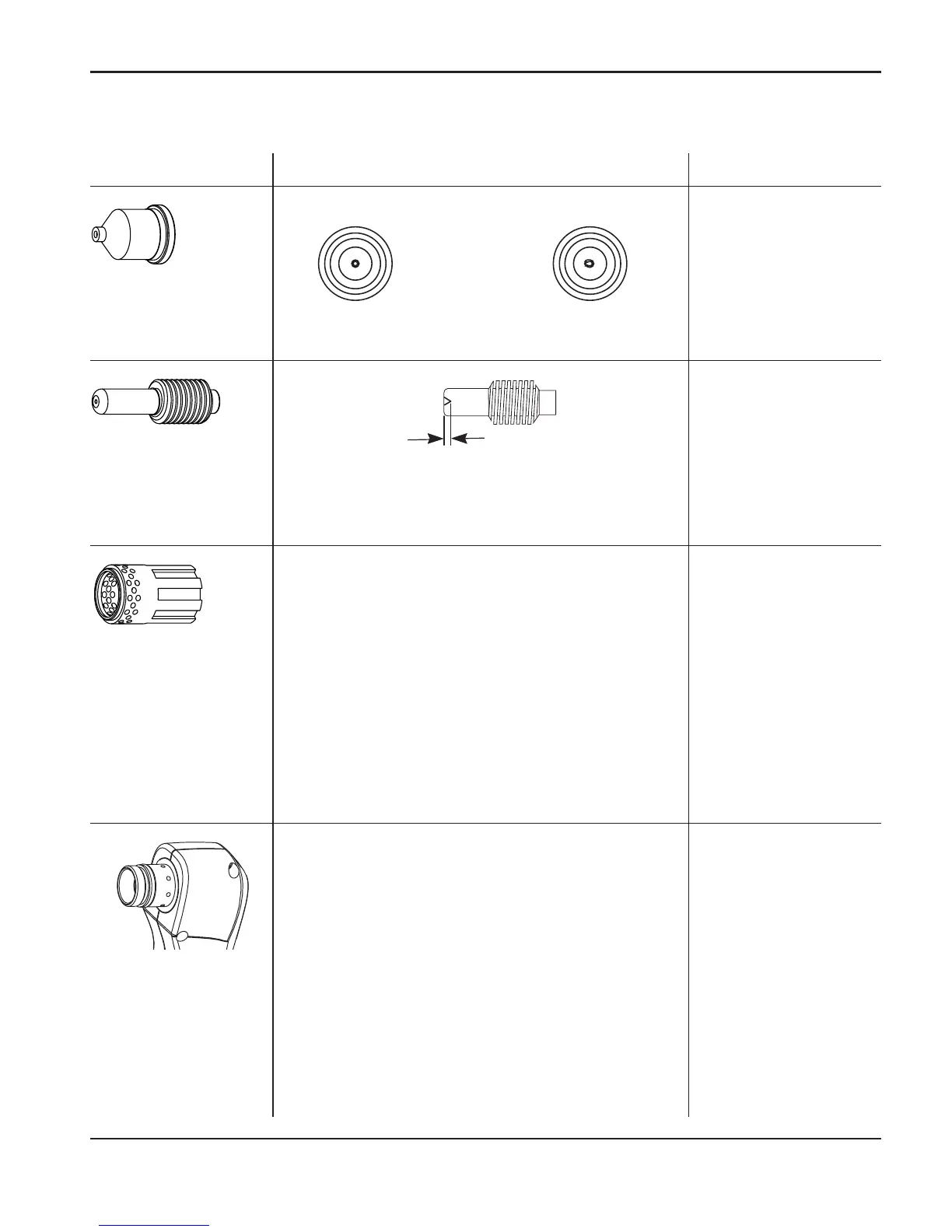

Nozzle

Center hole Good Worn Replace

Roundness of through hole

Center surface Maximum pit depth Replace

1/32 inch (0.8 mm)

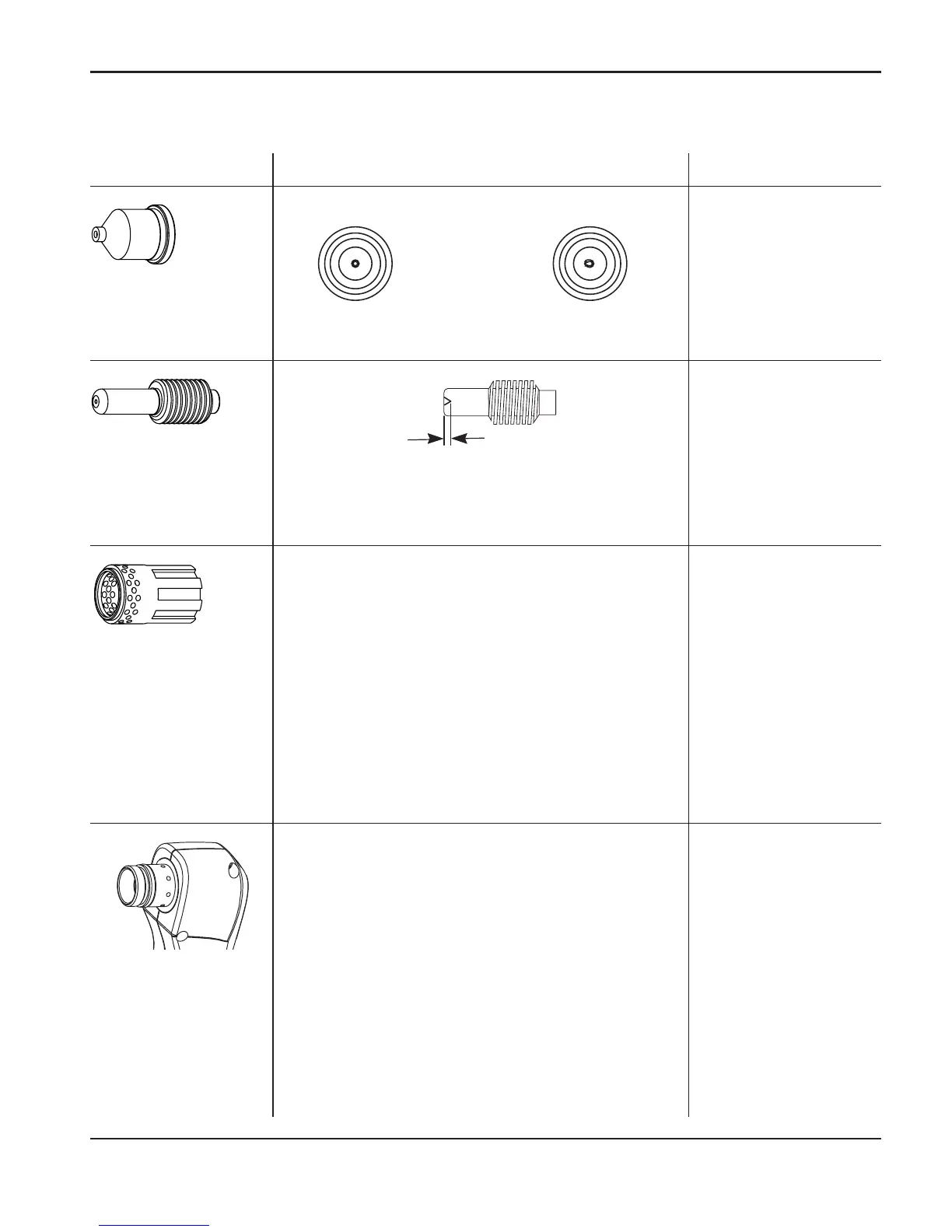

Electrode

Part Check For Action

External surfaces Damage or debris Replace

Central bore (I.D.) Does electrode slide easily? Replace

Gas holes Blocked holes Replace

Swirl Ring

External surfaces Damage or wear Replace

Dry surface Apply a thin film of

Hypertherm grease

(Part No. 027055)

Torch O-ring

Max. 1/32 inch

(0.8 mm)

Loading...

Loading...