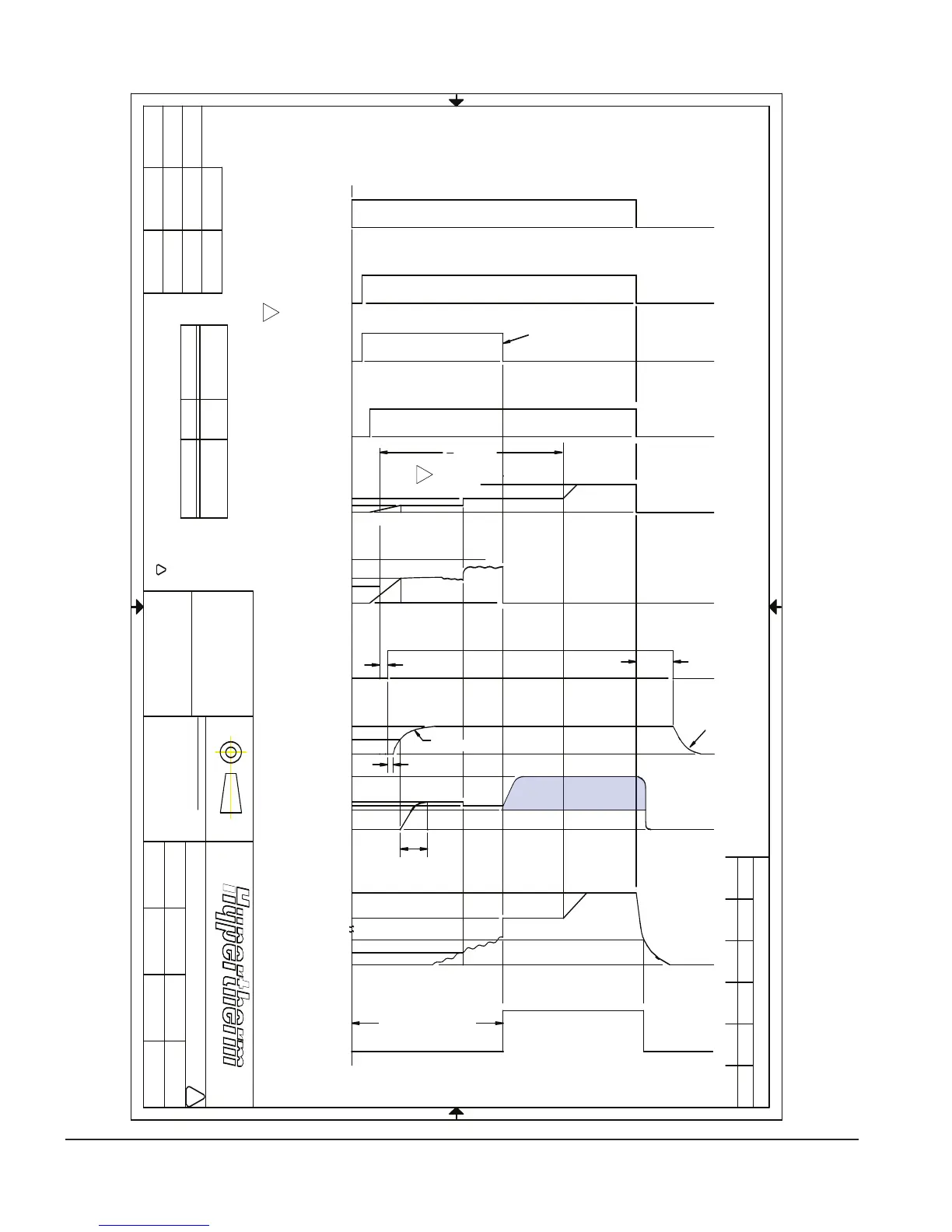

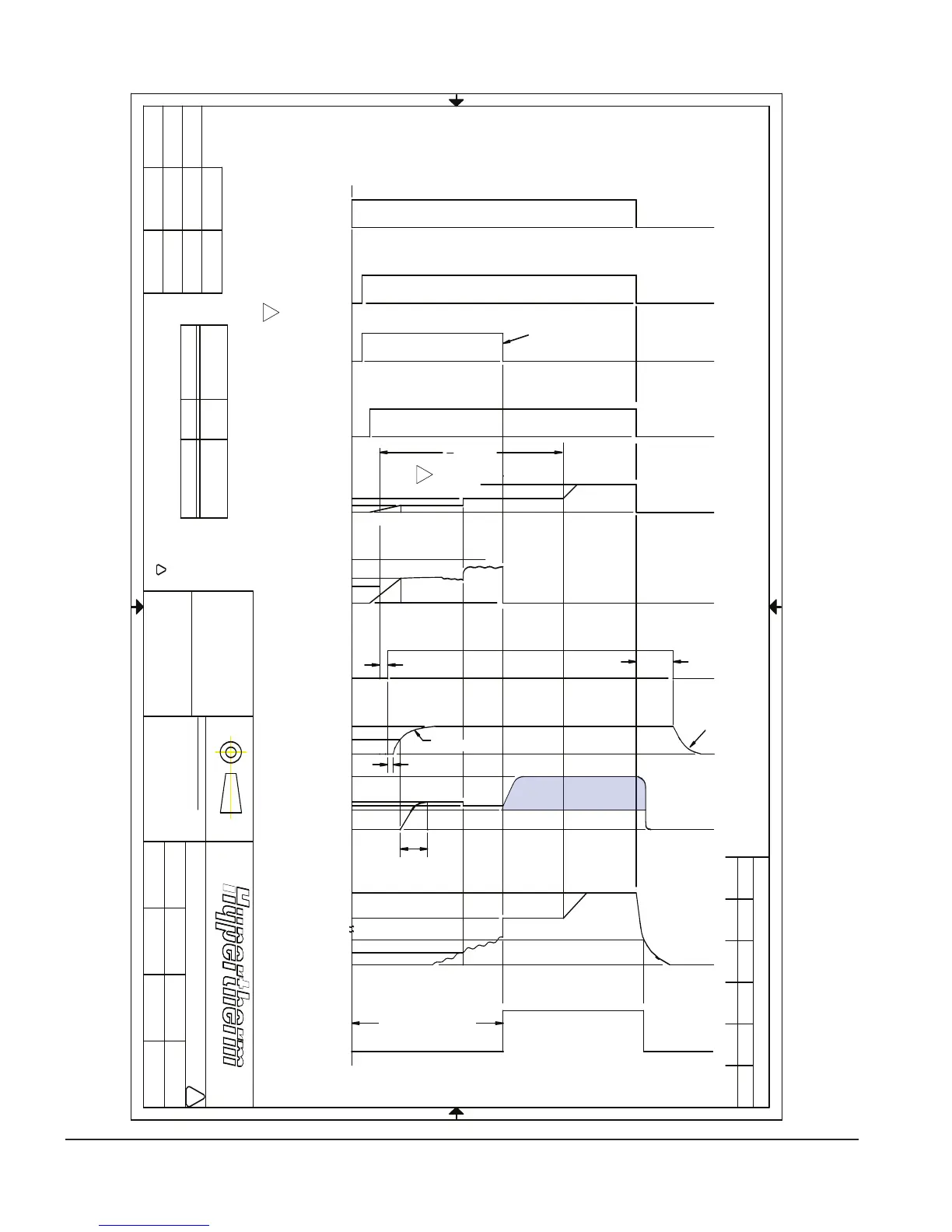

t=0

1

0

S

tart

t

Start

0

1

2ms

Debounced

A

rc

0

Pilot

1

2ms

D

igitized

X

FR signal

E

nable

Inverter

0

1

3ms

(

INV_EN

)

Icommand

0

25A

3

ms

Setpoint

8

0

1

6

12ms

Ipilot

(

Amps)

Gas

0

1

P

ostflow

60

Pcritical(15)

at Torch

(psi)

Gas Pressure

Time

x

Consumable

Re-Seat

0

225

Voltage

Arc

(volts)

~

~

10ms

typ

250

1.6

25

I Setpoint

0

(amps)

I Work Lead

10.0 sec

NORMAL MODE

1ms

2

5

150

210

0.4

16A

v

alid

3ms

tdelay

0

1

If > 5.0 sec

pilot arc time out

XFR signal

Digitized

in DSP and

Switch

Constant

Tor ch Lead

Length(feet)

50 50

tdelay

(msec)

Time Constant

(msec)

250

Machine Motion

1

2ms

1.75A/ms

1.75A/ms

1. 200ms DELAY IS FOR TORCH LEAD

PRESSURIZATION.

>

200 ms

1.

2. CURRENT (I) VALUES SHOWN FOR 80A UNIT.

I cut max

60A UNIT80A UNIT

80 60

I cut min 25 20

I pilot 16/25 14/20

REQUIREMENTS PER HYPERTHERM P/N 048266.

3. RoHS/WEEE COMPLIANT AND OTHER REGULATORY

D 15365 6-1-06 6-5-06

APPROVEDDATEDRAWNDATEECNREV

REVISIONS

DESCRIPTION

ITEM NO.

DRAWN BY

PURPOSES WITHOUT PERMISSION

FOR MANUFACTURING OR FABRICATION

FROM HYPERTHERM, INC.

THIS DRAWING AND ALL INFORMATION

PROPRIETAR Y AND MAY NOT BE USED

CONTAI NED THEREON IS CONSIDERED

MATERIAL

TOLERANCES ARE:

UNLESS OTHERWISE SPECIFIED:

2 PL DECIMAL ±.01

FRACTIONS ±1/64

ANGULAR ±2∞

DIMENSIONS ARE IN INCHES.

3 PL DECIMAL ±.005

PAR T MUST BE FREE OF BURRS AND SHARP

EDGES. BREAK SHARP EDGES IF NECESSARY

WITH CHAMFER OR RADIUS .015 MAX.

013341 013341B1

ELEC SCHEM:PMX1250 60/80A TMG

NTS 1 OF 2

3-9-01

Box-5010 Hanover, NH 03755-5010 603/643-3441

DATE

FILE NAME

DATEAPPROVED BY

SCALE SHEET

D

D

Loading...

Loading...