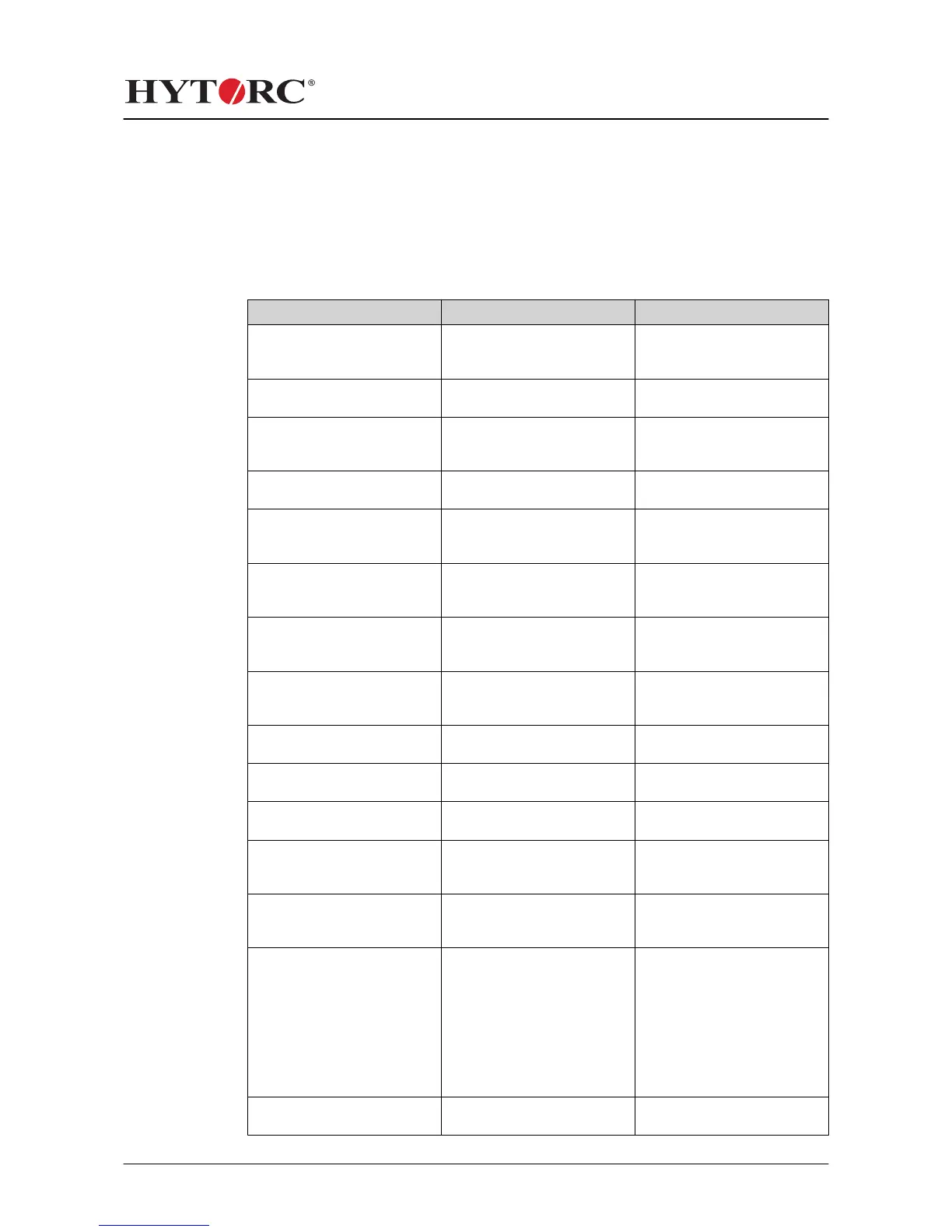

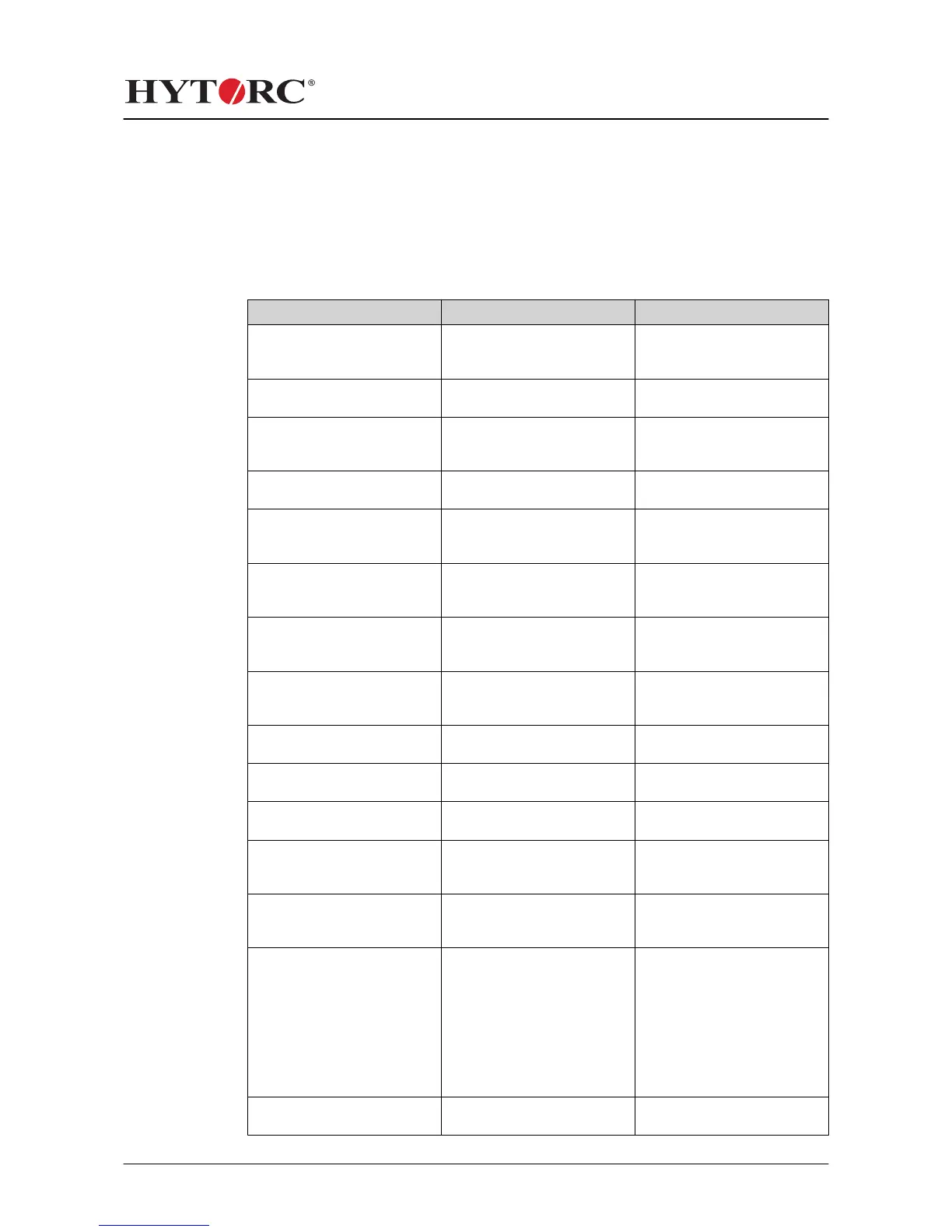

9 Troubleshooting

Try to find a solution for the problem using the tables. If you cannot find a solution for the

problem, contact your local HYTORC representative.

9.1 Tools

Problem Possible cause Solution

The tool does not move. The hose couplings on the tool

and the pump unit are not se-

cured properly.

Securely tighten the female

coupling to the male coupling.

The tool stalls. The reaction pawl was not acti-

vated.

See

Disengagement button for

reaction pawl

on page 27.

The piston in the tool does not

retract.

The hose couplings on the tool

and the pump unit are not se-

cured properly.

Securely tighten the female

coupling to the male coupling.

The linkage between the piston

and the drive arms is damaged.

Replace the defective part.

The pressure in the system

does not increase.

There is oil leakage due to a

defective piston, piston seal or

O-ring.

Replace the defective part.

There is leakage in the pres-

sure relief valve and/or the two

oil line connections.

Tighten the leaking connection.

Use a 9/16” open-end wrench.

A motor coupling is worn. The

pump makes sounds like peb-

bles in a tin can.

Replace the motor coupling.

The air shut-off valve fails due

to excessive moisture and/or

dirt in the air supply.

Clean the air shut-off valve and

the air lines.

The valve in the remote control

fails.

Replace the valve in the remote

control.

The tool leaks externally. Blind plugs or end caps are

worn/damaged or not secured.

Replace the blind plugs and/or

the end caps.

The O-ring or the gland seal in

the piston is defective.

Replace the defective part.

The tool operates backwards. An even number of hoses has

been connected.

Connect an odd number of ho-

ses. See

Hydraulic hose con-

nections

on page 19.

The male coupling and the fe-

male coupling have been inter-

changed.

Use a HYTORC twin hose.

The tool moves slower than

usual.

There is a leakage in the sys-

tem.

Adjust the pump pressure to

700 bar (10,000 psi) and switch

off the pump unit while holding

the start button. The pump

pressure must decrease to 100

bar (1,450 psi). If the pump

pressure decreases to 0 bar (0

psi), contact your local HY-

TORC representative.

The ratchet returns with a

stroke.

The square drive is defective. Replace the defective part.

Troubleshooting

37 - 001 - 35

Loading...

Loading...