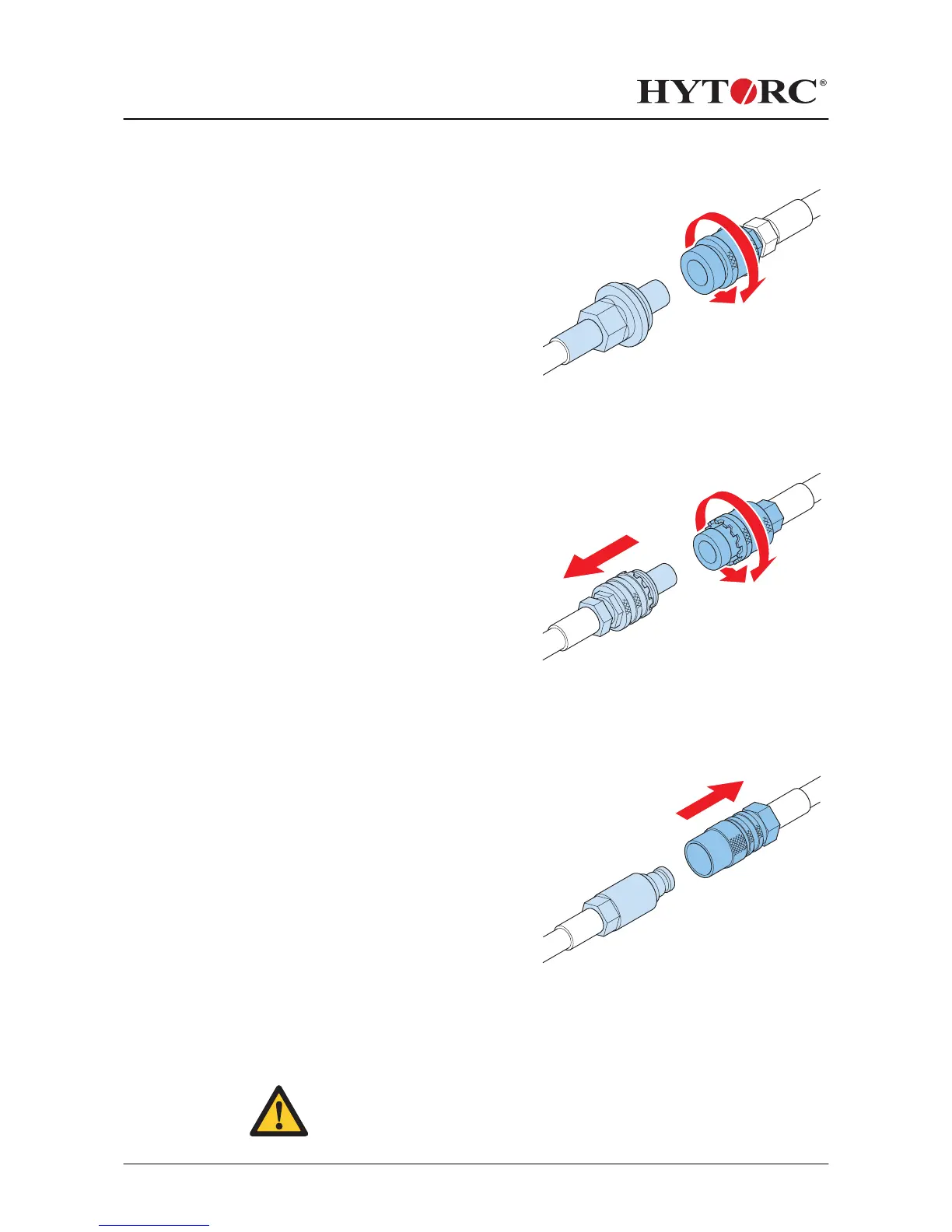

Screw-type safety couplings (Pioneer)

• To tighten the couplings (A), make sure that

the system is depressurized. Push the cou-

plings completely together to full engage-

ment, and tighten the locking ring of the fe-

male coupling to the male coupling. If the

couplings are not fully tightened, the tool will

not operate.

• To loosen the couplings (B), make sure that

the system is depressurized. Loosen the

locking ring of the female coupling from the

male coupling and pull the couplings apart.

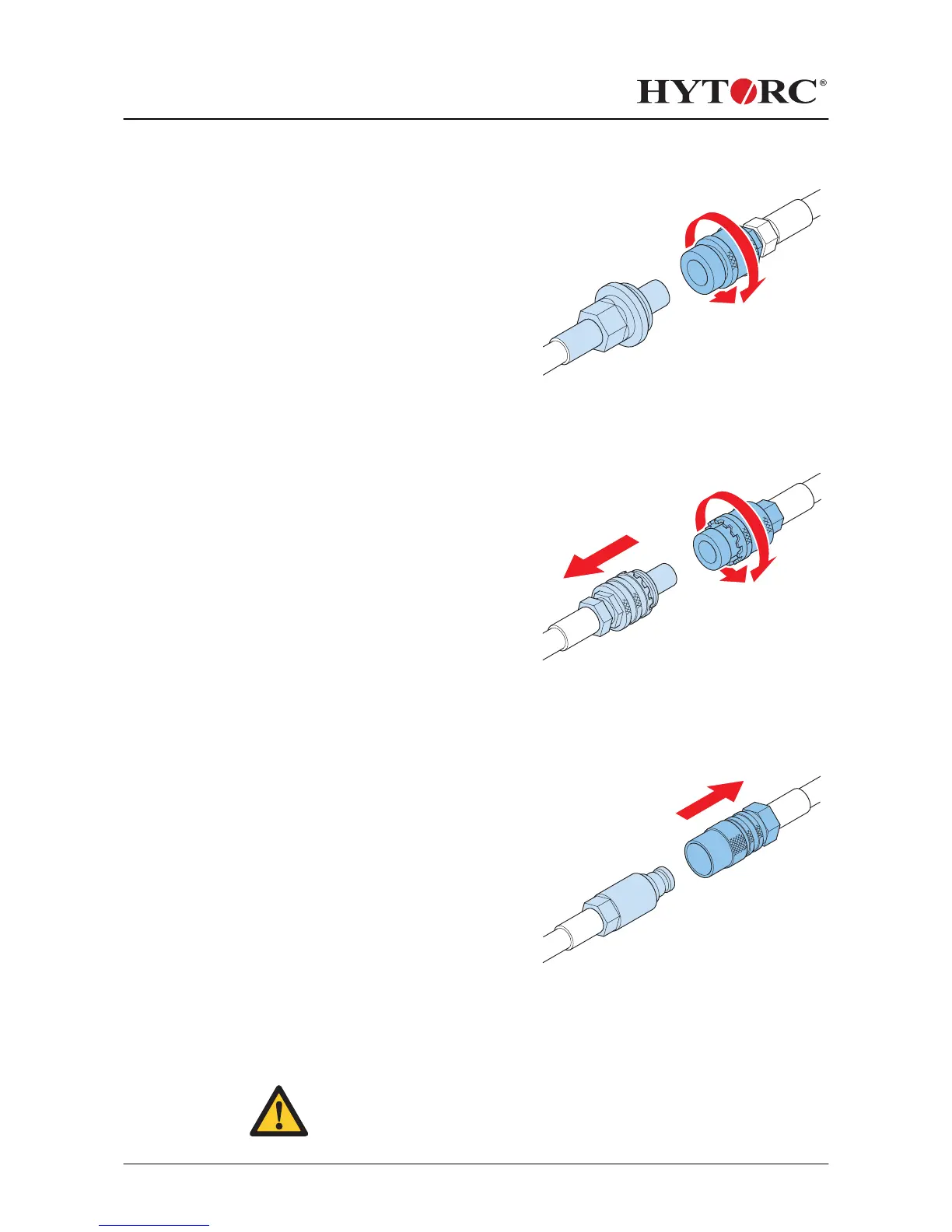

Toothed screw-type safety couplings (HYTORC

716)

The coupling is identical to the screw-type safe-

ty couplings (type Pioneer), but both coupling

are toothed. The male coupling has a toothed

locking ring which is axially displaceable. The

female coupling also has a toothed ring.

• To tighten the couplings (A), make sure that

the system is depressurized. Push the cou-

plings together and engage the teeth of male

coupling and the female coupling. If the cou-

plings are not fully tightened, the tool will not

operate.

• To loosen the couplings (B), make sure that

the system is depressurized. Pulll the tooth-

ed locking ring axially and loosen the locking

ring.

Quick couplings (HYTORC 1008)

• To tighten the couplings (A), make sure that

the system is depressurized. Pull back the

pull-back ring on the female coupling, push

the male coupling into the female coupling

and release the pull-back ring. Screw the

locking ring on the female coupling against

the pull-back ring.

• To loosen the couplings (B), make sure that

the system is depressurized. Screw the lock-

ing ring on the female coupling from the pull-

back ring. Pull back the pull-back ring to re-

move the male coupling from the female

coupling.

4.1.2 Connecting the hydraulic hoses

Warning:

• Make sure that the system is depressurized.

Installation

20 37 - 001 -

Loading...

Loading...