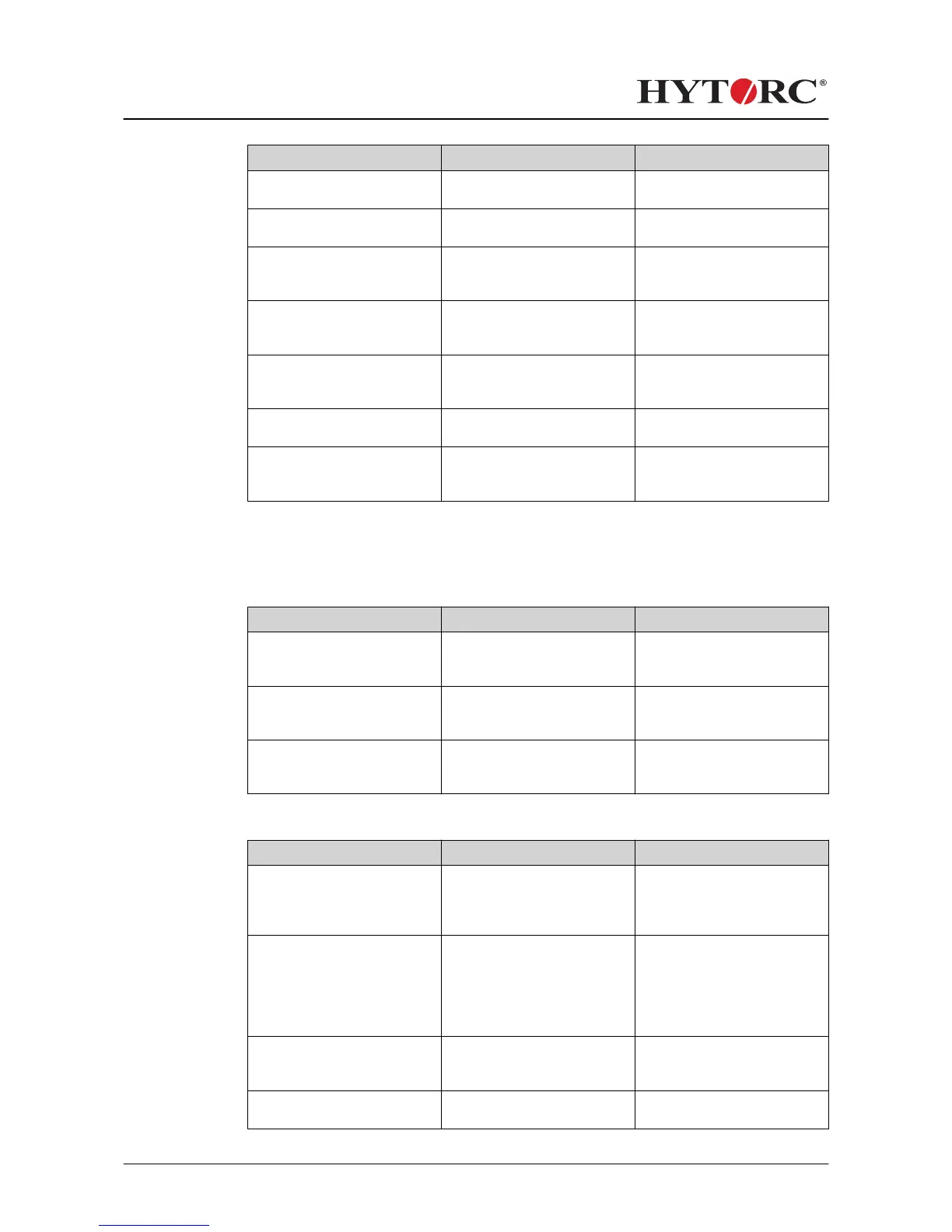

Problem Possible cause Solution

The ratchet does not take suc-

cessive strokes.

The square drive or the ratchet

spring is defective.

Replace the defective part.

The piston does not fully re-

tract.

Allow the piston to fully retract.

Cycle freely for several strokes.

If the problem persists, check

the reaction pawl.

The linkage between the piston

rod and the drive plates is dam-

aged.

Replace the defective part.

The tool locks onto the nut. The square drive is loaded at

full torque.

Use the disengagement lever

to remove the tool from the nut

or the bolt.

The tool operates backwards. Push the start button to release

the tool.

The tool cannot move freely

from surrounding objects.

Use the disengagement lever

to remove the tool from the nut

or the bolt.

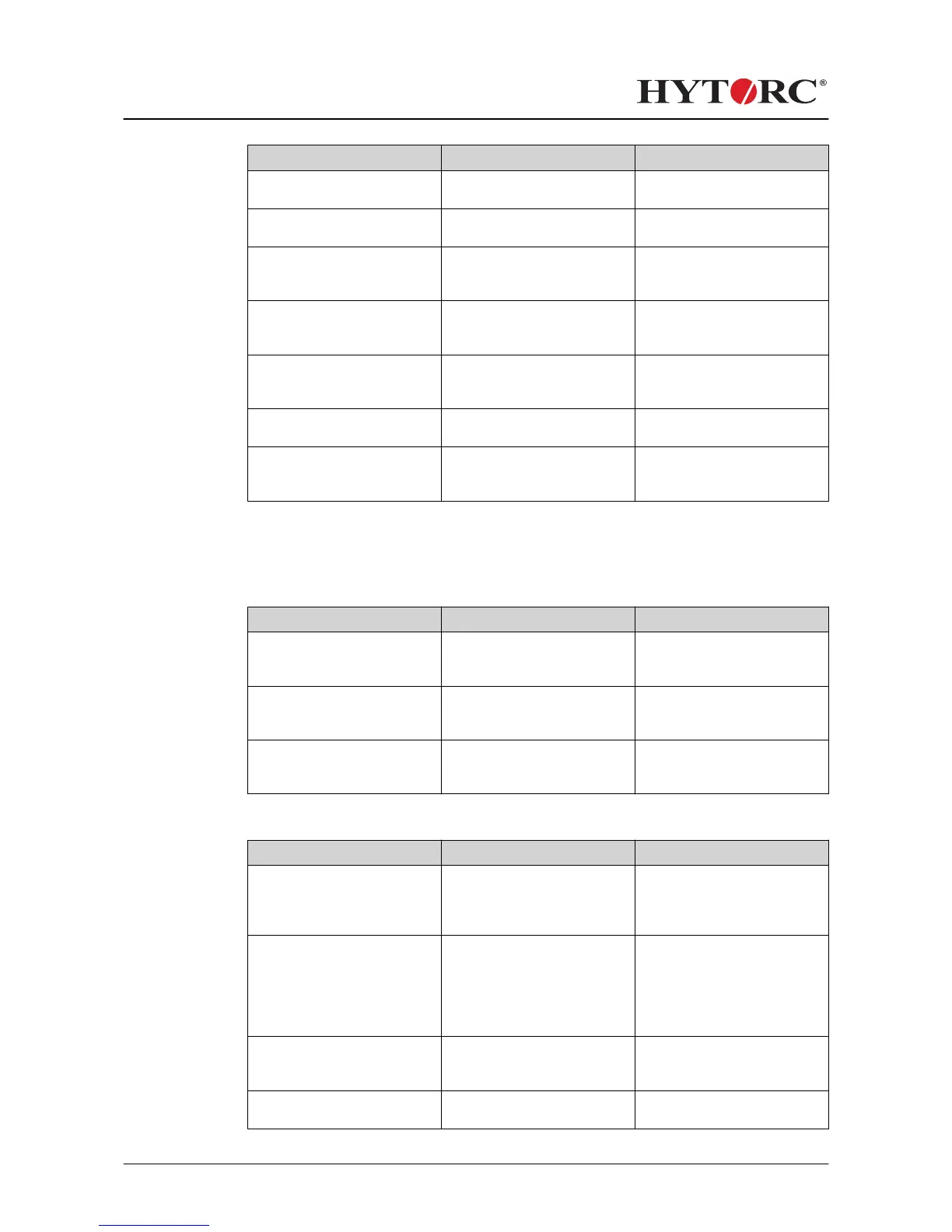

9.2 Pump units

9.2.1 General

Problem

Possible cause Solution

The pump pressure is not re-

peatedly accurate with a fixed

setting.

The pressure control valve is

dirty or defective.

Contact your local HYTORC

representative.

The pump unit operates and

provides pressure, but the tool

does not move.

The hose couplings on the tool

and the pump unit are not se-

cured properly.

Securely tighten the female

coupling to the male coupling.

The pressure in the system

does not increase.

A motor coupling is worn. The

pump makes sounds like peb-

bles in a tin can.

Replace the motor coupling.

9.2.2 Electric pump units

Problem

Possible cause Solution

The motor makes strange

noises and does not provide

pressure (400V pump units on-

ly).

The direction of rotation is in-

correct.

Change the direction of rota-

tion. See

Connecting the power

supply (400V)

on page 22.

The motor does not accelerate

and stops after starting.

There is drop in voltage due to

too thin or too long an exten-

sion cable.

Check the pump unit with the

mains plug directly in the wall

socket. Do not use an exten-

sion cable. See

Power supply

(electric pump units)

on page

22.

The motor operates, but the

tool does not make a complete

stroke.

The remote control cable is

damaged.

Contact your local HYTORC

representative.

The valve block is defective. Contact your local HYTORC

representative.

Troubleshooting

36 37 - 001 -

Loading...

Loading...