Hyundai Elevator Co., Ltd. STVF7 SYSTEM

REV.0 2009.11.06

TITLE

File Name :

STVF7 ADJUST MANUAL

STVF7 SERIES

ADJUSTMENT MANUAL

Document Number :

Rev. Commemts :

HELCO-C5-003-01 - 25 - A4(210㎜×297㎜)

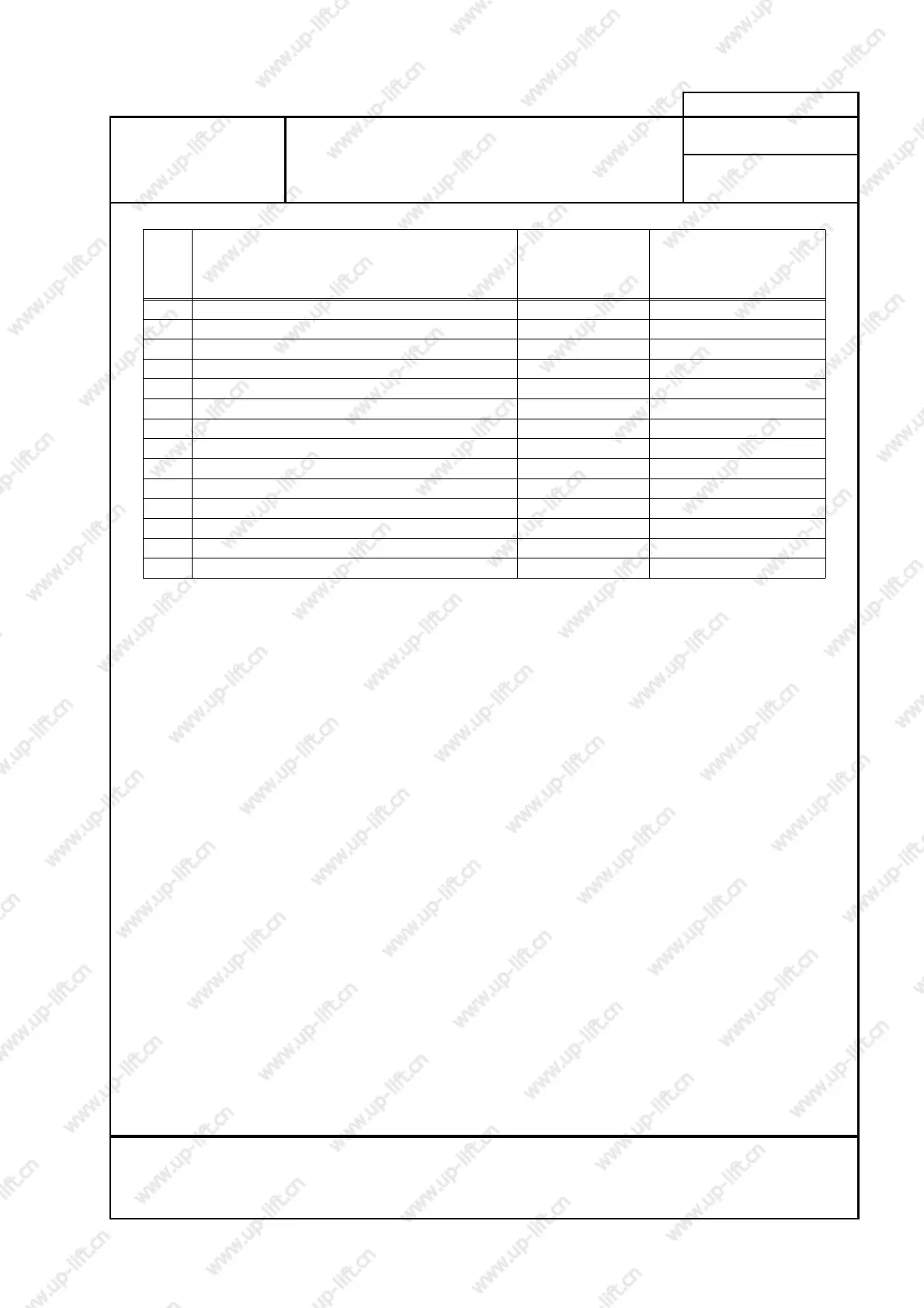

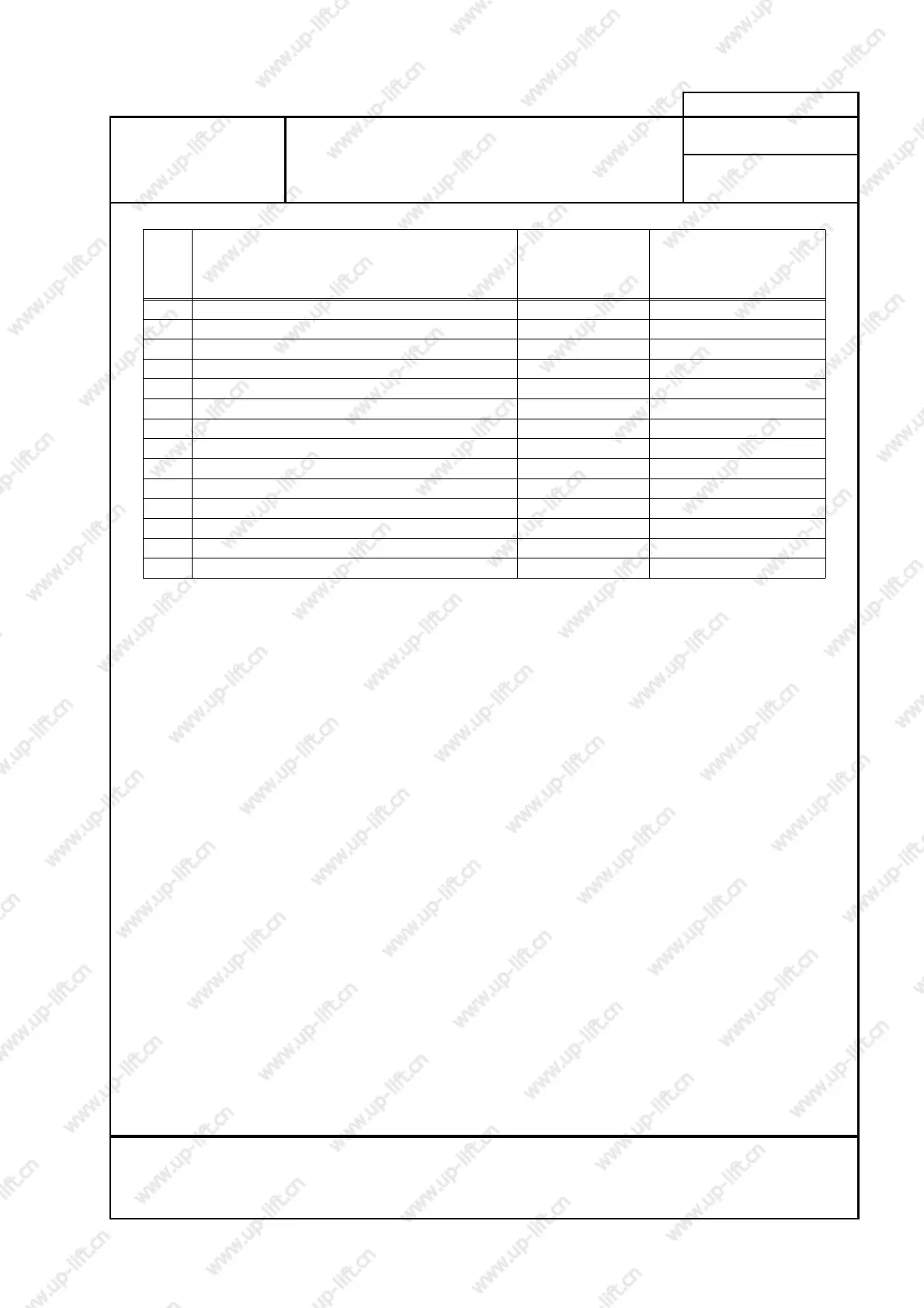

No

Check Point

(3.SETUP>> 3.1 Basic

>> 31a General >>A20 Load Sensor)

Data Remark

1 20a LS use Enable

2 Reset MCU board needless in "Enable"

3 Load 0% in the cage

4 20c Sensing Data >> LS data : A/D 9000~10000

5 20b Load Setting >> Load Set : 0% Settable

6 20b Load Setting >> Load Set : 0% YES → ENTER

7Buzzer once

8 Load 50% in the cage

9 20b Load Setting >> Load Set : 50% Settable

10 20b Load Setting >> Load Set : 50% YES → ENTER

11 Buzzer twice

12 20c Sensing Data >> LS data : % 50%

13 Load 0% in the cage

14 20c Sensing Data >> LS data : % 0%

[Table 10. LS Setup Procedure]

(4) Alignment

- As time goes on, check the "20c Sensing Data >> LS data : %".

- If the data is incorrect, do the alignment with HHT.

① Open the door completely in landing zone and make the inspection switch be on in the

machine room. (not in the car and not on the car)

② Load 0% in the cage

③ 20b Load Setting >> Load Align >> "settable"

④ push ENTER → select YES → push ENTER

⑤ After 2~3 seconds, check that the data "20c Sensing Data >> LS data : %" is 0%.

(5) Inverter setup(If necessary to adjust the inverter data)

- Finally, LS data is transferred to the inverter and inverter controls the start shock.

① "PROGRAM >> CONTROL >> 17.TQ_BIAS_SEC >> ANAL_TQ_BIAS "

② "PROGRAM >> CONTROL >> 23.TQ_BIAS_OFFSET >> 38.450 "

③ "PROGRAM >> CONTROL >> 35.DPRAM_TQ_USE >> 1 "

④ "PROGRAM >> CONTROL >> 22.TQ_BIAS_GAIN >> 1.000 "

⑤ Adjust the value "PROGRAM >> CONTROL >> 22.TQ_BIAS_GAIN " between ± 0.3~0.8

to decrease start shock.

Loading...

Loading...