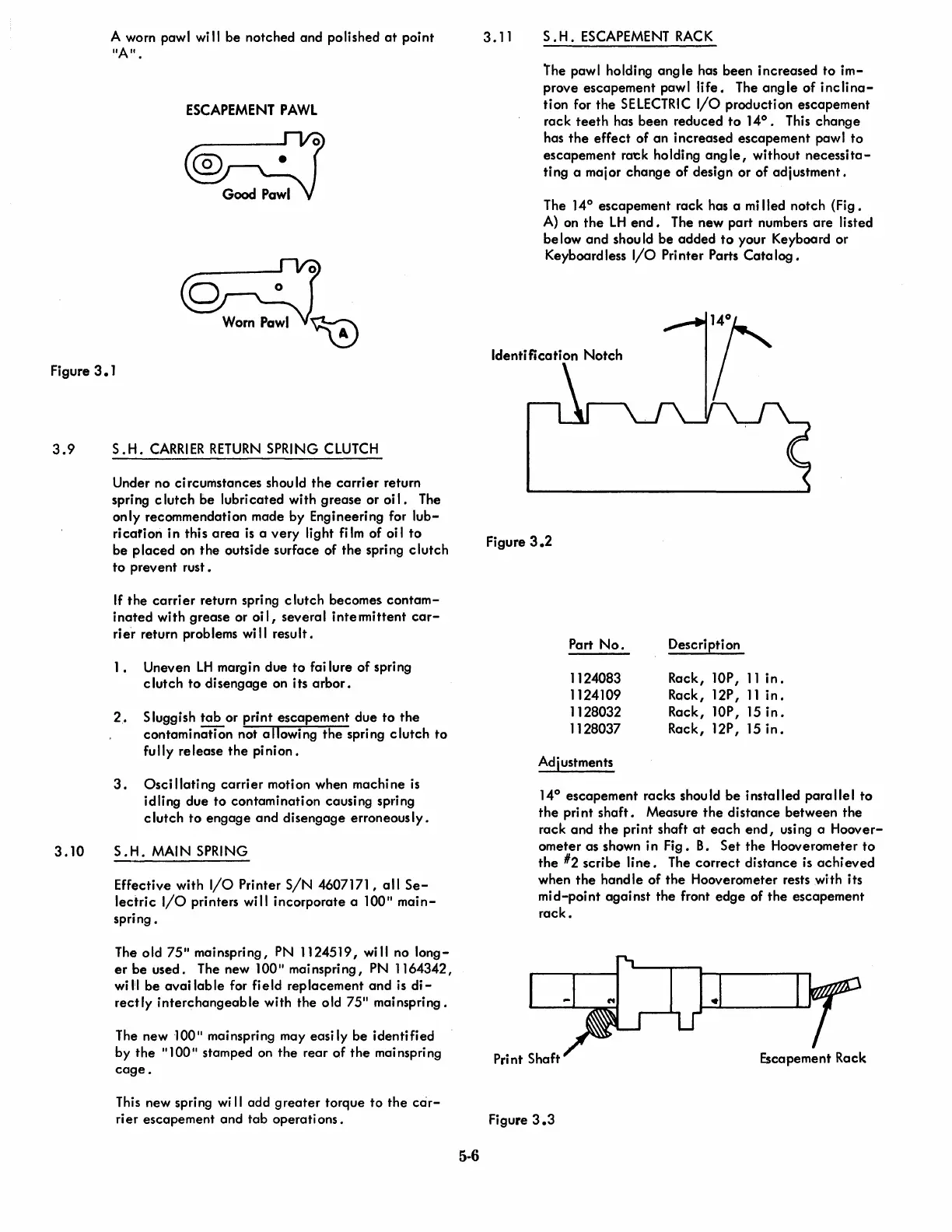

A worn pawl

wi

II

be

notched and polished

at

point

"A".

ESCAPEMENT

PAWL

Figure

3.1

3.9

S.H.

CARRIER

RETURN

SPRING

CLUTCH

3.10

Under no circumstances should

the

carrier

return

spring

clutch

be

lubricated with

grease

or

oil.

The

only

recommendation made by Engineering for

lub-

ricafion

in

this

area

is

a

very

light

fi

1m

of oi I

to

be

placed

on

the

outside surface of

the

spring

clutch

to

prevent rust.

If

the

carrier

return spring

clutch

becomes

contam-

inated

with

grease

or

oil,

several

intennittent

car-

rier

return problems

wi

II

result.

1.

Uneven

LH

margin due

to

fai lure

of

spring

clutch

to

disengage on its

arbor.

2.

Sluggish

tab

or print escapement due

to

the

contamination not allowing

the

spring

clutch

to

fully

release

the

pinion.

3.

asci

lIating

carrier

motion when machine

is

idling due

to

contamination causing spring

clutch

to

engage

and

disengage erroneous Iy.

S.H.

MAIN SPRING

Effective with

I/O

Printer

SIN

4607171,

all

Se-

lectric

I/O

printers will incorporate a 100"

main-

spring.

The old

75"

mainspring, PN 1124519,

wi

II

no

long-

er

be

used. The new 100" mai nspri

ng,

PN

1164342,

wHI

be

avai lable for field replacement

and

is

di-

recty

interchangeable

with the old 75" mainspring.

The new

100" mainspring may easi

Iy

be

identified

by

the

"100" stamped on the rear

of

the

mai nspri

ng

cage.

This new spring

wi

II

add

greater

torque

to

the

car-

ri

er

escapement

and

tab

operati ons .

5-6

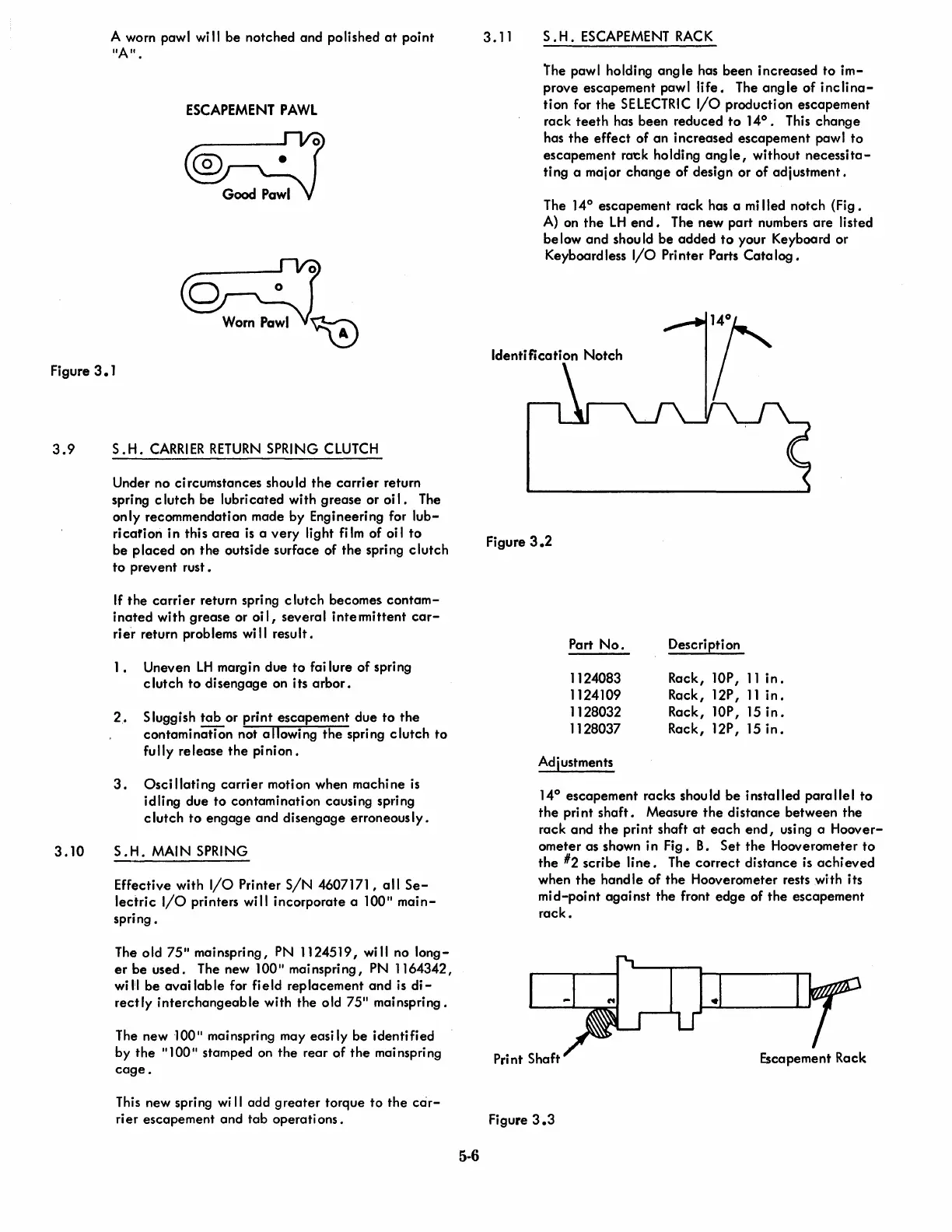

3.11

S.

H.

ESCAPEMENT

RACK

lhe

pawl holding

angle

has been increased

to

im-

prove escapement paw I Ii

fe.

The ang

Ie

of

inc

Ii

na-

tion for the

SELECTRIC

I/O

production escapement

rack

teeth

has been reduced

to

14°.

This

change

has

the

effect

of

an

increased escapement pawl

to

escapement rat:k holding

angle,

without

necessita-

ting a major

change

of design or

of

adjustment.

The 14° escapement rack has a

mi

lied notch (Fig.

A)

on

the

LH

end.

The new part numbers

are

listed

be

low

and

shou

Id

be

added

to

your Keyboard or

Keyboard less

I/O

Pri

nter

Parts

Cata

log •

Figure

3.2

Part

No.

Description

1124083

Rack,

lOP,

11

in.

1124109

Rack, 12P,

11

in.

1128032

Rack, lOP,

15

in.

1128037 Rack, 12P,

15

in.

Adjustments

14°

escapement racks should

be

installed

parallel

to

the

print

shaft.

Measure

the

distance

between

the

rack and

the

print shaft

at

each

end,

using a Hoover-

ometer as shown in

Fig.

B.

Set

the

Hooverometer

to

the

#2

scribe

line.

The

correct

distance

is

achieved

when

the

handle

of

the

Hooverometer rests with its

mid-point

against

the

front

edge

of

the

escapement

rack.

Escapement Rack

Figure

3.3

Loading...

Loading...