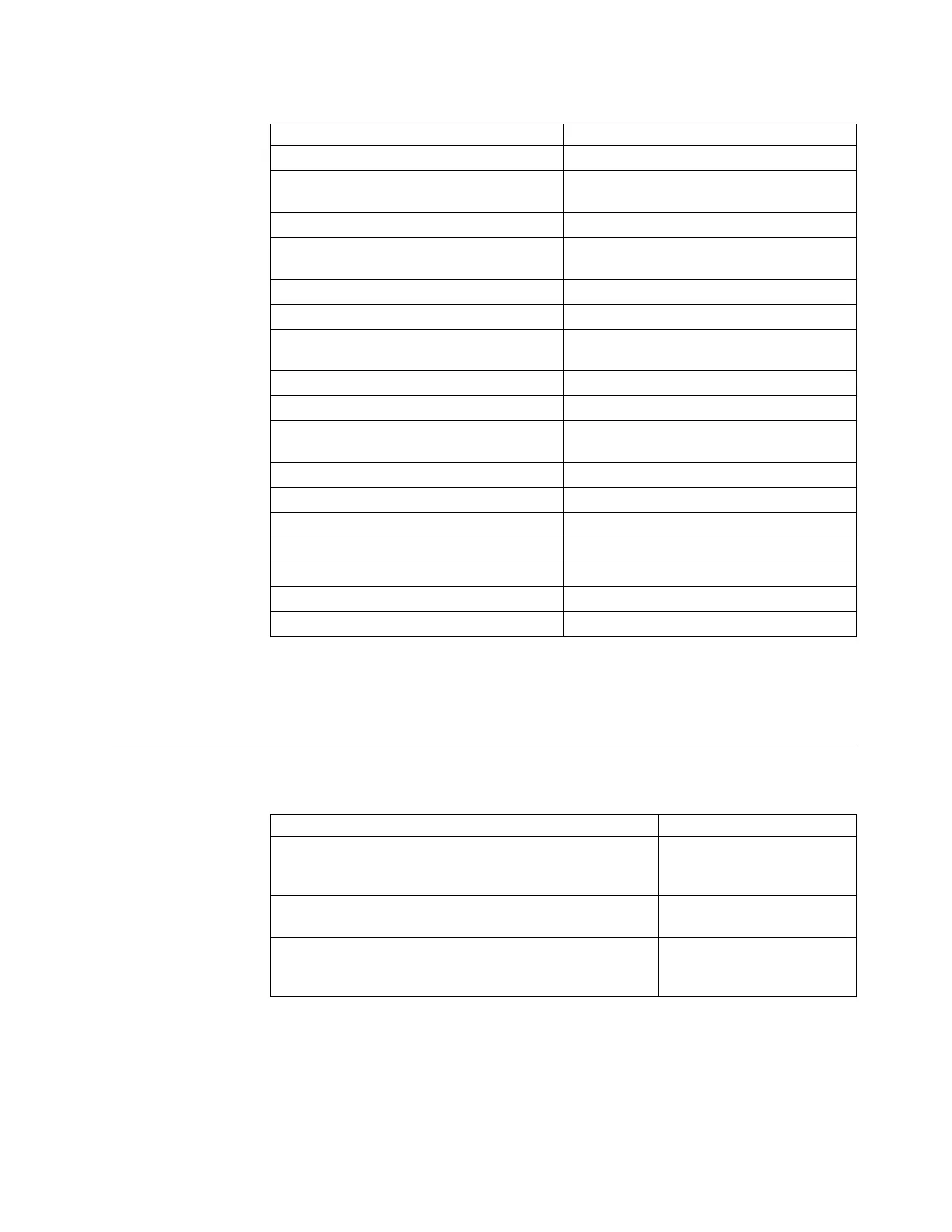

Table 42. Eaton-Williams cooling distribution unit specifications (continued)

Performance Properties

Pump capacity (design flow) 240 L/min (63.4 GPM)

Maximum pump head pressure 355 kPa (51.5 psi) at design duty, excluding

cabinet losses

Coolant (liquid) type Chilled water (with up to 30% glycol)

Primary liquid connections 1 1/2 in. flex tail for sweat connection, top

or bottom

Secondary liquid connections 3/4 in. quick connects, hydraulic ISO-B

Unit internal primary circuit liquid capacity Approximately 10.0 liters (2.6 gallons)

Unit internal secondary circuit liquid

capacity

Approximately. 32.0 liters (8.5 gallons)

Noise < 55 dBA at 3 meters

Electrical

Power supply 200 - 230 V, 3Ø, 50/60 Hz or 400 - 480 V, 3Ø,

50/60 Hz

Maximum power consumption 5.6 kVA at 480 V, 4.9 kVA at 208 V

Physical

Height 1825 mm (72 in.)

Width 800 mm (31.5 in.)

Depth 1085 mm (43 in.)

Weight (empty) 396 kg (870 lb)

Weight (filled) 438 kg (965 lb)

Note: Other industrial cooling distribution units can be used in a secondary

cooling loop with the rear-door heat exchanger, if they meet the specifications and

requirements that are described or referred to in this document.

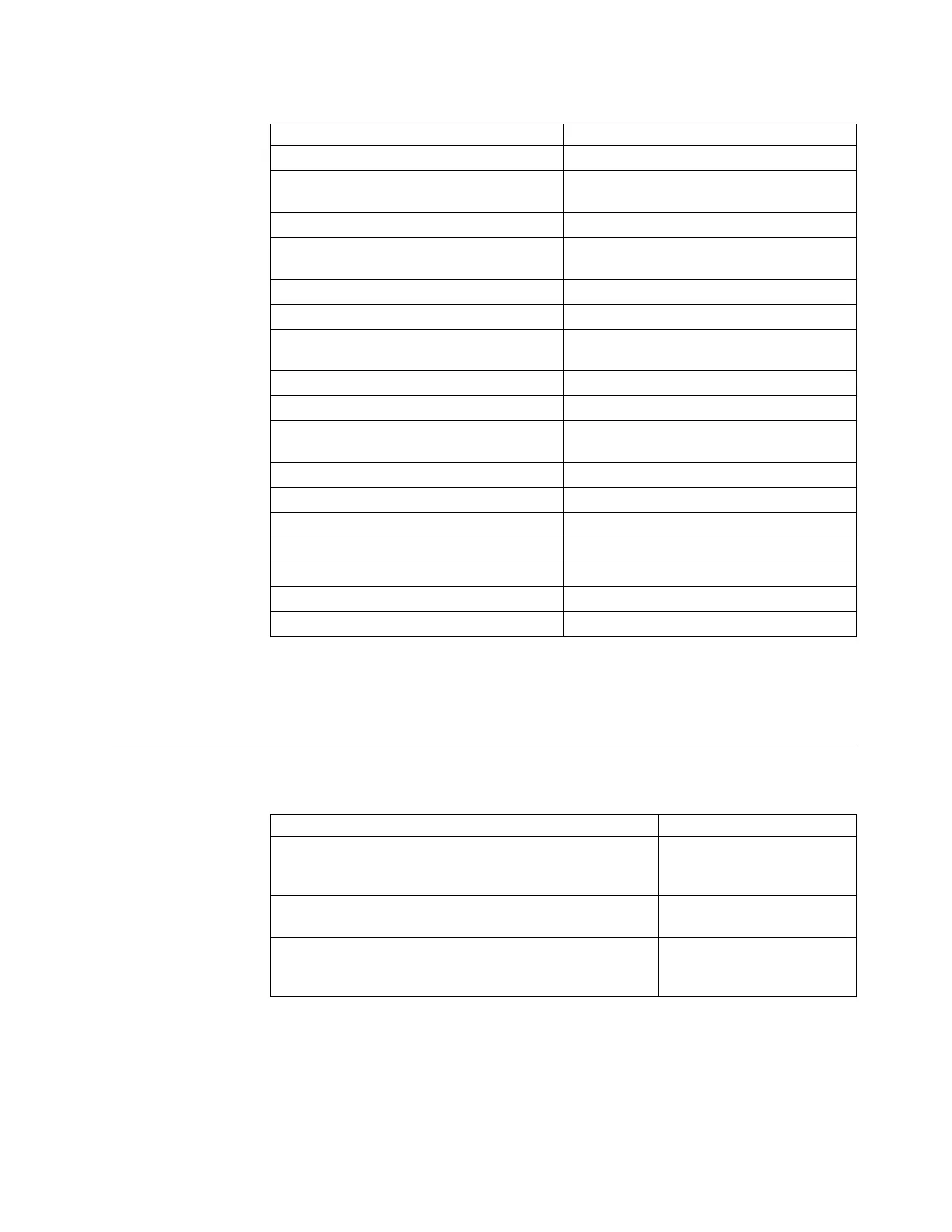

Maintenance schedule

Maintenance tasks are required at certain time intervals.

Task Schedule

Check the manifolds for temperature (make sure that the

top of the manifolds is cool) and sounds of air in the

system to ensure that the exchanger is correctly filled.

One month after installation

and again annually

Inspect the heat-exchanger fins for air blockage at the fins

(such as dust, dirt, and debris)

Annually

Inspect the entire length of the supply hose and return hose

for damage, age cracks, and kinks. Be sure to inspect at the

door and outside of the rack.

Annually

Chapter 10. Planning for the rear-door heat exchanger 91

Loading...

Loading...