CONTINUOUSFANOPERATION

Continuousfanspeedoperatesatthe lowstagecooling

speedforallmodels.

COOLING

1.TurnelectricpowerOFF

2.SetthermostatHeat-Coolselectto COOL.

3.Adjustthermostatsettingto belowroomtemperature.

4.TurnpowerON,for approximatelyoneminute,then

OFF.Duringpowerapplicationcheckthefollowing:

a.Contactor- ContactsClosing

b.Compressor- ON

c.Condenserfanmotor- ON

d.CirculatingAirBlower- ON0 seconddelay

5.TurnpowerOFEcheckthefollowing:

a. Contactorcontactsopening.

b. Compressor- OFF

c. Condenserfanmotor- OFF

d. Circulatingblower- OFFafter90seconddelayon

allmodels.

9. START-UP PROCEDURES

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Do NOT attempt to light the burner with a match or

flame of any kind.

CHECK BEFORE STARTING

1. Check that the blower motor speed terminal block is

running the correct heating and cooling speeds.

2. Check to see that clean, properly sized air filters are

installed.

3. Replace all service access panels.

FIRE OR EXPLOSION HAZARD.

Failure to follow this warning could result in

personal injury and/or death.

Turn OFF gas at shut off before connecting U-tube

manometer.

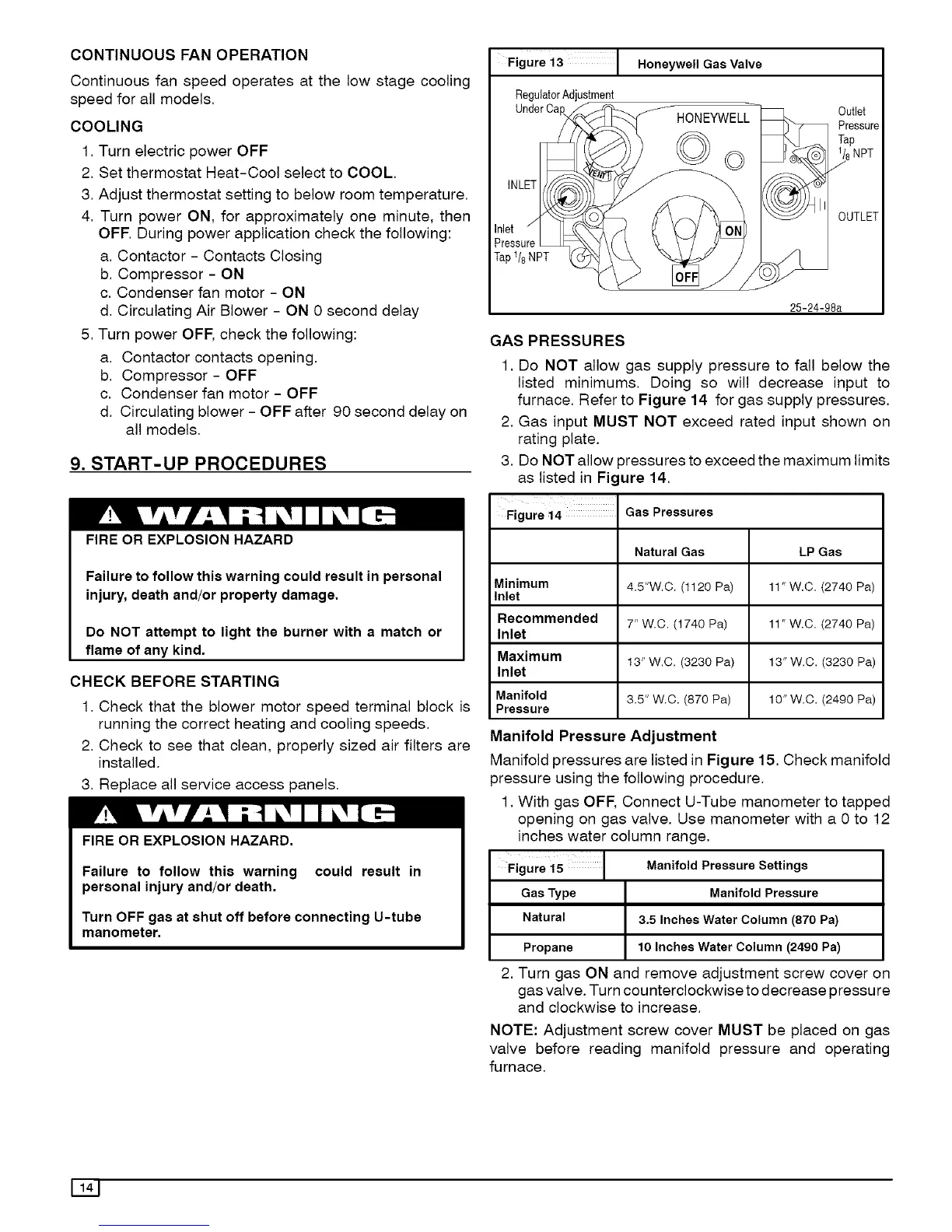

Figure i3 I Honeywell Gas Valve

RegulatorAdjustment

UnderCa

Inlet

Pressure

Tap1/8NPT

HONEYWELL

©

Outlet

Pressure

Tap

1/8NPT

/

OUTLET

25-24-98a

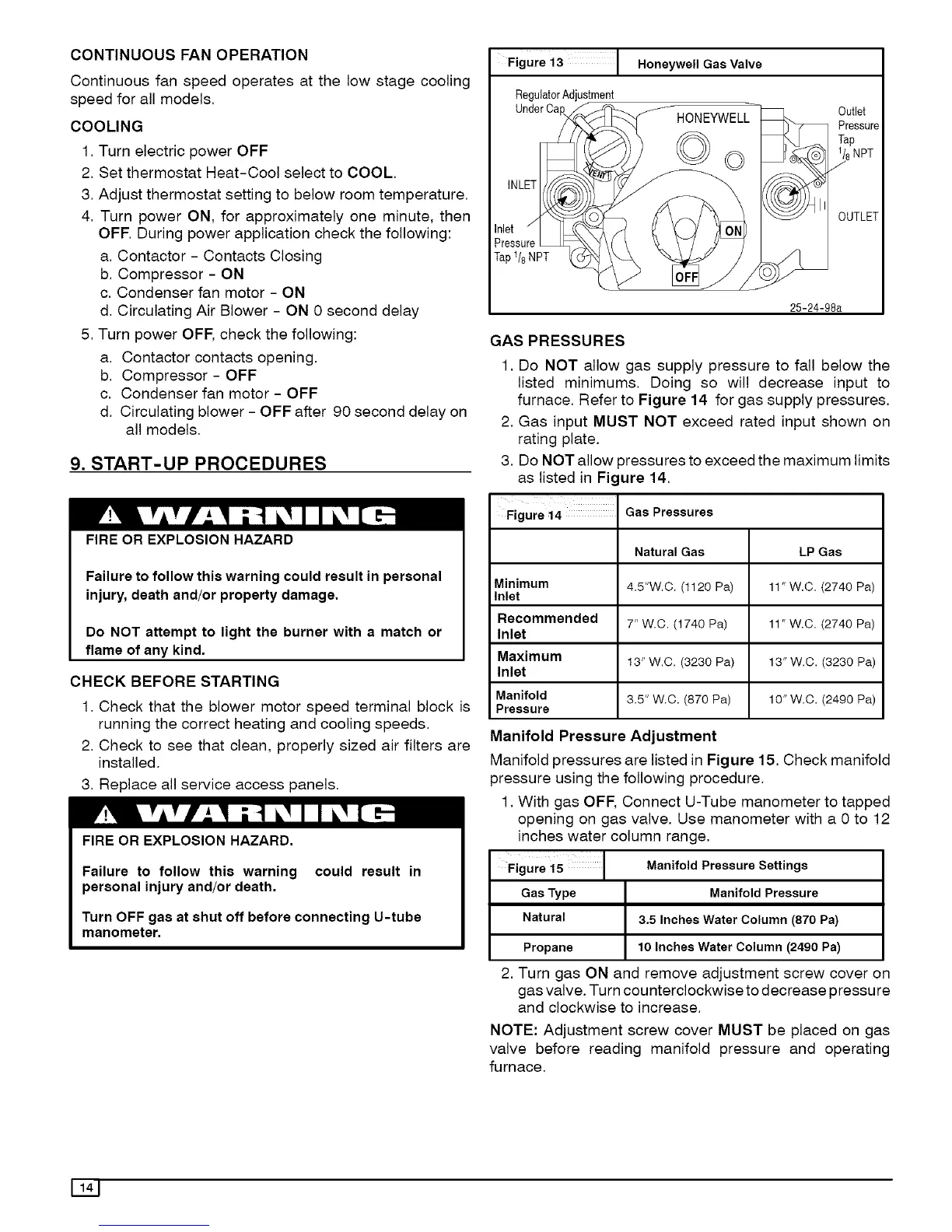

GAS PRESSURES

1. Do NOT allow gas supply pressure to fall below the

listed minimums. Doing so will decrease input to

furnace. Refer to Figure 14 for gas supply pressures.

2. Gas input MUST NOT exceed rated input shown on

rating plate.

3. Do NOT allow pressures to exceed the maximum limits

as listed in Figure 14.

Figure 14

Gas Pressures

Natural Gas LP Gas

Minimum 4.5"W.C. (1120 Pa) 11" W.C. (2740 Pa)

Inlet

Recommended 7" W.C. (1740 Pa) 11" W.C. (2740 Pa)

Inlet

Maximum 13" W.C. (3230 Pa) 13" W.C. (3230 Pa)

Inlet

Manifold 3.5" W.C. (870 Pa) 10" W.C. (2490 Pa)

Pressure

Manifold Pressure Adjustment

Manifold pressures are listed in Figure 15. Check manifold

pressure using the following procedure.

1. With gas OFE Connect U-Tube manometer to tapped

opening on gas valve. Use manometer with a 0 to 12

inches water column range.

Figure 15 Manifold Pressure Settings

Gas Type Manifold Pressure

Natural 3.5 Inches Water Column (870 Pa)

Propane 10 Inches Water Column (2490 Pa)

2. Turn gas ON and remove adjustment screw cover on

gas valve. Turn counterclockwise to decrease pressure

and clockwise to increase.

NOTE: Adjustment screw cover MUST be placed on gas

valve before reading manifold pressure and operating

furnace.

1141

Loading...

Loading...