NOTE: The orifice sizes in the chart above derate the input rate at 4% per 1000 feet above sea level for altitudes exceeding 2000 feet

above sea level. If converting from LP gas to Natural Gas at altitudes exceeding 2000 feet above sea level, use part number

330732-401, plus the required orifice size # shown in Table 1. Natural Gas data is based on 0.60 specific gravity, a heating value of 1030

Btu/ft3., and 3.5" W.C. manifold pressure. For fuels with different specific gravity, consult the National Fuel Gas Code NFPA

54-2005/ANSI Z223.1-2005 or National Standard of Canada, Natural Gas and Propane Installation Code CSA B149.1-05.

Table 2 LP GAS ORIFICE SIZING

MEAN ELEVATION FEET ABOVE SEA LEVEL

0 to 2000 2001 to 4000 4001 to 7000 7001 to 9000 9001 to 10,000

Nominal Heating Orifice Kit Orifice Kit Orifice Kit Orifice Kit Orifice Kit

Size Drill # Number Drill # Number Drill # Number Drill # Number Drill # Number

All Sizes 55 1173857 55 1173857 56 1173859 56 1173859 57 1173861

NOTE: The orifice sizes in the chart above derate the input rate at 4% per 1000 feet above sea level for altitudes exceeding 2000 feet

above sea level. LP Gas data is based on 1.52 specific gravity, a heating value of 2500 Btu/ft3., and 10.0" W.C. manifold pressure. For

fuels with different specific gravity, consult the National Fuel Gas Code NFPA 54-2005/ANSI Z223.1-2005 or National Standard of

Canada, Natural Gas and Propane Installation Code CSA B149.1-05.

Changing Orifices

ELECTRICAL SHOCK, FIRE AND/OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Shut off electric power at unit disconnect or service

panel and shut off gas at manual shut off valve before

beginning the following procedure.

Changing orifices requires a qualified service

technician.

1. Shut OFF gas at manual shut off valve.

2. Shut OFF electric power at unit disconnect or service

panel. If unit is still running, allow 3 minutes after gas

shut off before turning off power.

3. Disconnect the wires from the gas valve, sparker, and

flame sensor.

4. Remove the four screws holding the manifold to the

manifold brackets.

5. Carefully remove the manifold with the gas valve

attached.

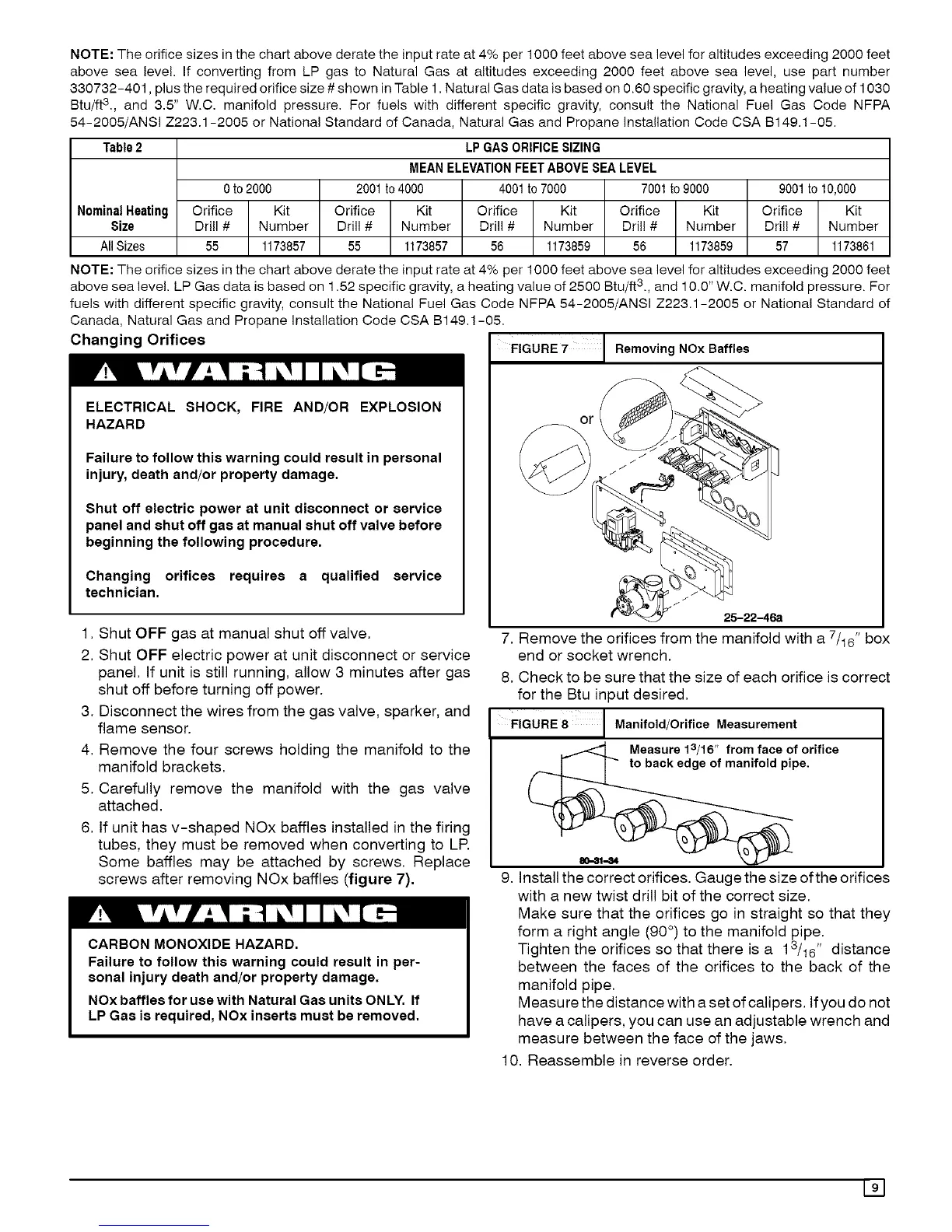

6. If unit has v-shaped NOx baffles installed in the firing

tubes, they must be removed when converting to LR

Some baffles may be attached by screws. Replace

screws after removing NOx baffles (figure 7).

CARBON MONOXIDE HAZARD.

Failure to follow this warning could result in per-

sonal injury death and/or property damage.

NOx baffles for use with Natural Gas units ONLY. If

LP Gas is required, NOx inserts must be removed.

FIGURE 7 Removing NOx Baffles

25-22-46a

7. Remove the orifices from the manifold with a 7/t6" box

end or socket wrench.

8. Check to be sure that the size of each orifice is correct

for the Btu input desired.

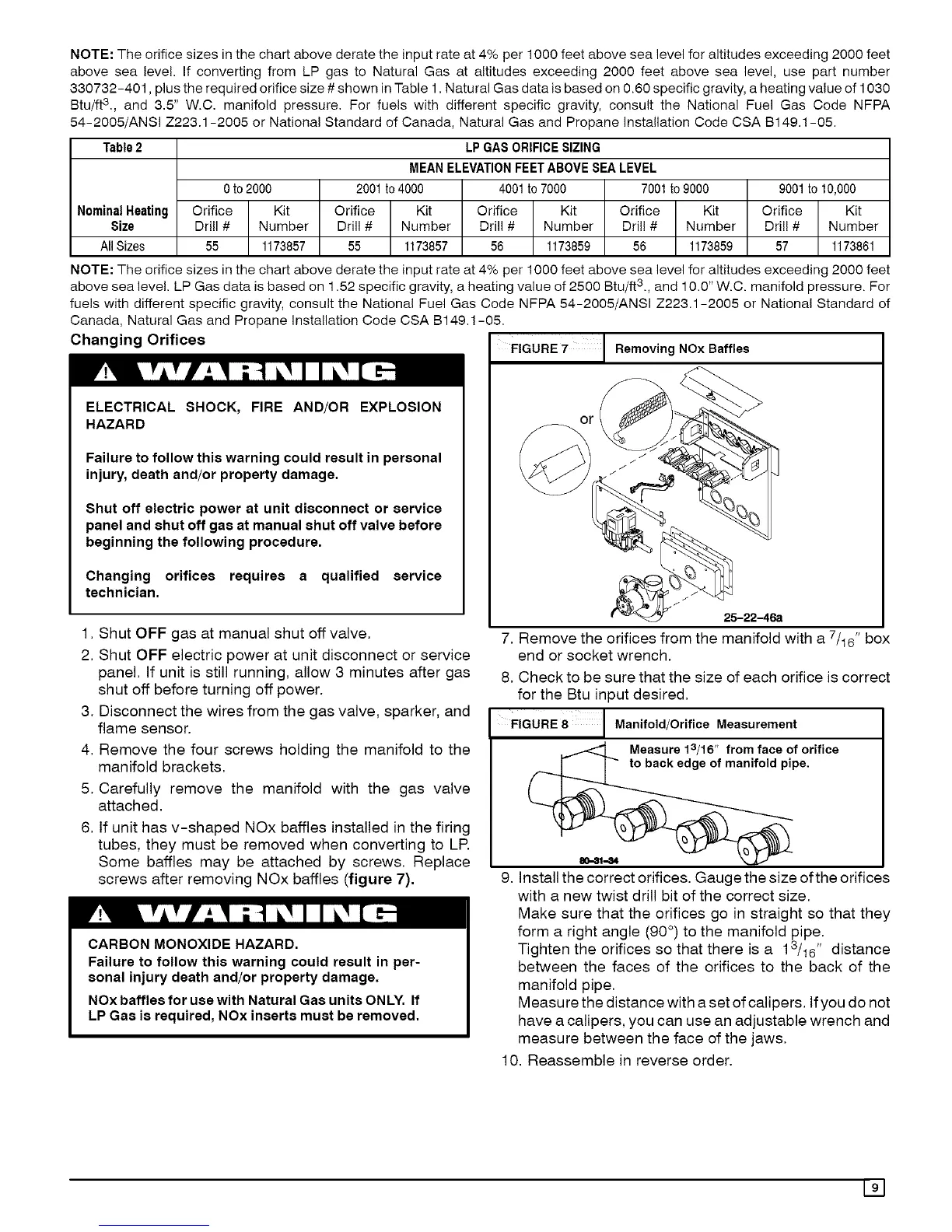

FIGURE 8 Manifold/Orifice Measurement

Measure 13/16 " from face of orifice

_ _ifold pipe.

9. Install the correct orifices. Gauge the size ofthe orifices

with a new twist drill bit of the correct size.

Make sure that the orifices go in straight so that they

form a right angle (90 °) to the manifold pipe.

Tighten the orifices so that there is a ] 3/t6" distance

between the faces of the orifices to the back of the

manifold pipe.

Measure the distance with a set of calipers. Ifyou do not

have a calipers, you can use an adjustable wrench and

measure between the face of the jaws.

10. Reassemble in reverse order.

191

Loading...

Loading...