I Combination Units Installation Instructions

soot and severe rust or corrosion and any obstructions due to

leaves, spider webs, etc. Clean as required.

Cooling Season Checks (Monthly)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of leaves,

grass clippings or other debris. Grass should be kept short in front

of the condenser inlet. Shrubbery MUST be trimmed back so it is

no closer than 30 inches to unit.

Condensate Drain

Check for condensate drainage. Clean as required.

NOTE: When unit isoperating in cooling mode under high humid-

ity ambient conditions, condensate can form in the burner

compartment and may drip from front of the compartment. This

condition is NOT harmful to unit.

Annual Maintenance and Inspection

2. Remove the four screws securing the blower motor hous-

ing. If unit has a support bracket, remove the two screws

securing the bracket.

3. Remove the two red wires attached to the limit switch.

4. Slide entire housing toward you. This will allow easier ac-

cess to the speed tap block, motor, and wires.

5. After access, replace all wires, screws, and connections.

Motor removal and replacement

The blower motor may be replaced while accessing it using meth-

od 1. To replace motor, reach behind blower housing and locate

blower wheel set nut. Loosen set nut, all wires from motor, and

four pins on mounting cradle. Pull motor towards you. To replace

motor, reverse this procedure.

Method 2

This method is required to replace or repair blower wheel, blower

housing, or any unreachable components behind blower assem-

bly.

1. Repeat steps 1 through 4 in method 1.

Electrical shock hazard.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

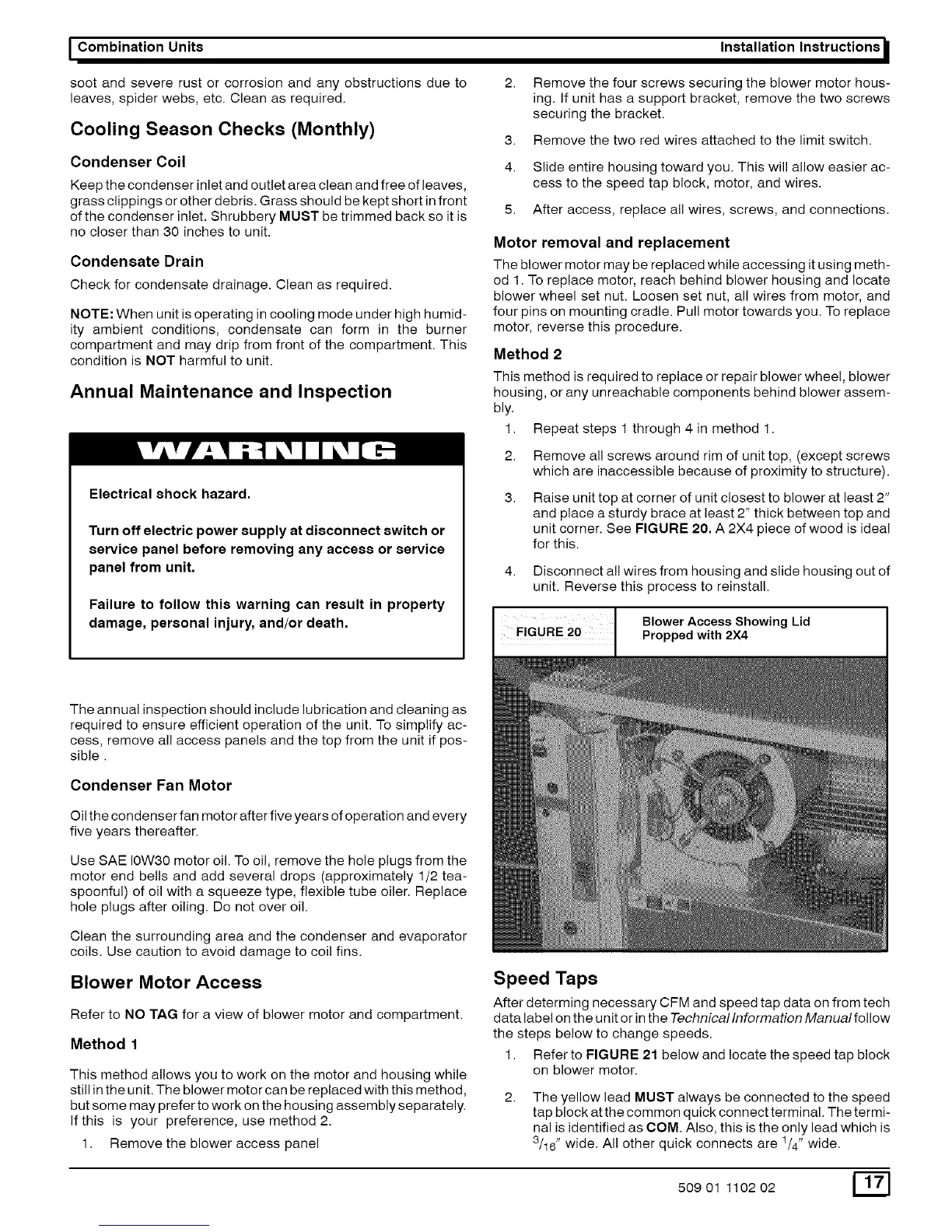

2.

3.

Remove all screws around rim of unit top, (except screws

which are inaccessible because of proximity to structure).

Raise unit top at corner of unit closest to blower at least 2"

and place a sturdy brace at least 2" thick between top and

unit corner. See FIGURE 20. A 2X4 piece of wood is ideal

for this.

4. Disconnect al! wires from housing and slide housing out of

unit. Reverse this process to reinstall.

FIG uRE 20 ProppedBI°werAcceSSwith2x4Sh°wing Lid

The annual inspection should include lubrication and cleaning as

required to ensure efficient operation of the unit. To simplify ac-

cess, remove all access panels and the top from the unit if pos-

sible.

Condenser Fan Motor

Oil the condenser fan motor after five years of operation and every

five years thereafter.

Use SAE 10W30 motor oil. To oil, remove the hole plugs from the

motor end bells and add several drops (approximately 1/2 tea-

spoonful) of oil with a squeeze type, flexible tube oiler. Replace

hole plugs after oiling. Do not over oil.

Clean the surrounding area and the condenser and evaporator

coils. Use caution to avoid damage to coi! fins.

Blower Motor Access

Refer to NO TAG for a view of blower motor and compartment.

Method 1

This method allows you to work on the motor and housing while

still in the unit. The blower motor can be replaced with this method,

but some may prefer to work on the housing assembly separately.

If this is your preference, use method 2.

1. Remove the blower access panel

Speed Taps

After determing necessary CFM and speed tap data on from tech

data label on the unit or in the Technicallnformation Manualfollow

the steps below to change speeds.

1. Refer to FIGURE 21 below and locate the speed tap block

on blower motor.

The yellow lead MUST always be connected to the speed

tap block atthe common quick connect terminal. The termi-

nal is identified as COM. Also, this is the only lead which is

1 ,

3/16" wide. All other quick connects are /4' wide.

50901 110202 [_[]

Loading...

Loading...