85

TILT-A-WAY HYDRAULIC VERTICAL PIVOT GATE

GENERAL ARRANGEMENT AND MAINTENANCE

MAINTENANCE MUST BE DONE EVERY 5000 OPERATIONS OR YEARLY

HYJG 1

DWG # HYJG-244

TILT-A-WAY

GENERAL MAINTENANCE

HYJg-244

Check all safety devices for proper function monthly.

Check interior of pedestal for any accumulation of trash caused by blowing wind and

remove. (Monthly).

The following maintenance steps should be preformed every 5000 operations or yearly.

1. Check hydraulic fluid level with site gauge on oil reservoir. Level to be

approximately 2 ½” below the top of reservoir. If oil is required, add Citgo-CP

hydraulic fluid (this hydraulic fluid is blue in color). Check oil level with cylinder

retracted.

2. Clean and lubricate spring tension screws with “general purpose grease” to

prevent rusting.

3. Lubricate with “general purpose grease such as a bearing grease” all points

equipped with zerk fitting.

A. Barrier carriage pivot bearing. Two bearings one each side.

B. Cylinder anchor pivot.

C. Cylinder rod end pivot bearing.

4. Check gate balance. Open gate to mid travel, and stop. Turn power off, and open

manual valves on front of hydraulic pump unit. Gate should remain at mid travel

position. If gate moves see page 68 for balance adjustment. Close manual valves,

and turn power on. Return gate to closed position.

5. Inspect balance cables for broken strands. Replace cable if there are five broken

strands per lay or ten broken strands over all. See page 71 for cable replacement

instructions.

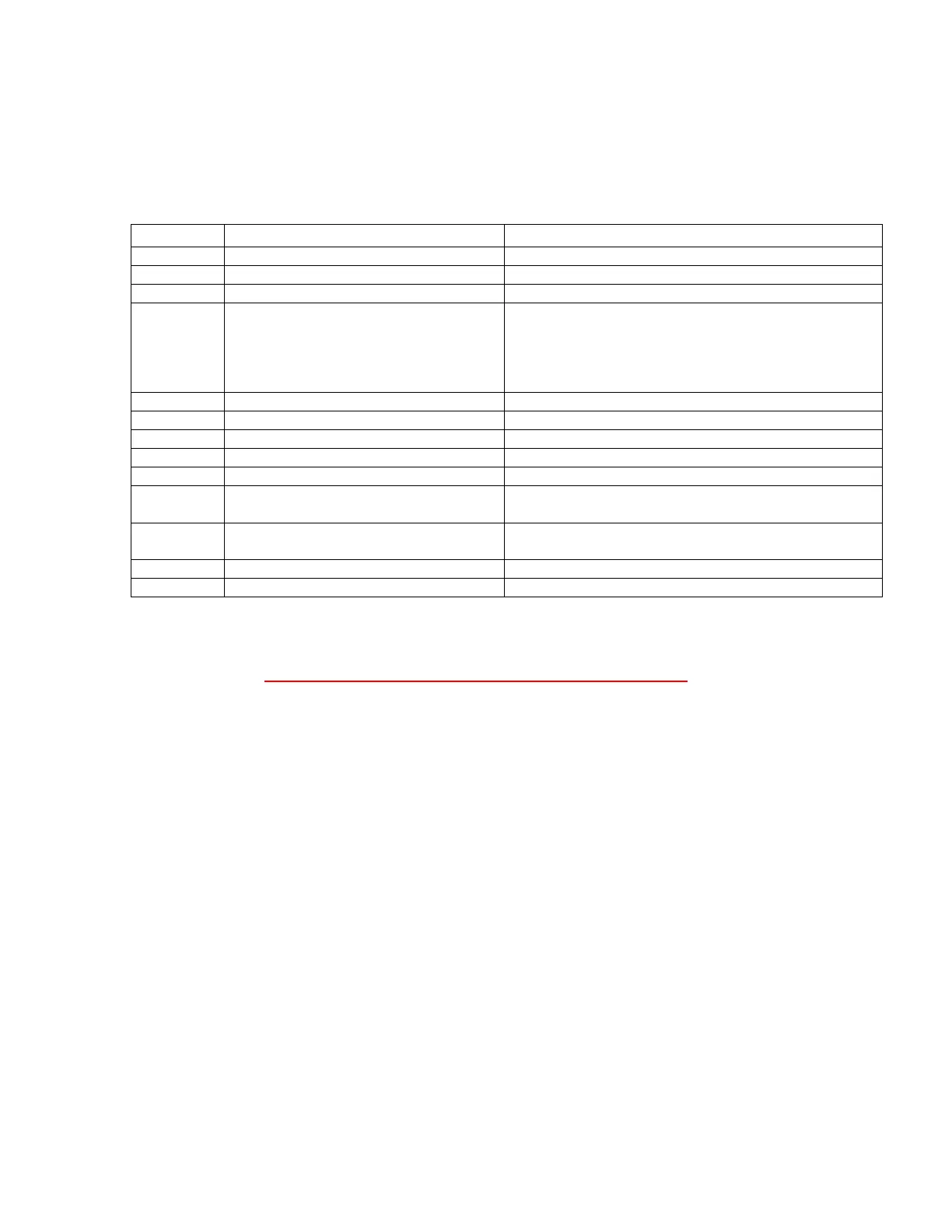

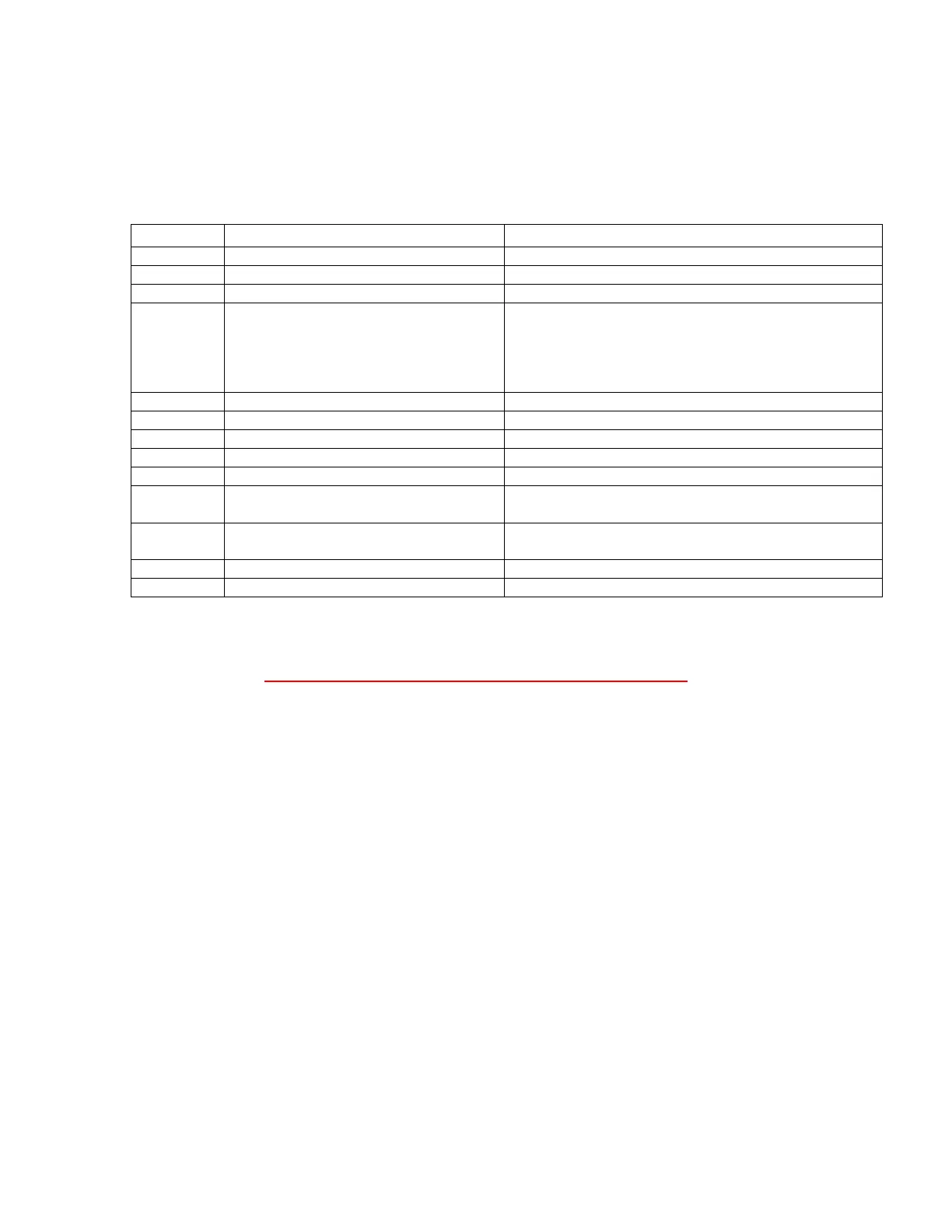

REF NO.

DESCRIPTION

For covering. See Drawing

Hydraulic Pump & Reservoir

Electrical Control Enclosure

24 VDC 120 VAC

208 / 240 VAC Single Phase

208 /240 VAC Three Phase

480 VAC Three Phase

See Drawing HYJG-204 Page 9

See Drawing HYJG-207 Page 13

See Drawing HYJG-210 Page 17

See Drawing HYJG-213 Page 21

Balance System Cable Guide Assembly.

Balance System Tension Cable

Balance system Tension Spring

Balance System Spring Tension

Adjusting Limit

ety Switch”. See Drawing HYJG

Page 87

Hydraulic Actuating Cylinder

Cylinder Control Actuating System

Loading...

Loading...