G FOREWORD

The aim of this section is the description of operations needed to operate the OCEAN SEVEN 310 probes

equipped with the IDRONAUT innovative not harmful antifouling device (patent pending).

The antifouling is available only if the OS310

probe has the 100 mm POM housing.

G.1 THE ANTIFOULING DEVICE

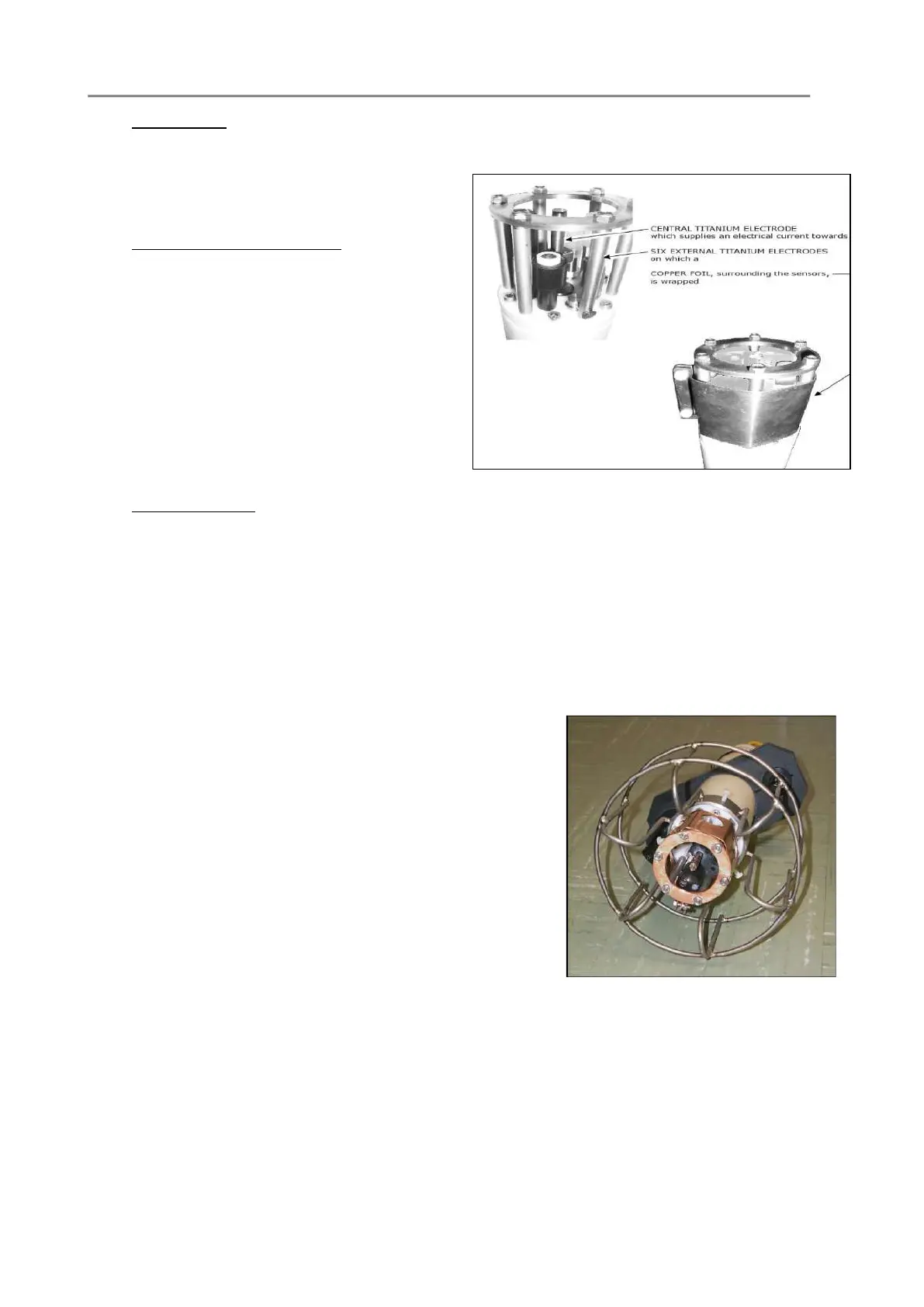

The antifouling kit, installed by the measuring

sensors of the Ocean Seven 3xx probes, is

composed of a central titanium electrode which

supplies an electrical current towards six

external titanium electrodes on which a copper

foil (replaceable) surrounding the sensors, can

be wrapped. In addition to chloride formation,

there is copper dissolution in an ionic form by

the sensors. The copper foil has a typical

endurance of more than one year. The sensors

are washed when the probe starts profiling.

G.2 HOW IT WORKS

The fouling probably represents the major difficulty during continuous monitoring of waters and,

although many efforts in research at worldwide level have been dedicated to this problem during the

past decades, a definitive solution is not yet available. Therefore, a compromise must be found each

time according to the specific difficulty met with.

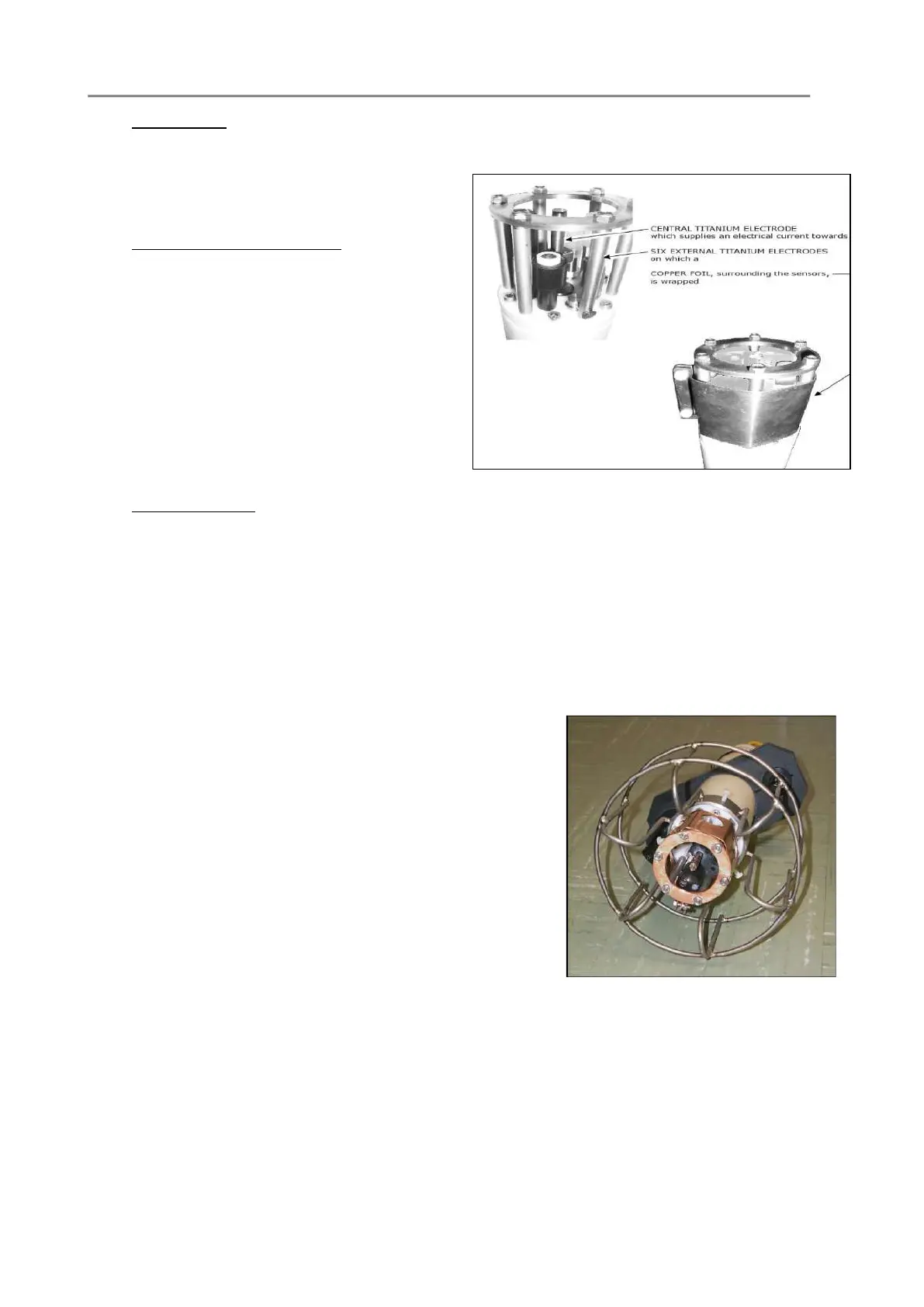

Since our monitoring equipment (Buoy Profiler, OCEAN SEVEN 310) operates to study the

environmental conditions where fishes grow, we have not taken into consideration the antifouling

system based on the slow release of Tributyltin (TBT) oxide or other heavily poisoning chemical

substances. We have then decided to simply use metallic copper to act as an antifouling protection by

the measuring sensors. The picture shows an OCEAN SEVEN 310 probe during the antifouling device

development test with the antifouling device not active after a monitoring of two months.

A foil of copper (1 mm thickness) has been placed around the

sensor cage in such a way that it can be easily replaced with a

new one without damaging the measuring sensors and to also

avoid reducing the flow of water to be measured. The

presence of this simple device has, on average, increased the

time between each cleaning from 1 to 2 weeks only.

This is because the metallic surface of the copper easily

becomes oxidised in a few days and, after that, it loses most

of its activity. In fact, copper is not able any more to dissolve

in an ionic form in the water surrounding the sensors and the

inside of the copper protection.

Therefore, to avoid the copper passivation, we have installed

in the centre of the probe, where the measuring sensors are

placed, a titanium electrode, which “impresses” an electrical current versus the copper foil. In this way

the copper foil, which acts as a flow-measuring chamber, is always clean and so this allows the copper

dissolution in an ionic form. This effect has drastically decreased the formation of fouling by the

measuring sensors.

The current between the titanium and the copper electrodes is applied when the probe is not carrying

out measurements. Vice versa, when the probe starts descending, the current is not applied any more

and the water to be measured flows between the sensors and washes them of the ionic copper previously

dissolved. This improvement considerably increases the “time between cleanings” up to three/four

weeks, depending on the water quality.

To the best of our knowledge, this kind of antifouling system does not appear in the scientific literature and

Loading...

Loading...