C32

1-241-23

C32

C12

1-20

C12

1-21

1

3

2

5

6

4

1

2

3

4

6

5

7

8

10 - IE

INSTALLATORUSERTECHNICIAN

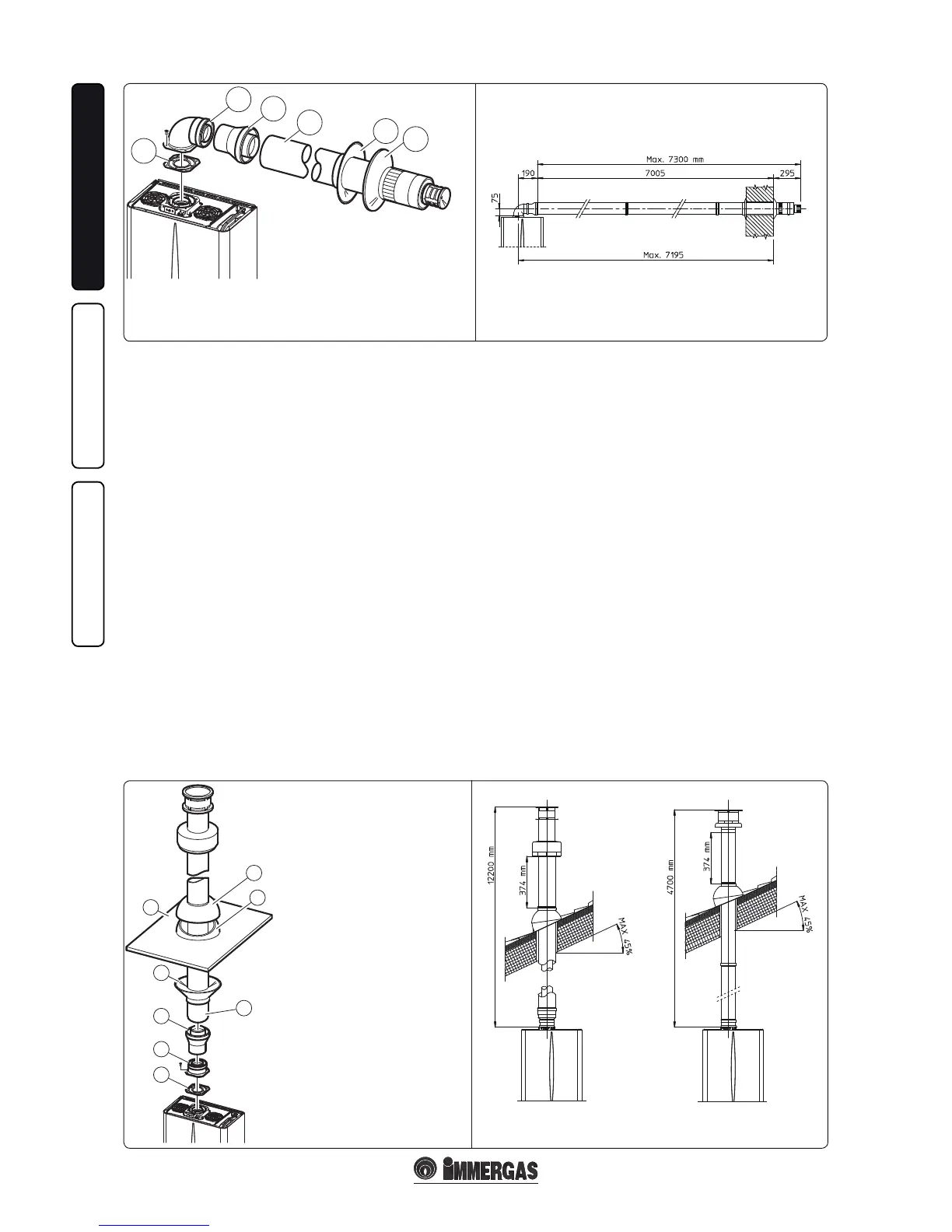

Vertical kit with aluminium tile Ø 80/125. Kit

assembly (Fig. 1-23): install the concentric ange

(2) on the central hole of the boiler inserting the

gasket (1) and tighten using the screws in the

kit. Fit the male end (smooth) of the adapter (3)

into the female end of the concentric ange (2).

Imitation aluminium tile installation. Replace the

tile with the aluminium sheet (5), shaping it to

ensure that rainwater runs o. Position the xed

half-shell (7) and insert the intake-exhaust pipe

(6). Fit the Ø 80/125 concentric terminal pipe

with the male end (6) (smooth) to the female end

of the adapter (3) (with lip gasket) up to the stop;

making sure that the wall sealing plate has been

tted, this will ensure sealing and joining of the

elements making up the kit.

• Coupling extension pipes and concentric el-

bows. To install snap-t extensions with other

elements of the fume extraction elements as-

sembly, proceed as follows: Install the concen-

tric pipe or elbow with the male side (smooth)

on the female section (with lip seal) to the end

stop on the previously installed element. is

will ensure sealing and joining of the elements

correctly.

Important: if the exhaust terminal and/or exten-

sion concentric pipe needs shortening, consider

that the internal pipe must always protrude by 5

mm with respect to the external pipe.

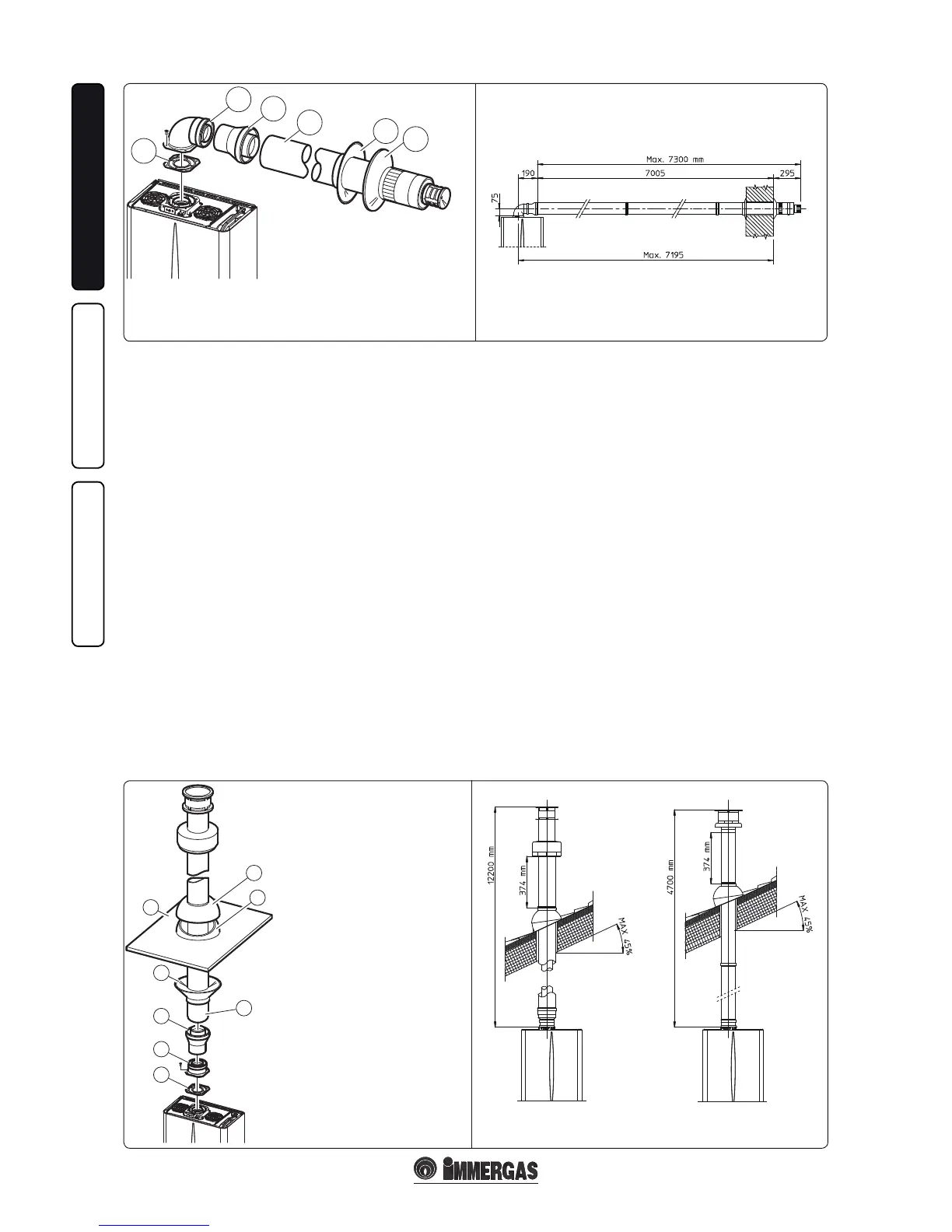

is specic terminal enables ue exhaust and

air intake, necessary for combustion, in a vertical

direction.

N.B.: e Ø 80/125 vertical kit with aluminium

tile enables installation on terraces and roofs with

a maximum slope of 45% (24°) and the height

between the terminal cap and half-shell (374

mm) must always be respected.

e vertical kit with this conguration can be

extended up to a maximum of 12200 mm vertical

rectilinear, with the terminal included (Fig. 1-24).

is conguration corresponds to a resistance

factor of 100. In this case the special extensions

must be requested.

The terminal Ø 60/100 can also be used for

vertical exhaust, in conjunction with concentric

flange code 3.011141 (sold separately). The

height between the terminal cap and half-shell

(374 mm) must always be respected (Fig. 1-24).

e vertical kit with this conguration can be

extended up to a maximum of 4700 mm vertical

rectilinear, with the terminal included (Fig. 1-24).

Separator kit Ø 80/80. e Ø 80/80 separator

kit, allows separation of the exhaust ues and

air intake pipes according to the diagram shown

in the gure. Combustion products are expelled

from pipe (S). Air is taken in through pipe (A)

for combustion. The intake pipe (A) can be

installed either on the right or le hand side of

the central exhaust pipe (S). Both ducts can be

routed in any direction.

• Kit assembly (Fig. 1-25): install ange (4) on

the central hole of the boiler, tting the gasket

(1), and tighten with the at-tipped hex screws

included in the kit. Remove the flat flange

present in the lateral hole with respect to the

central one (according to needs) and replace it

with the ange (3), positioning the gasket (2)

already present in the boiler and tighten using

the supplied self-threading screws. Fit the male

end (smooth) to the bends (5) in the female end

of the anges (3 and 4). Fit the intake terminal

(6) with the male section (smooth) in the

female section of the bend (5) to the end stop,

ensuring that the internal and external rings are

tted. Fit the exhaust pipe (9) with the male end

(smooth) to the female end of the bend (5) up

to the stop; making sure that the internal wall

sealing plate has been tted. is will ensure

sealing and joining of the elements making up

the kit.

e kit includes:

N°1 - Gasket (1)

N°1 - Concentric bend Ø 60/100 (2)

N°1 - Adapter Ø 60/100 for Ø 80/125 (3)

N°1 - Concentric intake-exhaust terminal

Ø 80/125 (4)

N°1 - Internal white wall sealing plate (5)

N°1 - External grey wall sealing plate (6)

e kit includes:

N°1 - Gasket (1)

N°1 - Female concentric ange (2)

N°1 - Adapter Ø 60/100 for Ø 80/125 (3)

N°1 - Wall sealing plate (4)

N°1 - Aluminium tile (5)

N°1 - Concentric intake-exhaust terminal

Ø 80/125 (6)

N°1 - Fixed half-shell

N°1 - Mobile half-shell

MAXIMUM LENGTH

MAXIMUM LENGTH

Loading...

Loading...