C82

1-25

C42

C52

1-26

1-28

C82

1-27

4

6

5

1

3

2

7

8

5

9

7

A

S

11 - IE

INSTALLATORUSERTECHNICIAN

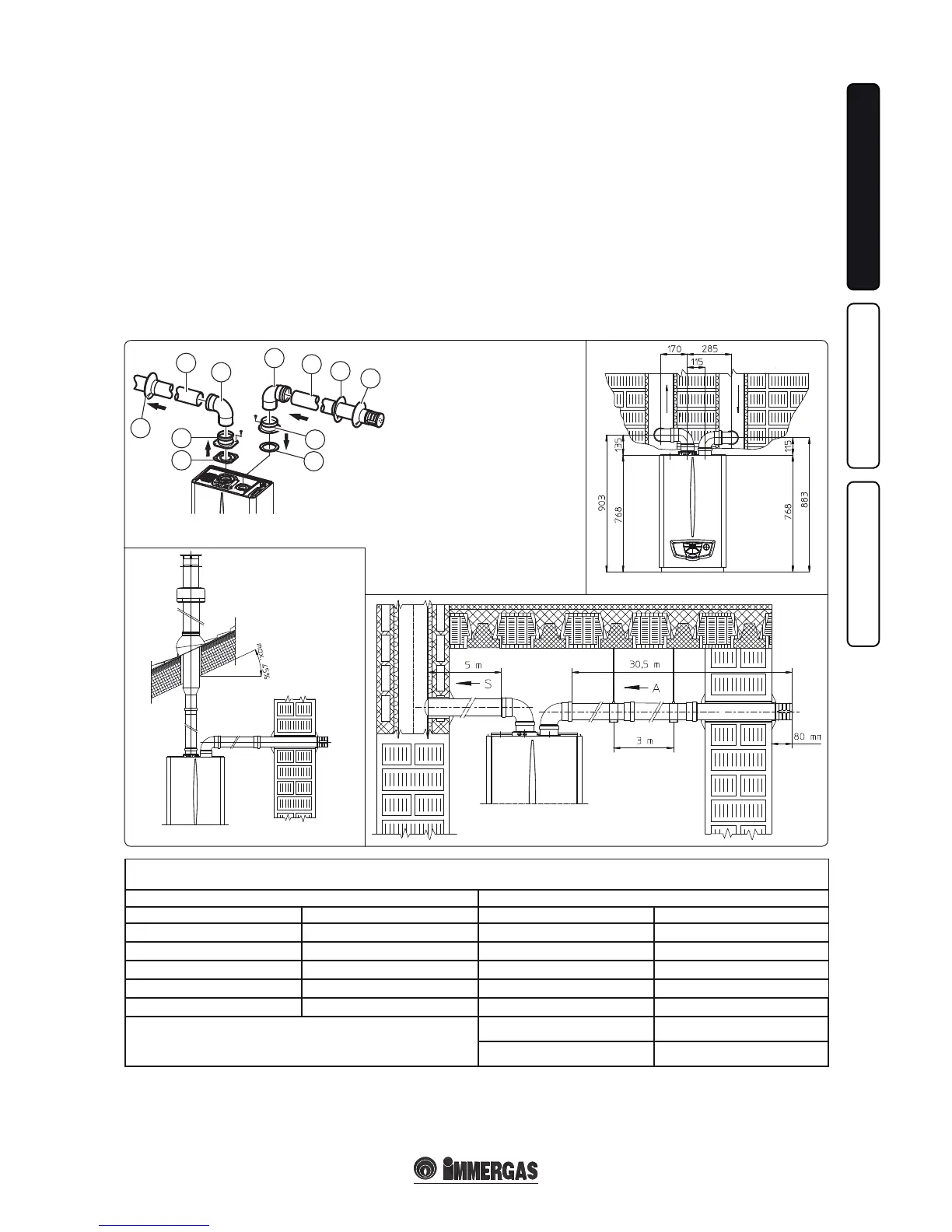

• Coupling of extension pipes and elbows. To

install snap-t extensions with other elements

of the fume extraction elements assembly, pro-

ceed as follows: Install the pipe or elbow with

the male side (smooth) on the female section

(with lip seal) to the end stop on the previously

installed element. is will ensure sealing and

joining of the elements correctly.

• Figure 1-27 shows the configuration with

vertical exhaust and horizontal intake.

• Installation clearances. Figure 1-26 gives the

min. installation space dimensions of the Ø

80/80 separator terminal kit in limited condi-

tions.

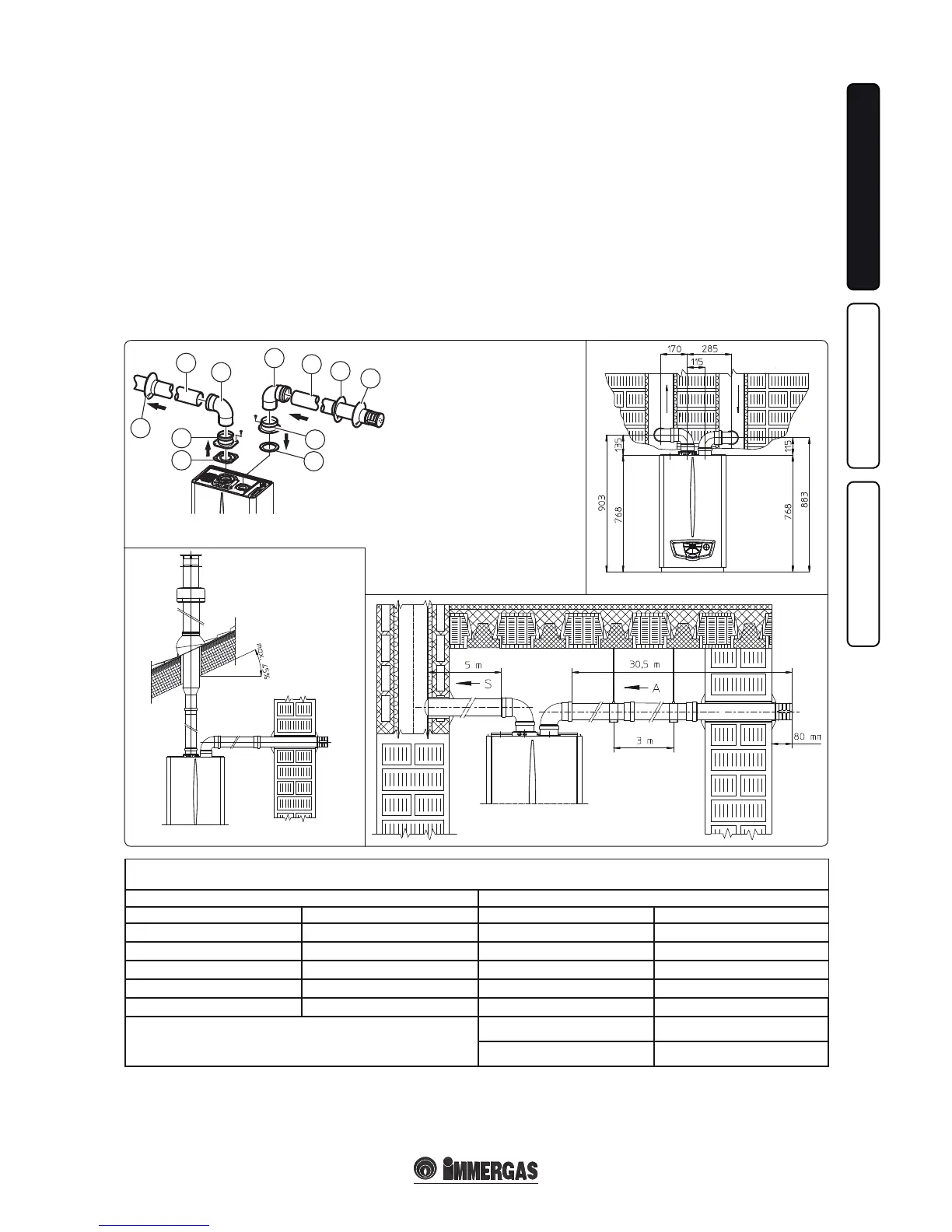

• Extensions for the separator kit Ø 80/80. e

max. vertical straight length (without bends)

that can be used for Ø 80 intake and exhaust

pipes is 41 metres of which 40 intake and 1

exhaust. The total length corresponds to a

resistance factor of 100. e total usable length

obtained by adding the length of the intake and

exhaust pipes Ø 80 must not exceed the values

stated in the following table. If mixed accessori-

es or components are used (e.g. changing from

a separator Ø 80/80 to a concentric pipe), the

maximum extension can be calculated by using

a resistance factor for each component or the

equivalent length. e sum of these resistance

factors must not exceed 100.

• Temperature loss in fume ducts. To prevent

problems of fume condensate in the exhaust

pipe Ø 80, due to fume cooling through the

wall, the length of the pipe must be limited to

just 5 m. Fig. 1-28). If longer distances must

be covered, use Ø 80 pipes with insulation (see

insulated separator kit Ø 80/80 chapter).

N.B.: when installing the Ø 80 ducts, a section

clamp with pin must be installed every 3 metres.

* e air intake pipe can be increased to 2.5

metres if the exhaust bend is eliminated, 2

metres if the air intake bend is eliminated, and

4.5 metres eliminating both bends.

e kit includes:

N°1 - Exhaust gasket (1)

N°1 - Female intake ange (3)

N°1 - Flange gasket (2)

N°1 - Female exhaust ange (4)

N°2 - 90° bend Ø 80 (5)

N°1 - Intake terminal Ø 80 (6)

N°2 - Internal white wall sealing plates (7)

N°1 - External grey wall sealing ring (8)

N°1 - Exhaust pipe Ø 80 (9)

Maximum usable length

(including intake terminal with grill and two 90° bends)

NON INSULATED PIPE INSULATED PIPE

Exhaust (m) Intake (m) Exhaust (m) Intake (m)

1 36,0* 6 29,5*

2 34,5* 7 28,0*

3 33,0* 8 26,5*

4 32,0* 9 25,5*

5 30,5* 10 24,0*

* e air intake pipe can be increased to 2.5 metres if the exhaust bend is

eliminated, 2 metres if the air intake bend is eliminated, and 4.5 metres

eliminating both bends.

11 22,5*

12 21,5*

Important: the boiler was designed to evacuate

combustion product up to a maximum extension

of 27 linear m to the exhaust, with 1 m plus 90°

bend at intake. If installation requires an exten-

sion of the ue ttings up to the exhaust that

exceeds the 12 m recommended, it is necessary

to properly consider the possibility that conden-

sation may form inside the duct and therefore

Immergas “Serie Blu” insulated ue ttings, or

other ue ttings with similar characteristics,

should be used.

Loading...

Loading...