17

A

B

C

D

INSTALLERUSER

MAINTENANCE TECHNICIAN

Head (m H

2

O)

Flow rate (l/h)

Head (kPa)

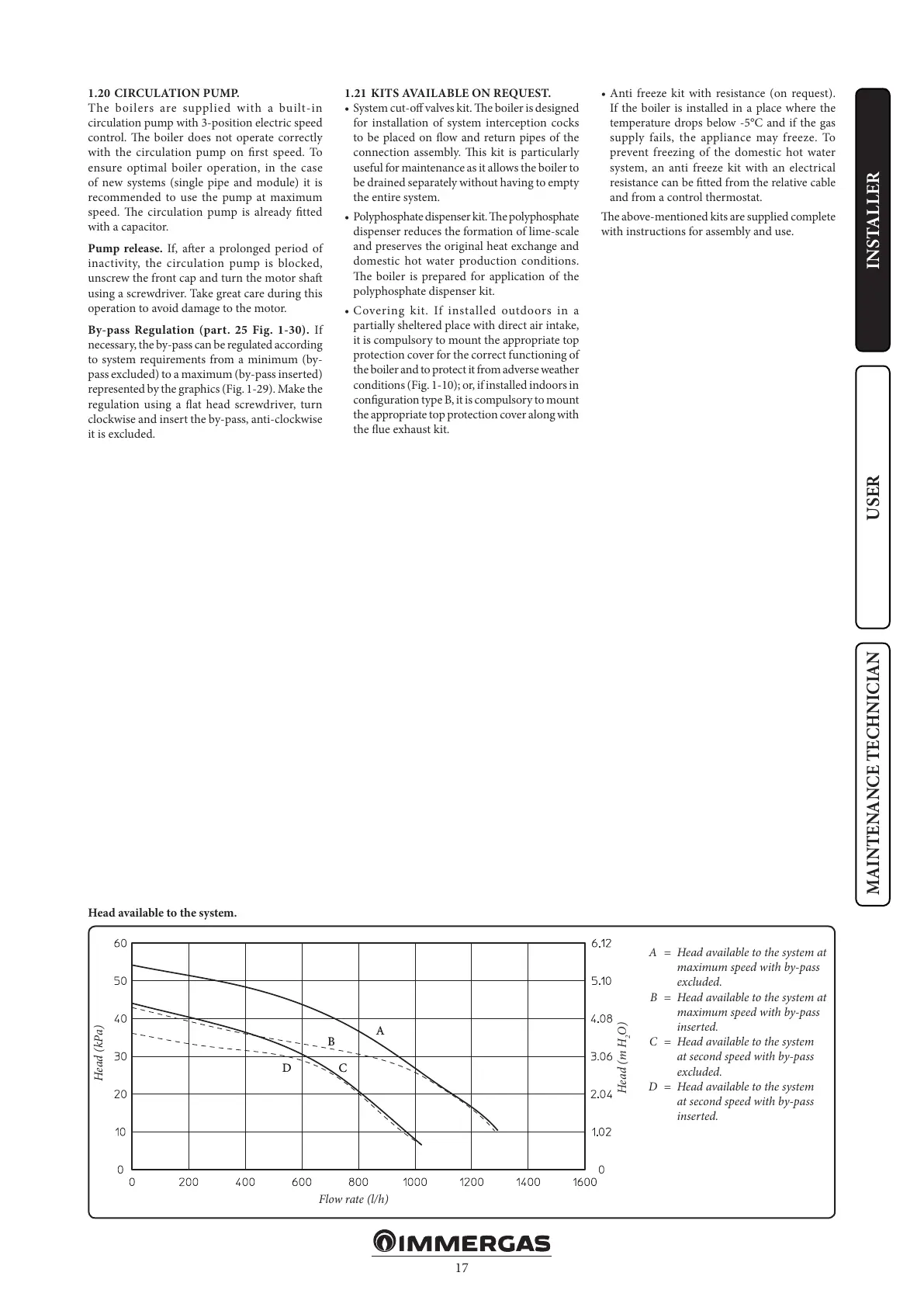

Head available to the system.

A = Head available to the system at

maximum speed with by-pass

excluded.

B = Head available to the system at

maximum speed with by-pass

inserted.

C = Head available to the system

at second speed with by-pass

excluded.

D = Head available to the system

at second speed with by-pass

inserted.

A

B

C

D

1.20 CIRCULATION PUMP.

The boilers are supplied with a built-in

circulation pump with 3-position electric speed

control. e boiler does not operate correctly

with the circulation pump on rst speed. To

ensure optimal boiler operation, in the case

of new systems (single pipe and module) it is

recommended to use the pump at maximum

speed. e circulation pump is already tted

with a capacitor.

Pump release. If, aer a prolonged period of

inactivity, the circulation pump is blocked,

unscrew the front cap and turn the motor sha

using a screwdriver. Take great care during this

operation to avoid damage to the motor.

By-pass Regulation (part. 25 Fig. 1-30). If

necessary, the by-pass can be regulated according

to system requirements from a minimum (by-

pass excluded) to a maximum (by-pass inserted)

represented by the graphics (Fig. 1-29). Make the

regulation using a at head screwdriver, turn

clockwise and insert the by-pass, anti-clockwise

it is excluded.

1.21 KITS AVAILABLE ON REQUEST.

• System cut-o valves kit. e boiler is designed

for installation of system interception cocks

to be placed on ow and return pipes of the

connection assembly. is kit is particularly

useful for maintenance as it allows the boiler to

be drained separately without having to empty

the entire system.

• Polyphosphate dispenser kit. e polyphosphate

dispenser reduces the formation of lime-scale

and preserves the original heat exchange and

domestic hot water production conditions.

e boiler is prepared for application of the

polyphosphate dispenser kit.

• Covering kit. If installed outdoors in a

partially sheltered place with direct air intake,

it is compulsory to mount the appropriate top

protection cover for the correct functioning of

the boiler and to protect it from adverse weather

conditions (Fig. 1-10); or, if installed indoors in

conguration type B, it is compulsory to mount

the appropriate top protection cover along with

the ue exhaust kit.

• Anti freeze kit with resistance (on request).

If the boiler is installed in a place where the

temperature drops below -5°C and if the gas

supply fails, the appliance may freeze. To

prevent freezing of the domestic hot water

system, an anti freeze kit with an electrical

resistance can be tted from the relative cable

and from a control thermostat.

e above-mentioned kits are supplied complete

with instructions for assembly and use.

Loading...

Loading...