1.5 Air intake and fume exhaust terminal installation.

Immergas supplies various solutions separately from the

boilers for the installation of air intake and fume exhaust

terminals necessary for boiler operation.

Important: the boiler must only be installed together with

an original Immergas “Green Range” air intake and fume

extraction system in plastic, as required by current regula-

tions. is system is identiable by a special distinctive

marking giving the note: “for condensing boilers only”.

Important:

- for C1 type installation with doubled terminals, these must

be installed inside a 50 cm square perimeter;

- for C3 type installation the terminals must be installed

inside a 50 cm square perimeter and the distance between

the two levels of the openings must be less than 50 cm;

- for C5 type installation the two terminals must not be

installed on opposite walls of the building.

• Resistance factors and equivalent lengths. Each fume ex-

traction system component has a resistance factor obtained

from preliminary tests and specied in the table below. e

resistance factor of the single component does not depend

on the type of boiler on which it is installed and is a dimen-

sional value. It is based on the temperature of uids passing

through the ducts and therefore varies according to use in

air intake or fume exhaust. Each single component has a

resistance corresponding to a certain length in metres of

pipe of the same diameter: the so-called equivalent length.

All boilers have an experimentally obtainable maximum

Resistance Factor equal to 100. e maximum permissible

resistance factor corresponds to the resistance detected with

the maximum permissible pipe length with each type of

Terminal Kit. is information enables calculations for

verifying the possibility of executing a wide range of fume

extraction system congurations.

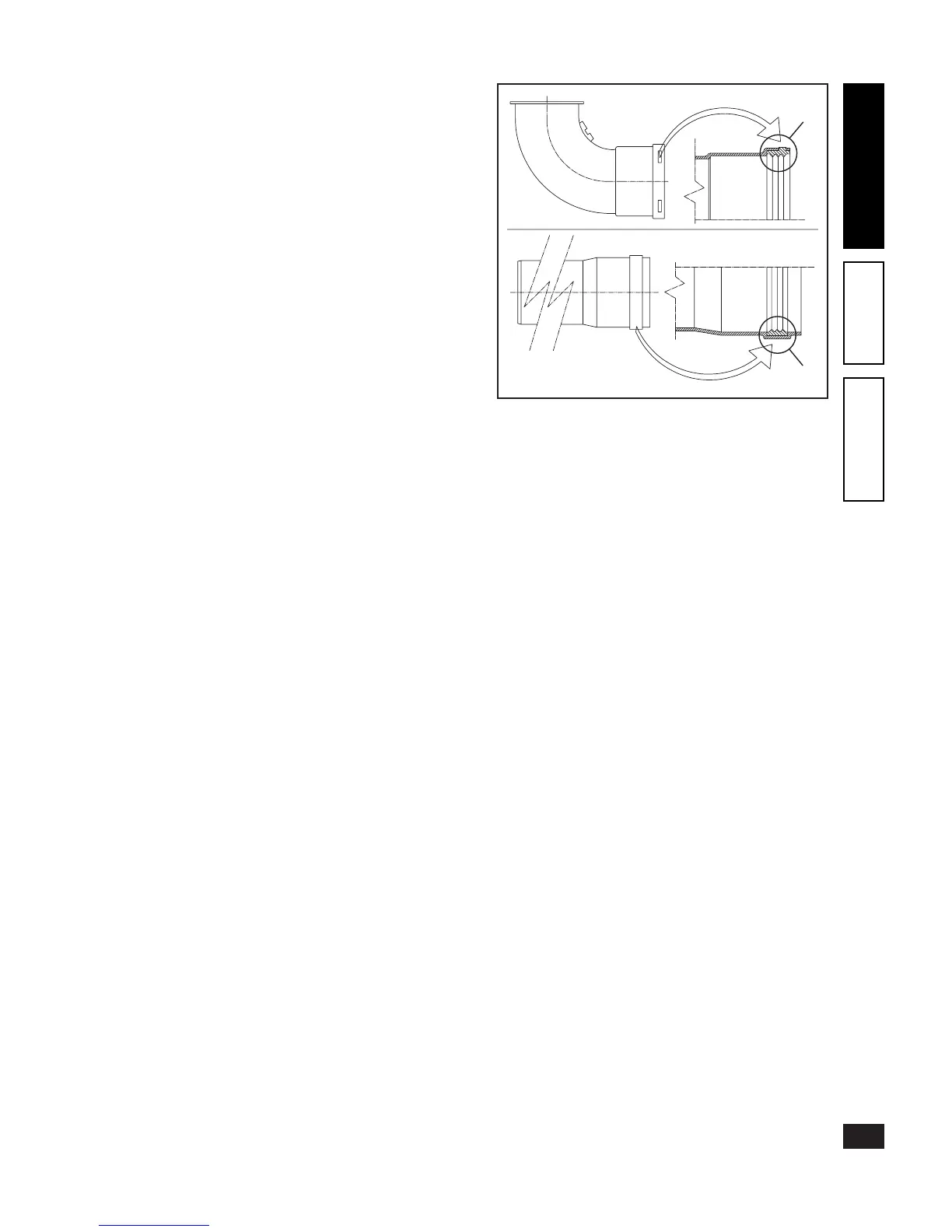

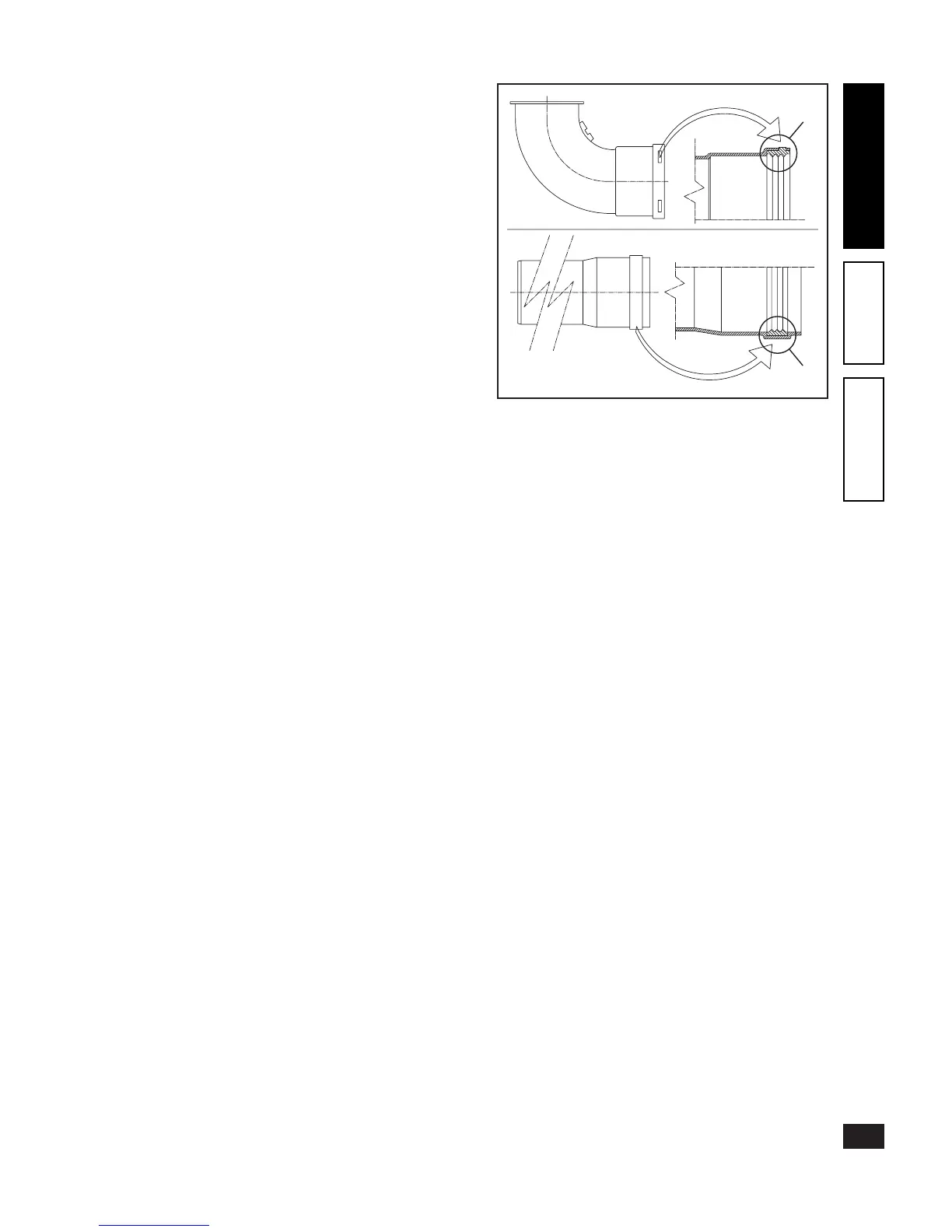

Positioning of seals (black) for “Green Range” fume ex-

traction system. Make sure to correctly place the seal (for

bends or extensions) as shown in the gure:

- seal (A) with notches, to be used for bends;

- seal (B) without notches, to be used for extensions;

N.B.: if the lubrication of the components (already carried

out by the manufacturer) is insucient, remove the residual

lubricant using a dry rag, then cover the parts with normal

or industrial talc to facilitate coupling.

(A)

(B)

Loading...

Loading...