9

STV75 ed 01/08 VICTRIX 75

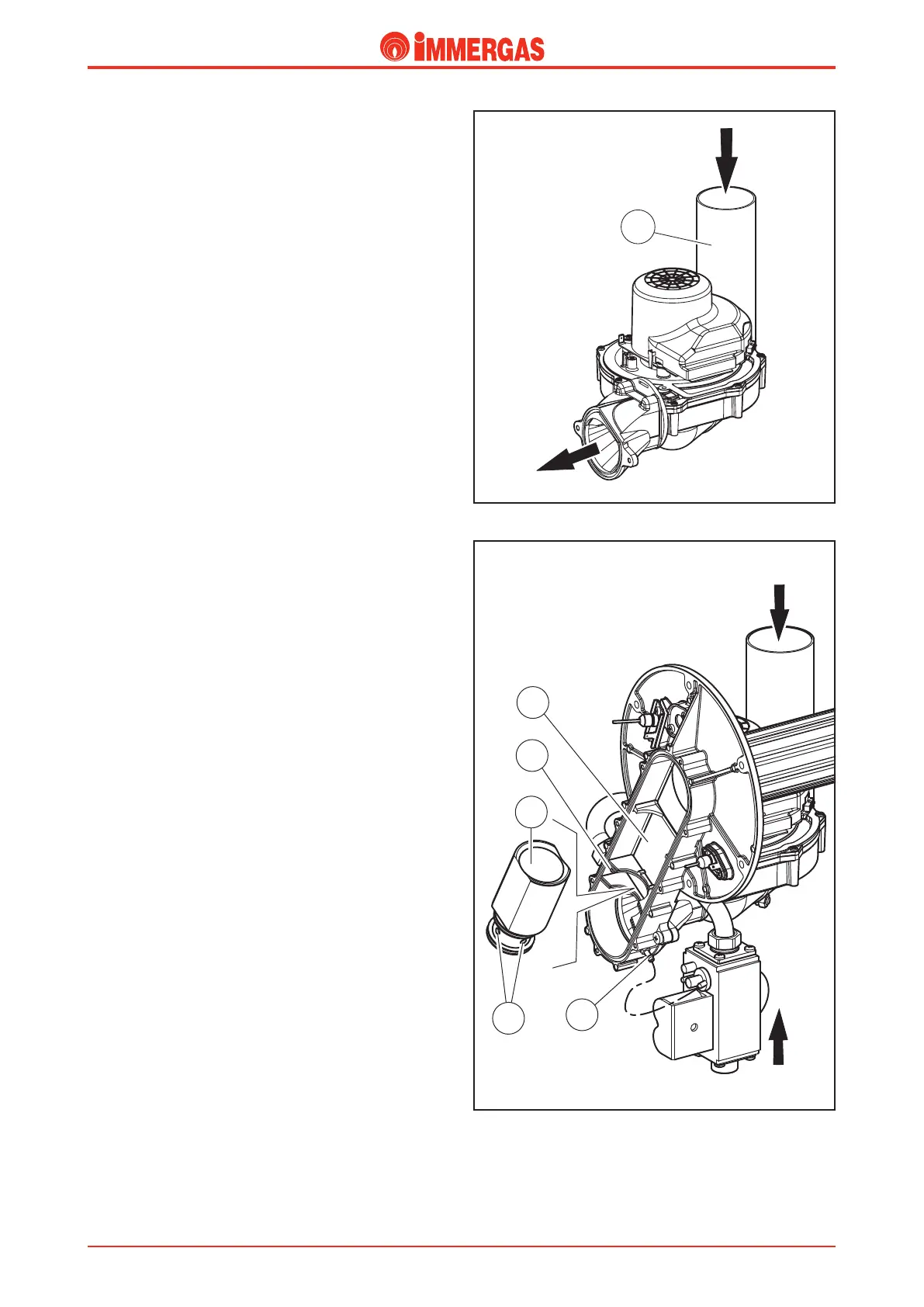

Fan.

is operates upstream from the combustion chamber and it

is physically positioned at the bottom of said chamber.

e fan is powered by mains voltage (230 V AC) and is control-

led by the integrated board by a positive square wave signal

with a variable ON-OFF ratio (duty-cycle).

Its speed is adjusted (from about 1500 to about 5500 rpm) ac-

cording to the output required and is controlled by means of

a Hall eect sensor which reads the rpm.

e fan extracts the combustion air from the top of the draught

diverter through a plastic pipe (1) that helps reduce noise and

optimises burner ignition.

Variations in the ow of air entering the mixing duct results

in a variation in the pressure (P1) signal at the inlet of the

Venturi pipe and enables the pneumatic valve to regulate

exiting gas pressure.

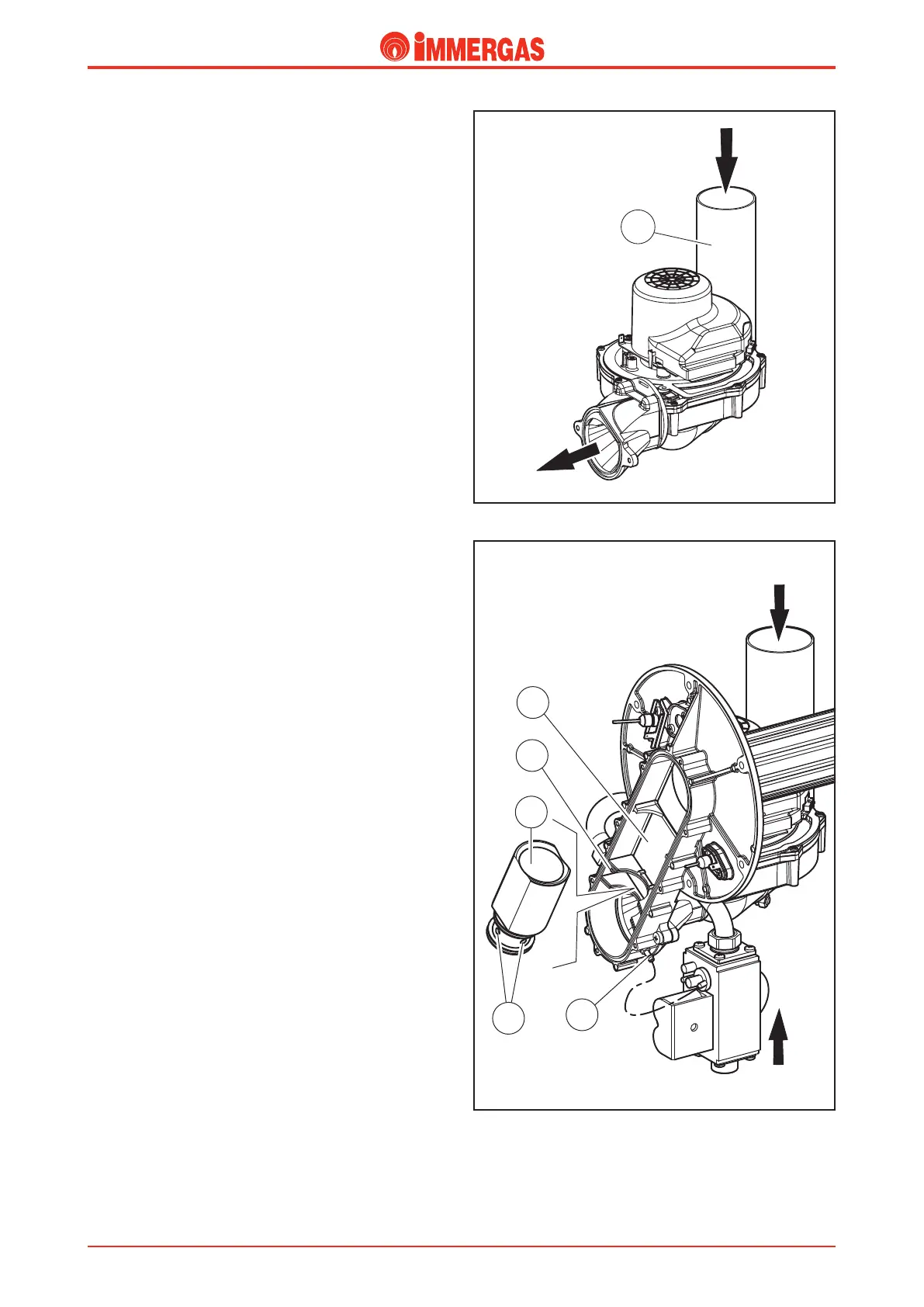

Venturi.

e Venturi pipe (1) is tted in a sealed duct (4) inside which

the combustion air and gas are mixed.

e air is driven to the bottom of the duct by the fan, while

the exiting gas from the valve is injected at the Venturi pipe

(1) inlet by a nozzle (2).

e transit of air in the pipe creates vacuum (“Venturi eect”)

which, through the 4 holes (3) in the base, “drags” the gas

inside and mixes it with the air.

e nozzle (2) diers in diameter according to whether natural

gas or LPG is used; in fact working with both gases at a more or

less constant pressure, its section determines correct gas ow.

At the end of the Venturi pipe is a pressure pick-up point where

the input signal (P1) is read.

is signal is conveyed to the pneumatic valve regulating the

gas pressure via a silicone pipe.

Technical Documentation

Technical Documentation

Loading...

Loading...