1

4

7

9

5

5

6

7

8

3

2

S

A

C

53

* - C

83

* per completare la congurazione C

53

prevedere anche un terminale di scarico a

tetto. Non è ammessa la congurazione su pareti opposte all'edicio.

27

2625

INSTALLERUSERMAINTENANCE TECHNICIAN

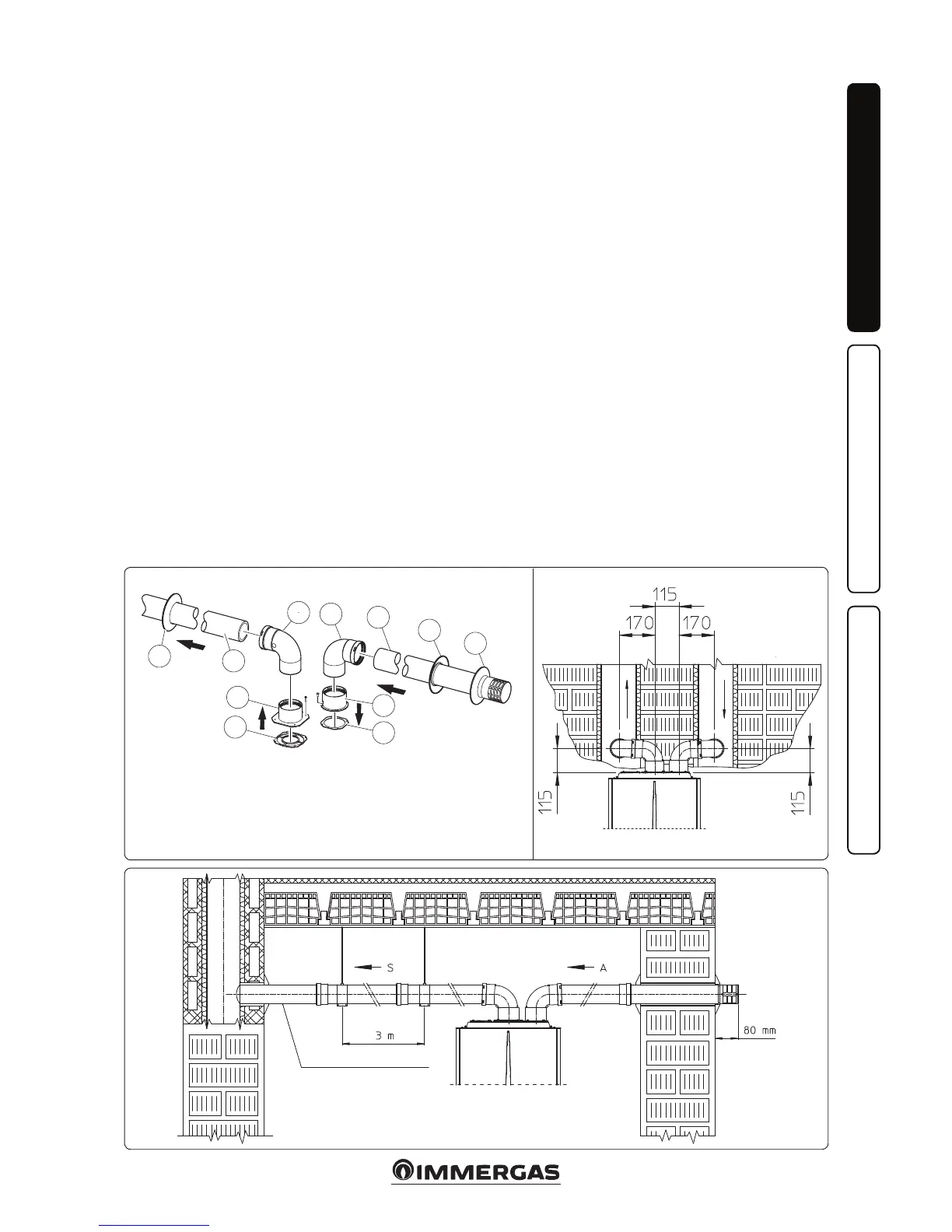

e kit includes:

N° 1 - Exhaust gasket (1)

N° 1 - Flange gasket (2)

N° 1 - Female intake ange (3)

N° 1 - Female exhaust ange (4)

N° 2 - Bend 90° Ø 80 (5)

N° 1 - Intake terminal Ø 80 (6)

N° 2 - Internal wall sealing plates (7)

N° 1 - External wall sealing plate (8)

N° 1 - Exhaust pipe Ø 80 (9)

1.17 SEPARATOR KIT INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

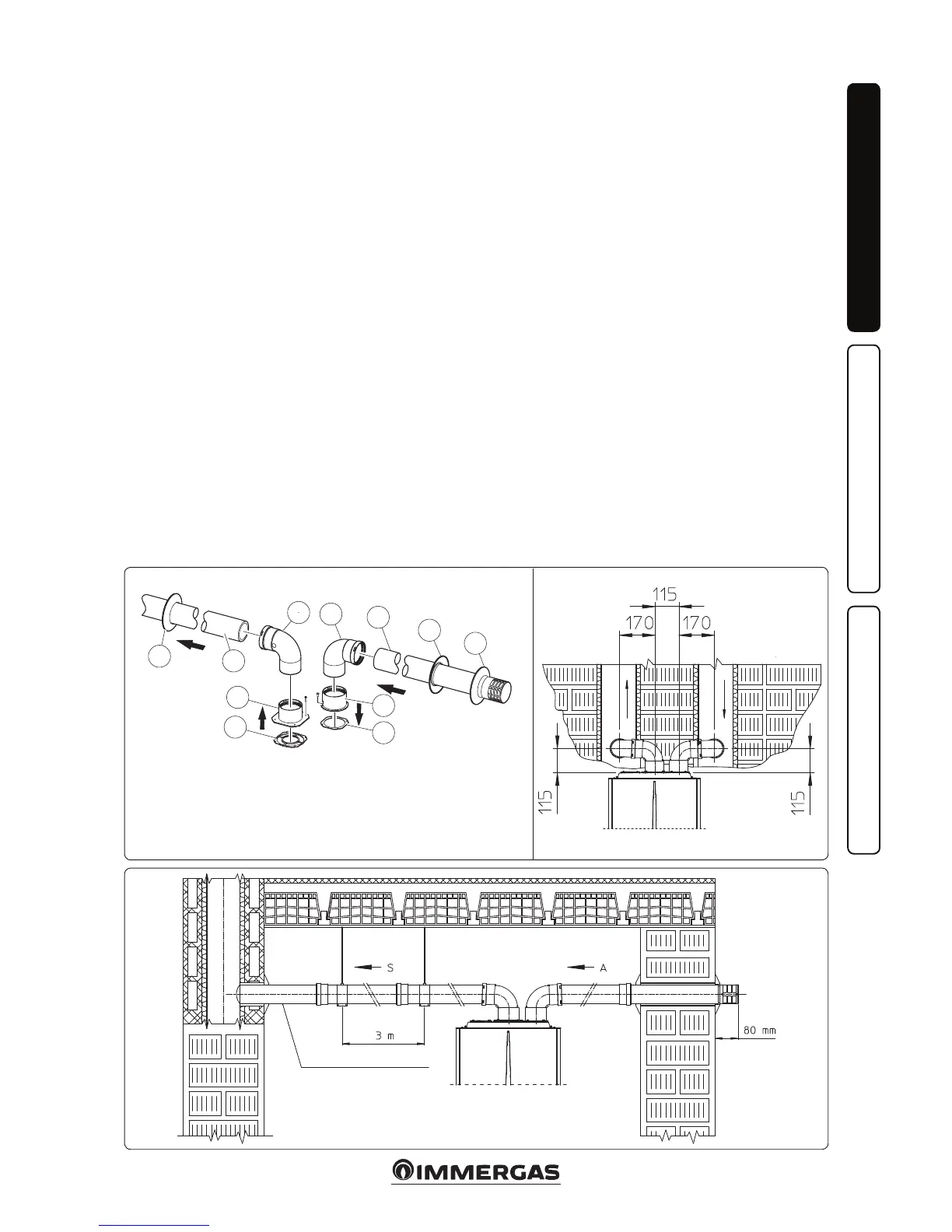

Separator kit Ø 80/80. is kit allows air to come

in from outside the building and the exhaust to

exit from the chimney, ue or intubated duct

through divided ue exhaust and air intake pipes.

Combustion products are expelled from pipe (S)

(in plastic, so as to resist acid condensate). Air is

taken in through duct (A) for combustion (this

is also in plastic). e intake pipe (A) can be

installed either on the right or le hand side of

the central exhaust pipe (S). Both ducts can be

routed in any direction.

• Kit assembly (Fig. 25): install ange (4) on the

central hole of the boiler, positioning gasket

(1) with the circular projections downwards

in contact with the boiler ange, and tighten

using the hex screws with at tip contained

in the kit. Remove the at ange present in

the lateral hole with respect to the central one

(according to needs) and replace it with the

ange (3), positioning the gasket (2) already

present in the boiler and tighten using the

supplied self-threading screws. Fit the male side

(smooth) to the bends (5) in the female side of

the anges (3 and 4). Fit the intake terminal (6)

with the male side (smooth) in the female side

of the bend (5) up to the end stop, ensuring that

the internal and external wall sealing plates are

tted. Fit the exhaust pipe (9) with the male

end (smooth) to the female end of the bend

(5) up to the end stop; making sure that the

internal wall sealing plate has been tted, this

will ensure sealing and joining of the elements

making up the kit.

• Installation clearances (Fig. 26). e minimum

installation clearance measurements of the Ø

80/80 separator terminal kit have been stated

in some limit conditions.

• Extensions for separator kit Ø 80/80. The

maximum vertical straight length (without

bends) that can be used for Ø 80 intake and

exhaust pipes is 41 metres, regardless from

whether they are used for intake or exhaust.

e maximum horizontal straight length (with

bend in suction and in exhaust) that can be

used for Ø 80 intake and exhaust pipes is 36

metres, regardless from whether they are used

for intake or exhaust. Please note the type of

installation must be done with a natural

draught ue.

N.B.: to favour the removal of possible conden-

sate forming in the exhaust pipe, tilt the pipes

towards the boiler with a minimum slope of

1.5% (Fig. 27).

C

43

Minimum slope 1.5%

Loading...

Loading...