16

STZSkW ed 12/07 ZEUS Superior kW

Technical DocumentationTechnical Documentation

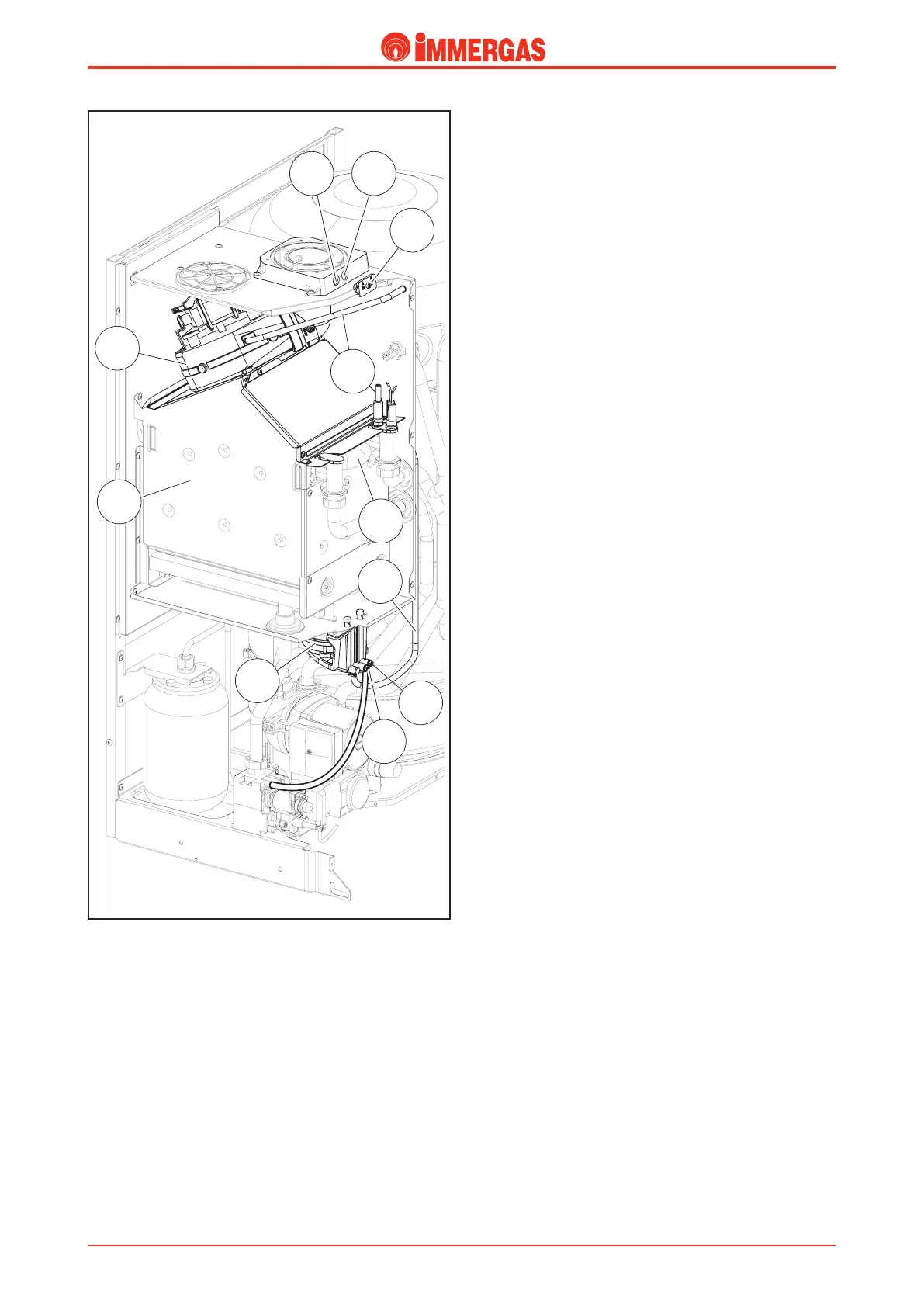

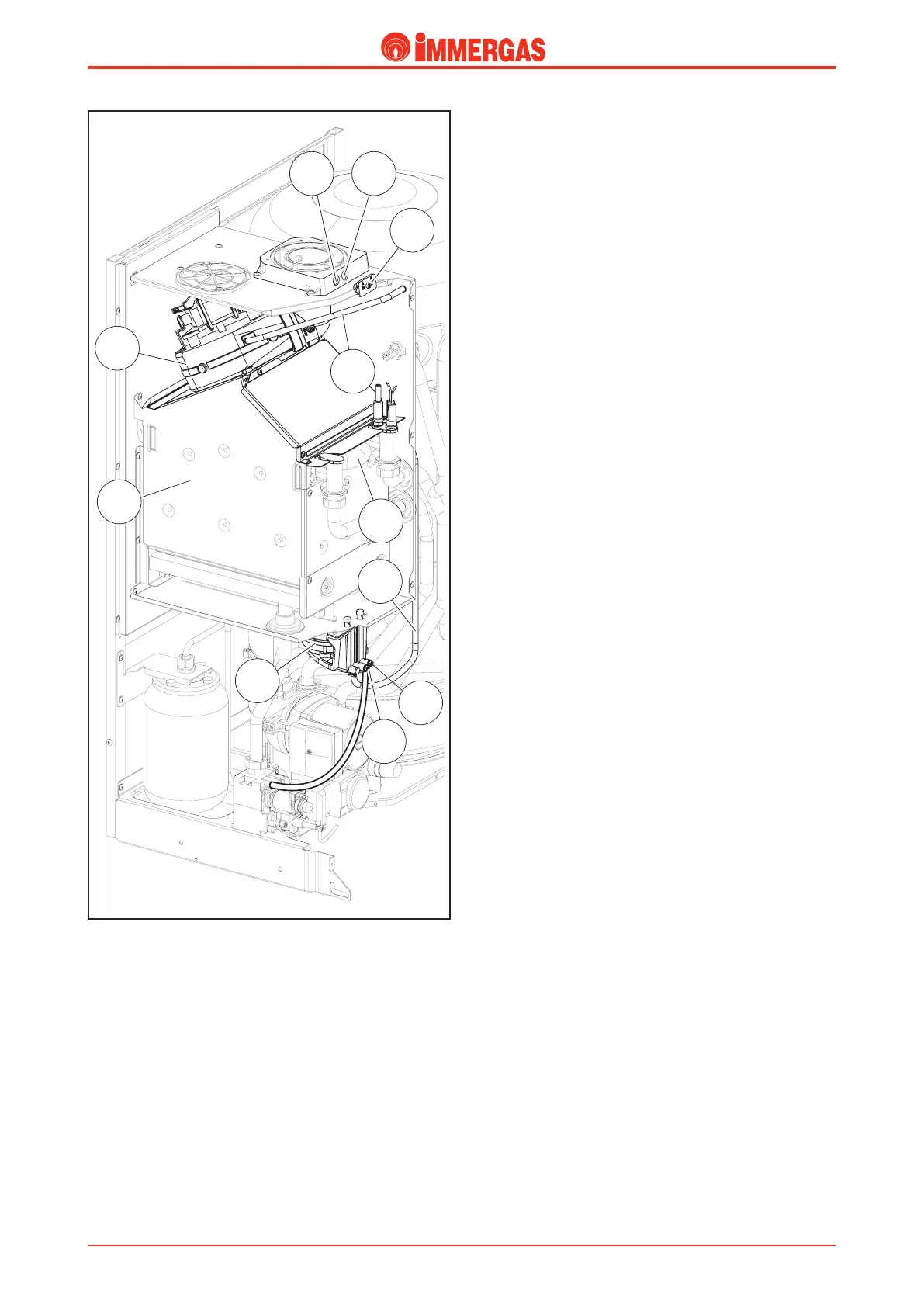

pipe (11) which is connected to the negative pressure point

of the ue pressure switch (6) and to the pressure point on

the fan.

e positive pressure point (10) is connected directly to the

inside of the sealed chamber.

Flue ow meter (6).

It is positioned in the lower external part of the sealed chamber

and detects, through the relevant point, the pressure dierence

between the inside of the fan (negative signal) and the inside

of the sealed chamber (positive signal).

e signal generated by the ue ow meter (6) is managed by

the circuit board in order to adjust fan speed (5), in a way to

maintain the pressure dierence constant at a value between

60 and 90 Pascal (between 6.1 and 9.2 mm. H

2

O), which can

be measured by the relevant pressure sockets (9-10).

When the pressure reaches the value set on the integrated

P.C.B. the burner can be ignited.

Fan (5).

e ue discharging fan operates downstream from the com-

bustion chamber and is physically installed on the upper part

of the ue hood (4) from where it extracts ue and directs

them to the ue system ducts the boiler is connected to. At

the same time, it ensures combustion air ow into the sealed

chamber.

e fan is controlled by the integrated P.C.B. and its function

essentially follows the burner operation.

Air/ue sample points (7-8).

ere are two sample points on the upper side of the sealed

chamber (they are accessible from the front), which can be used

to take samples of combustion air (7) and ue (8).

e two sample points are closed by one single plastic plug.

(13).

Flue pressure switch signal pressure points

(9-10).

In the lower external part of the sealed chamber, there are two

pres sure points, which can be used to verify the signal on either

end of the ue pressure switch (6).

e negative pressure point (9) is connected to a silicone

Loading...

Loading...