17

STZSkW ed 12/07 ZEUS Superior kW

Technical Documentation

Technical Documentation

Intake and exhaust systems.

(see intake and exhaust terminals instructions).

e ZEUS Superior kW boiler is arranged for connection to

the appropriate push-tting intake/exhaust pipes and can be

installed inside the home or outside the home (in a partially

protected place) in the following congurations.

Outdoors (in a partially protected place):

- sealed chamber and fan assisted with direct intake (type C)

using a compulsory upper cover kit (optional);

- with sealed chamber and forced draught (type C) using

the vertical or horizontal concentric kits, keeping the cap

mounted, without the obligation to use the upper cover

kit.

Indoors:

- open chamber and fan assisted (type B

22

) using a compulsory

upper cover kit (optional);

- sealed chamber and fan assisted (type C) using the vertical

or horizontal concentric kits or the Ø80/80 separator kit.

For that regarding the head losses relative to each accessory,

for the various combinations that can be performed, see the

instructions relative to the intake and exhaust terminals

(boiler instruction book).

e coupling of the accessories (curves, extensions, terminals)

is the push-tting type and sealing is ensured by appropriate

gaskets with silicone lip seals.

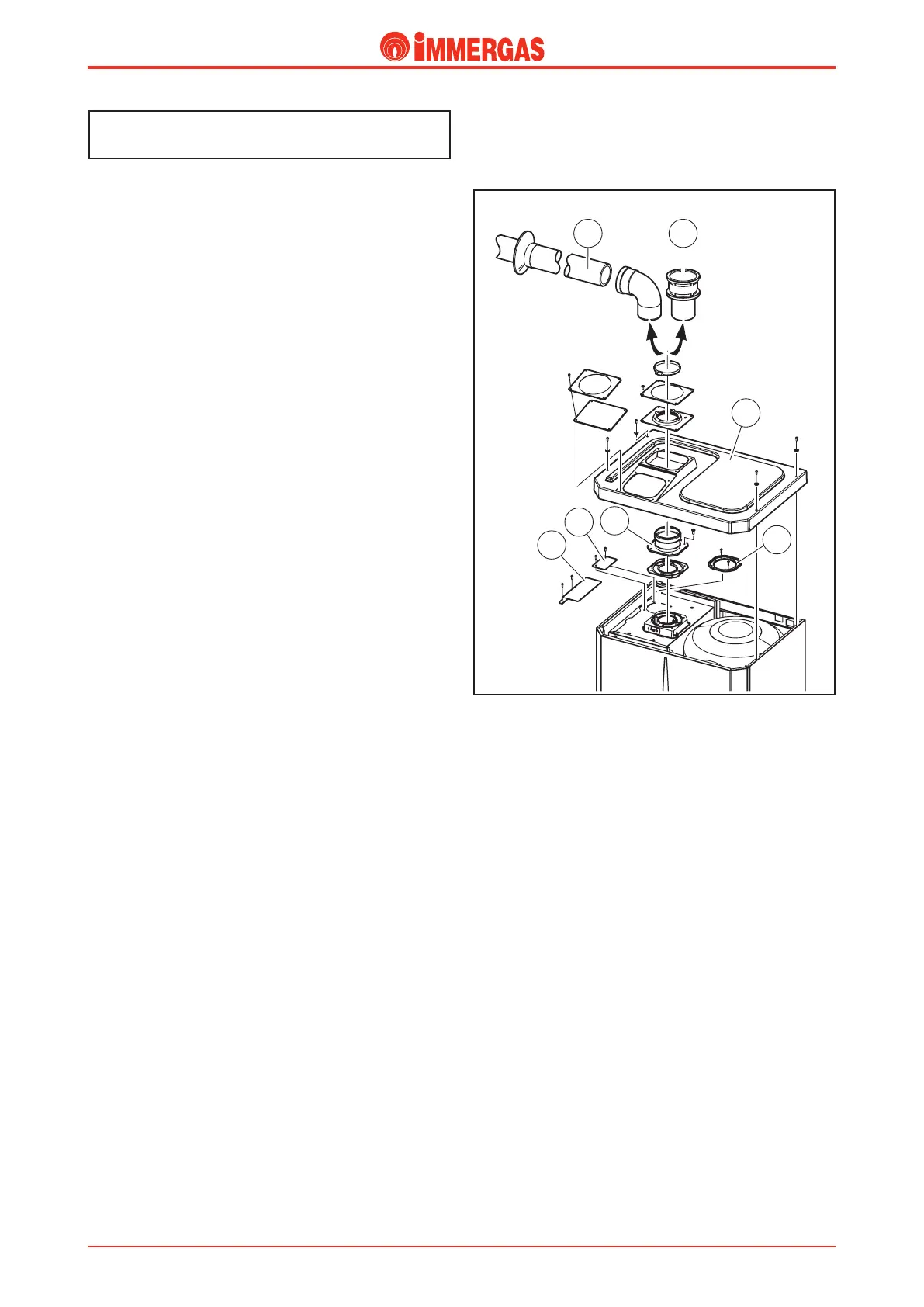

Sealed chamber and forced draught

conguration with direct intake for installation

outdoors in a partially protected place (see

gure at the side).

Using an appropriate cover (1) to be positioned on the upper

part of the sealed chamber, the boiler can be installed outdoors

in a partially protected place.

Intake.

Mounting of the cover (1) envisions the removal of the cap

(3) closing the hole present in the upper part of the sealed

chamber.

Attention:

For model 28 kW shaped sheet steel must be mounted (5)

instead of the cap (3).

For model 32 kW at sheet steel must be mounted (4) instead

of the cap (3).

e intake of combustion air takes place directly from the

environment making use of the free space between the lowerp

art of the cover (1) and the upper part of the boiler.

Exhaust.

e connection to the exhaust pipes with diameter of 80 mm

is obtained using the ange (2) used in the divided systems.

e use of the appropriate accessories aloows the horizontal

discharge (A) or vertical discharge (B).

To prevent condensate problems, the exhaust pipe must be

limited to 5 straight metres for normal pipes and 12 straight

metres for insulated pipes.

e maximum length accepted is 12 straight metres.

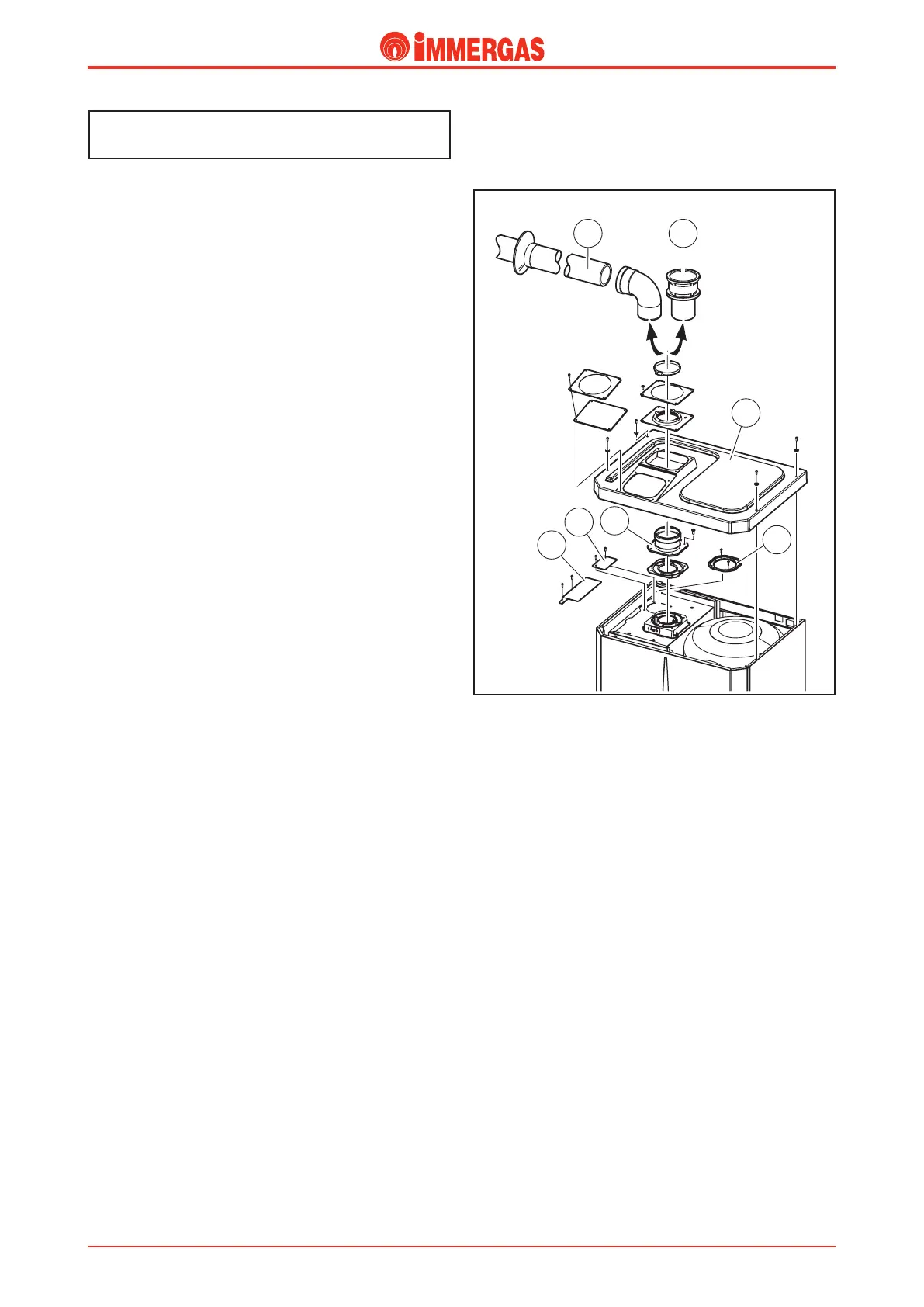

Open chamber and forced draught congura-

tion (type B

22

) for indoor installation (see gure

above).

e previously-described cover kit is used.

By removing the cap (3) present on the selaed chamber, air

intake takes place directly from the room in which the boiler

is installed.

e ues are discharged through special pipes wih a diameter

of 80 in an individual ue or directly to the outside.

Loading...

Loading...