IMO GmbH Gässlesweg 6 D-75334 Straubenhardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

15

GmbH

4.5.3 Monitor spray arm on / off

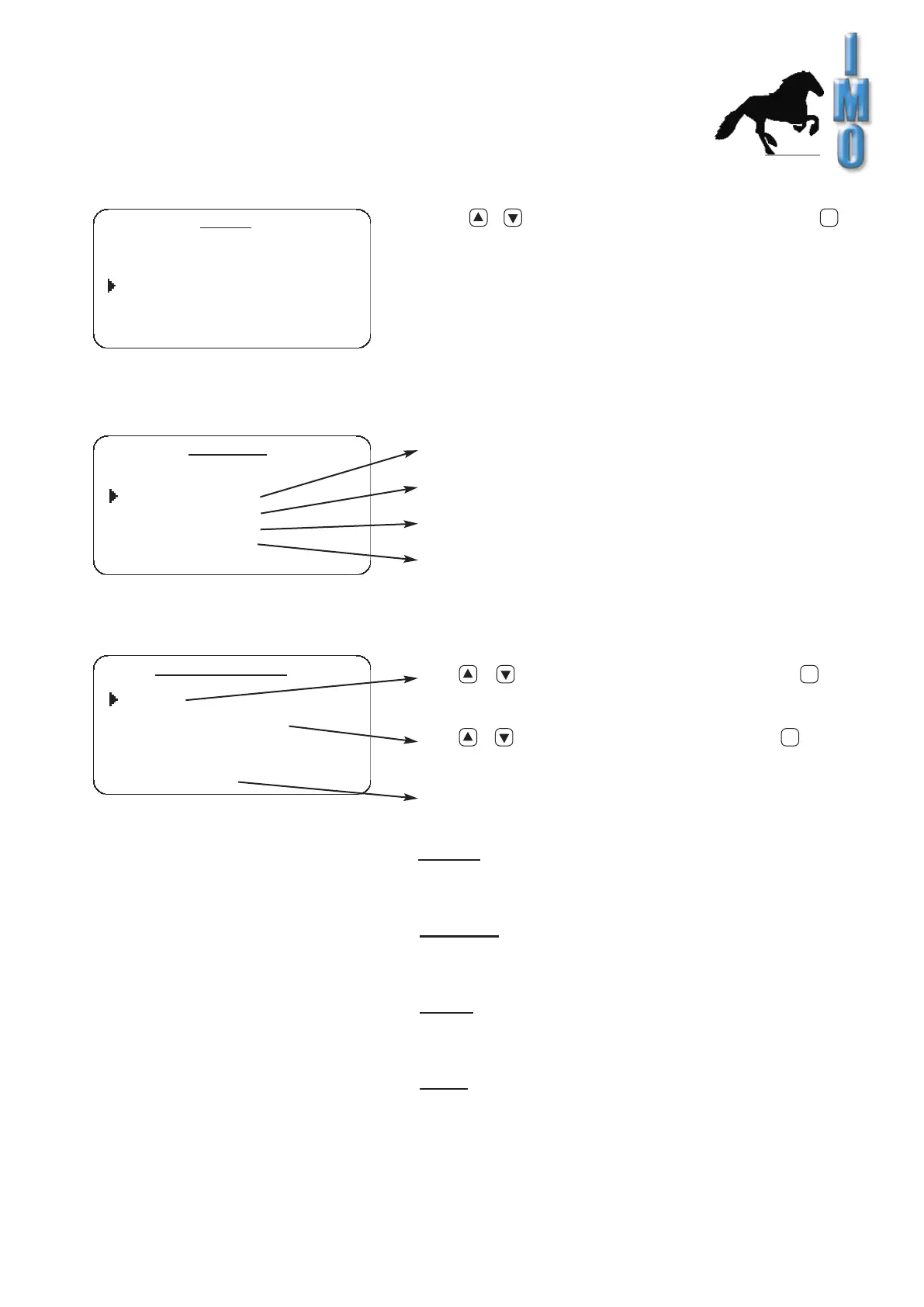

4.5.4 Detergent

4.5.4.1 List of detergent setting / altered

Select / to choose “spray-arm control” and enter

to shift.

Indication: Monitor spray arm should be regularly be activate,

otherwise the regulation of foam and resp. regocnition-blockade

of the lower spray arm don’t work.

Cleaner programs which use foaming resp. defoaming

can not be started, if the monitor spray arm is switched off.

Create or change register of detergents

Assign detergent from register to a dosing pump

Aspirate detergent manual

Indicate power off pump

Enter / to leaf through the memory and select

to choose an input.

Enter / to alter numbers and letters. Select for the

next input.

Kind of detergents in respect of his attributes will be tuned here.

Possible settings are:

foaming:

detergent produce foam, therefor it must be dosed

gradually during the cleaning process until a little “foam-carpet”

is formed.

defoaming:

detergent is for counteract foaming.

(f.e. A foaming cleaner is used at the same time)

During the cleaning process detergent will be dosed if necessary.

neutral:

detergent has no attributes as below. It will be dosed

proportional to the filled quantity of water.This proportion will be

setted by construction of the cleaning program.

empty:

register contains no detergent.

Indication: If the cleaner will be used in other cleaning

program, the modification interferes in the concerned program.

a

a

a

set up

time/date

language

Monitor spray arm: on

detergent settings

code changing

detergent

list of detergent

assign detergent

suck detergent

pump correction

list of Detergent

no.: 1

name: component A

type: neutral

Loading...

Loading...