IMO GmbH Gässlesweg 6 D-75334 Straubenhardt Tel.: 070 82 491 80 Fax: 604 36 www.imoag.com info@imoag.com

22

GmbH

5.6 Indication and maintenance

5.6.1 Foaming

ATTENTION: Heavy foaming effects an inadequately cleaning!

If a heavy foaming occurs by washing, don´t hesistate to contact us.

Heavy foaming will be recognized as follows:

Optical, after opening the door foam runs out of the machine, or a “foaming-carpet” is visible.

Acustical, unbalancedurch run (strobe idling) of the circulation pump.

5.6.2 Changing of waste water filter

5.6.3 Changing of airfilter

The wash liquor and the rinse water are passed

over the filter cartridge to filter out solid particles.

The filter cartridge must be replaced if the wastewater is not completely pumped out within the

specified time.

This is indicated by the machine.

To replace the filter cartridge, the union nut can be opened and the filter housing removed downwards.

Some water will run out; if necessary, place a bucket underneath.

If necessary, place a bucket underneath.

The pumping out can be observed through the transparent filter housing.

The air required for drying is drawn in via an airfilter (Art. No.: 7200.0408).

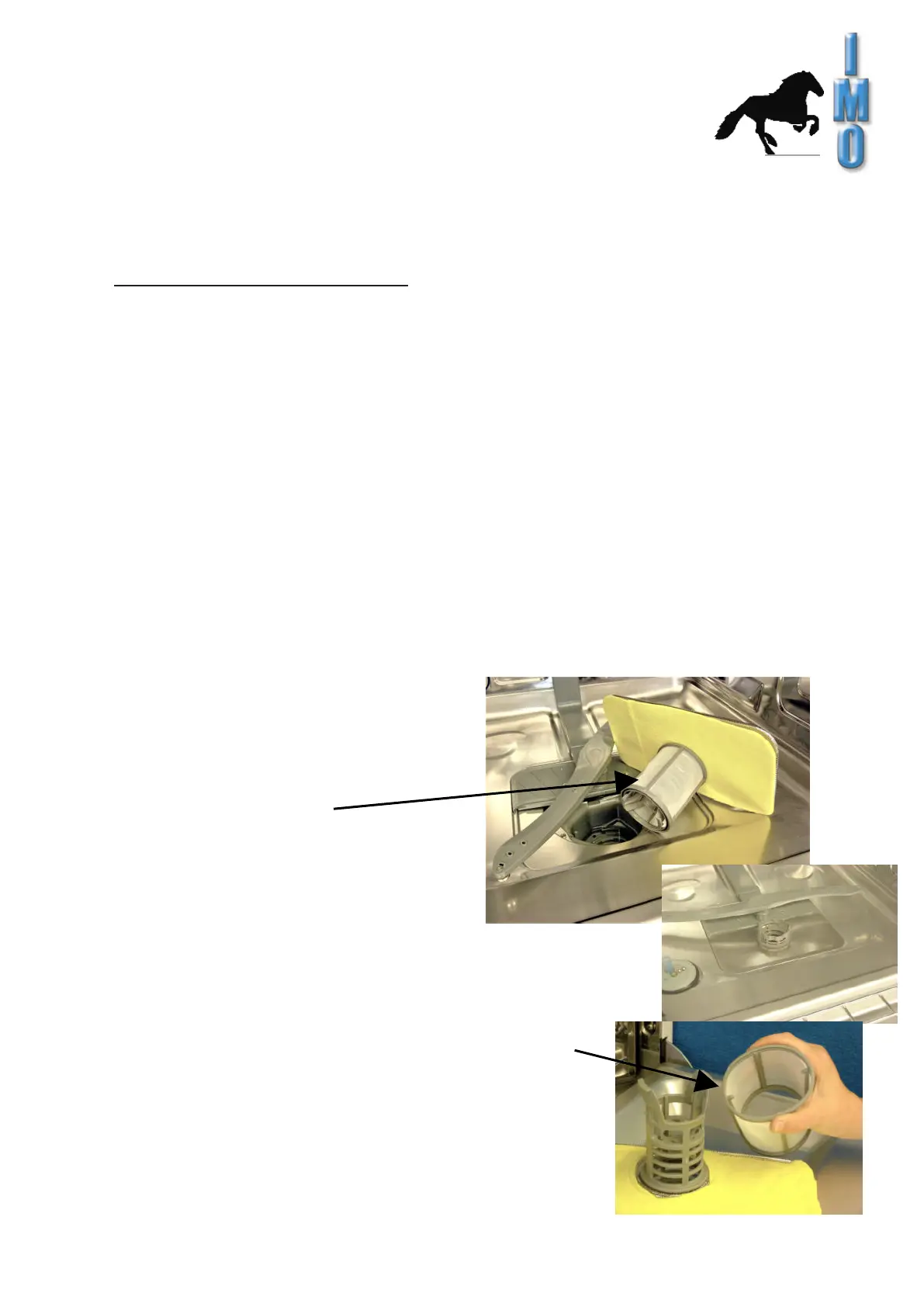

5.6.4 Cleaning the dirt trap

Clean the strainer regularly, at least

monthly, from dirt and especially from

accumulated metal chips.

The strainer, together with the

the strainer insert, by turning it counterclockwise

at the upper plastic rim.

Dirt trap

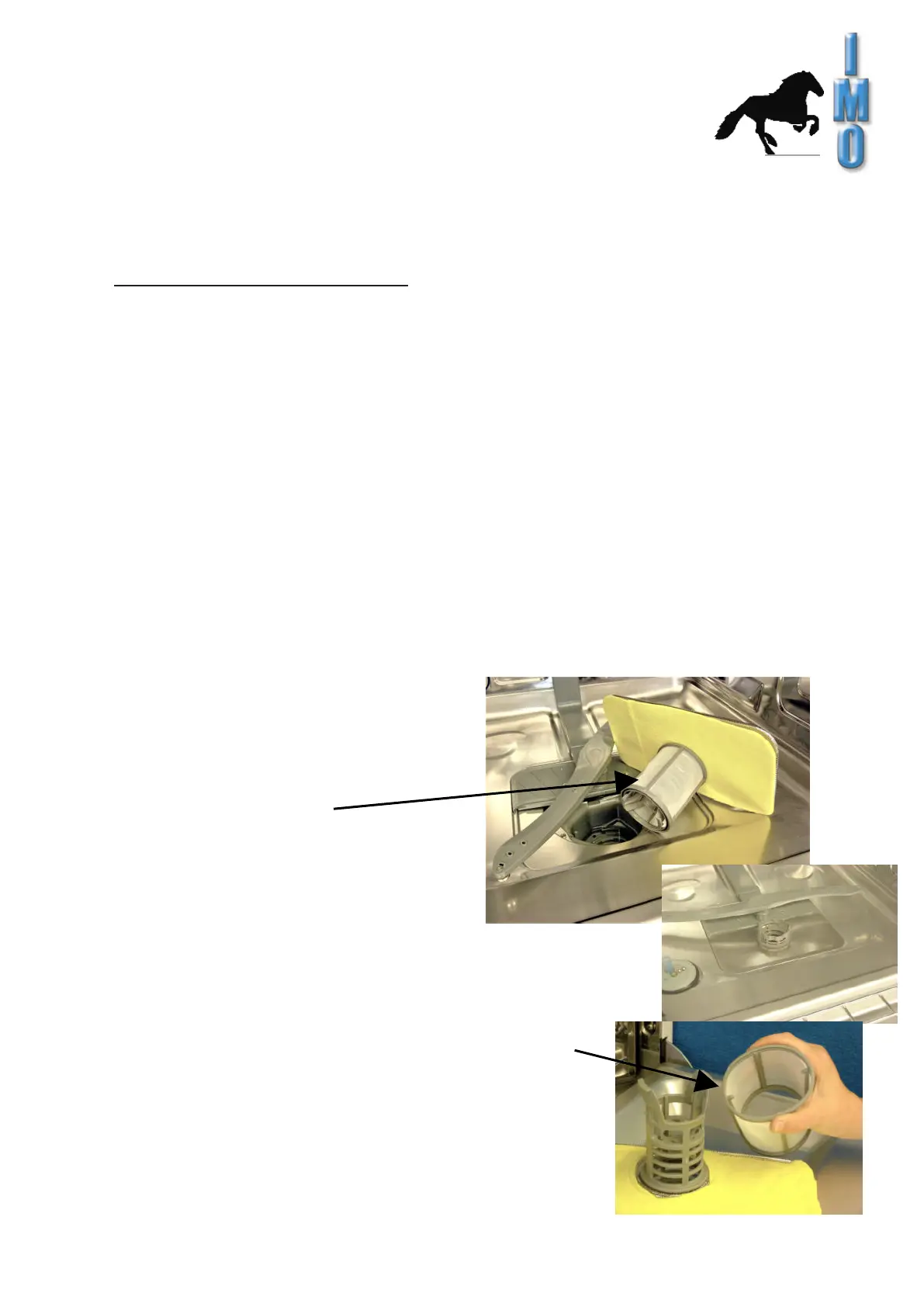

5.6.5 Cleaning the sieve insert

The filter mat can be removed after the strainer has been removed

from the strainer insert.

To remove the strainer, between its retaining hooks, slightly oval.

The filter mat can be washed in a bucket of water.

When worn, replace the filter mat.

Filter mat: Art. no.: 7000C2016

5.6.6 Replacing the spray arms

Spray arm at the bottom: Art. no.: 1800.88

Spray arm top: Art. no.: 1800.89

This filter must be checked for dirt at regular intervals and

replaced if necessary. The unit reminds you to check the filter at regular intervals by

a message on the display, to check the filter.

Filter cartridge (Art. No.: 7000C0020).

At regular intervals (approx. 4 x per year)

the sieve insert in the washroom must be removed

(by turning the plastic insert)

and the room located underneath with a

industrial vacuum cleaner from solder residues

to clean.

For optimum spraying of the wash ware, we recommend,

to replace both spray arms approx. every 200 washing cycles

Loading...

Loading...