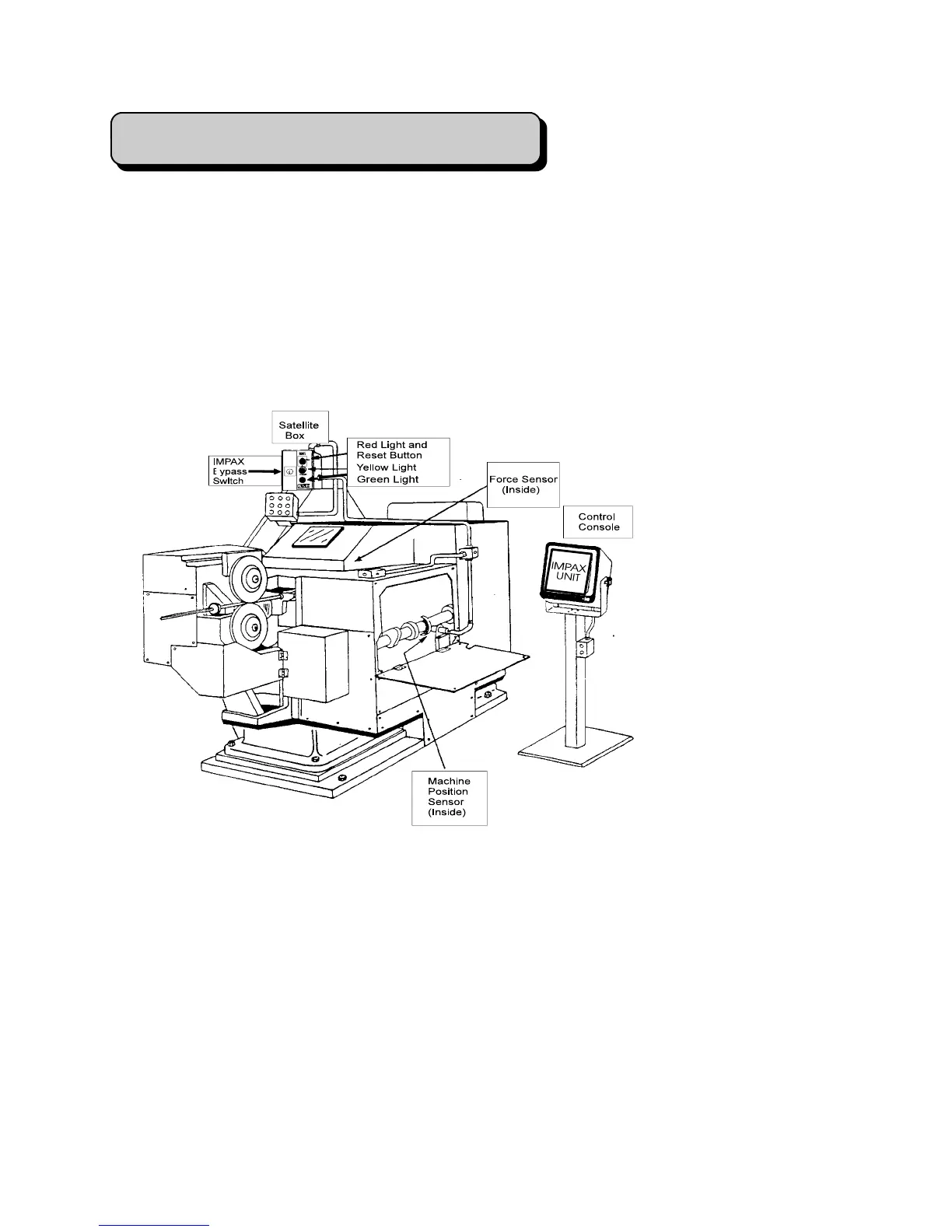

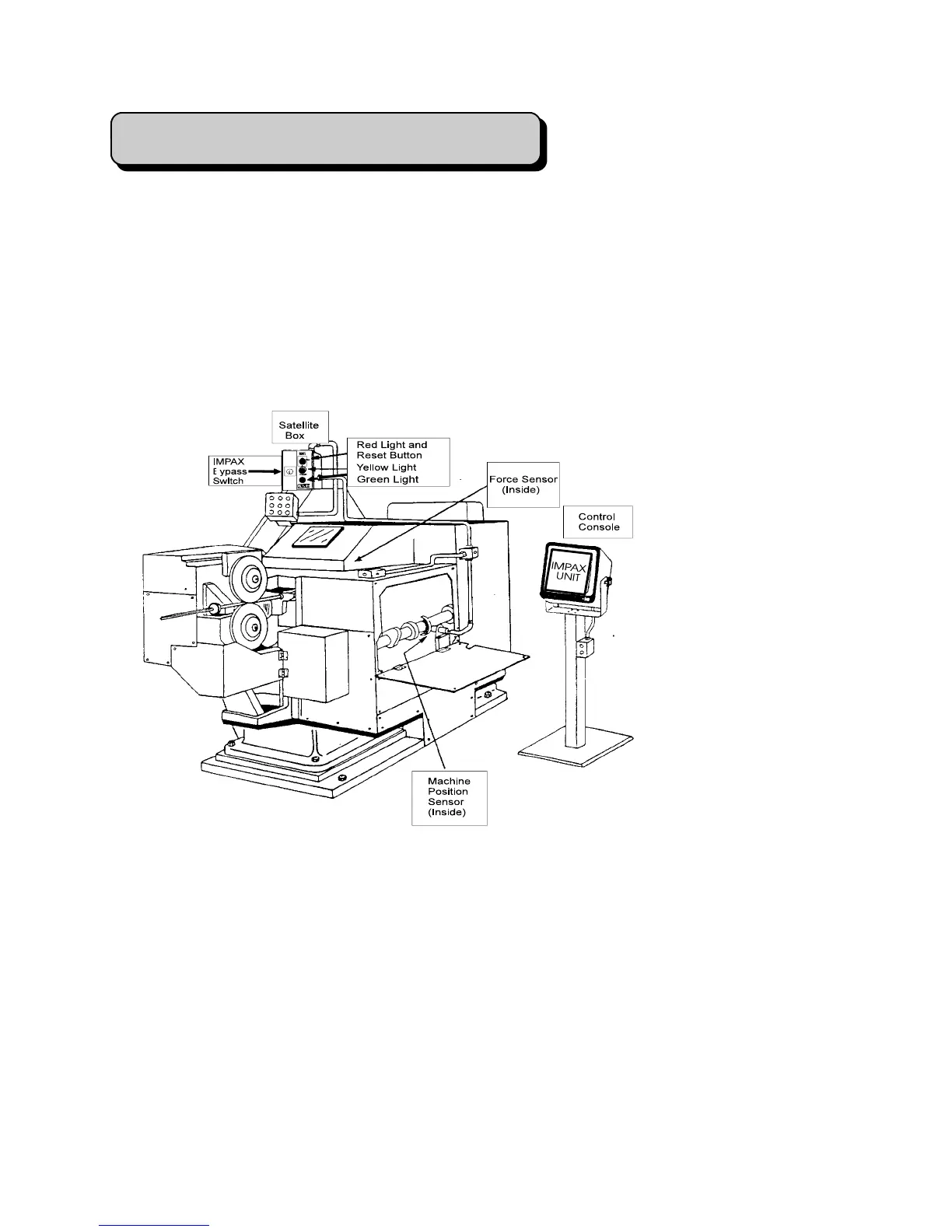

Chapter 2 - Description of Controls

The IMPAX monitor is comprised of several components which are interconnected by wiring.

All components are mounted on the forming machine except for the IMPAX Control Console

which is isolated on its own pedestal.

The Control Console is the core of the system, housing the microcomputer and power supply.

Its front panel contains the Message Display Panel and the Keypad, through which you can

receive information and enter commands. It also contains the Locking Keyswitch which

accepts the Supervisor’s Key. This key allows the supervisor or operator to ‘program’ IMPAX.

The Satellite Box is the

junction for all the

controls and

components on the

machine. The Reset

Button is the only

operator control. The

red, yellow, and green

Status Lights indicate

the mode of operation

that the IMPAX unit is

in. The Bypass Key

Switch, operated by the

Supervisor’s Key,

disables the relay which

stops the machine and

its accessories, but has

no other effect on

operation. Note: There

is no machine

protection when the

IMPAX monitor is in Bypass mode.

Up to two Machine Position Sensors are used to sense the machine cycle and synchronize the

stop signal. Piezoelectric Sensors are installed in stressed locations near the forming stations;

on the back of the die-bolster or backing plate, on knockout rockers, in punch wedges, etc. A

recess is cut (about the size of a quarter), or a hole is drilled, and the sensor is installed using a

special epoxy adhesive. When the machine is reassembled, the sensors are out of sight, but

sensitive to the forming process.

Relays within the Satellite Box are also wired to the Machine Stop Circuit (if available), as

well as to the feed stop and other accessories, as required to stop the machine and the process.

The Control Console interfaces with the Satellite Box via a multi-conductor cable.

Loading...

Loading...