14

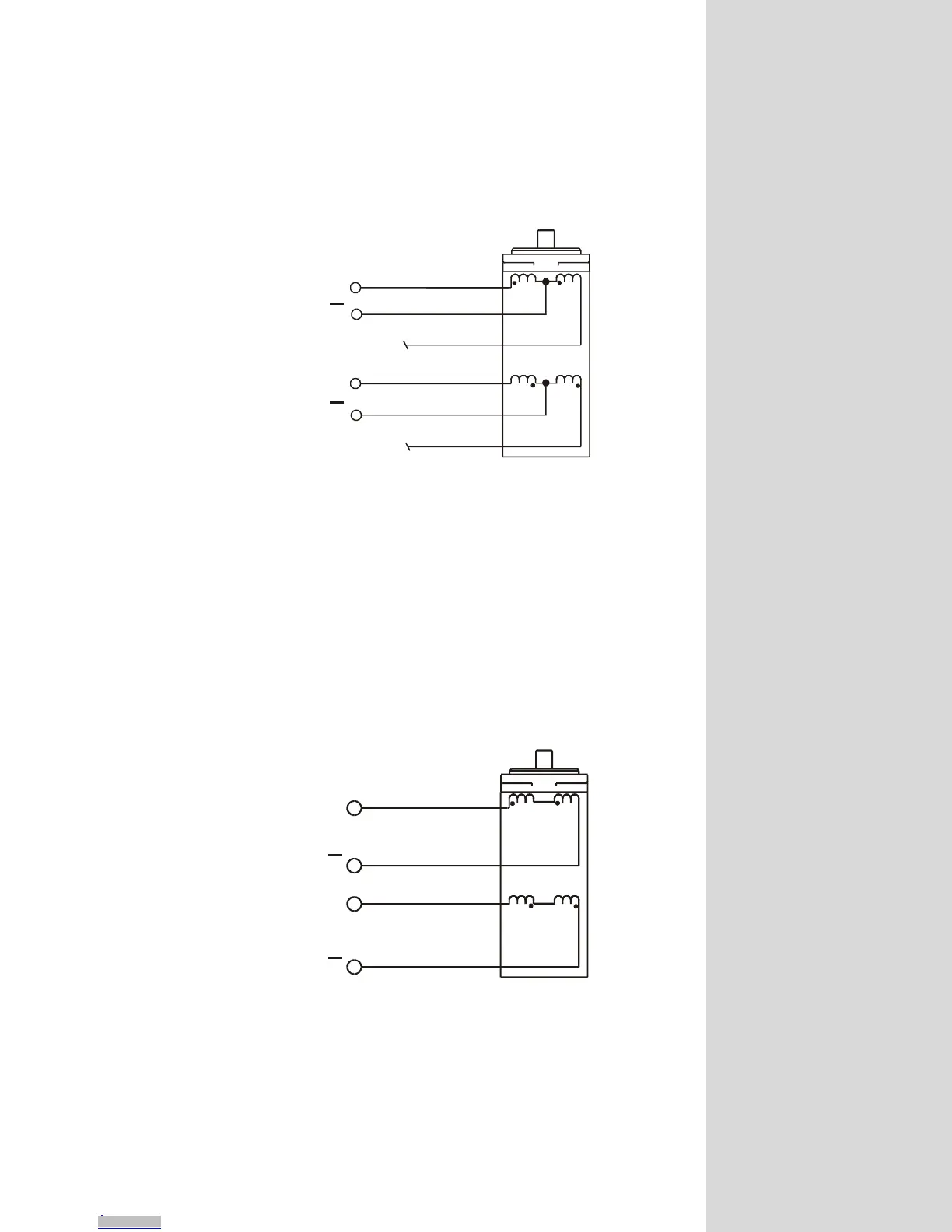

4 Lead Motor

4 lead motors are the least flexible but easiest to wire. Speed and torque will

depend on winding inductance. In setting the driver output current, multiply the

specified phase current by 1.4 to determine the peak output current.

PHASE A

NO CONNECTION

NO CONNECTION

PHASE A

PHASE B

PHASE B

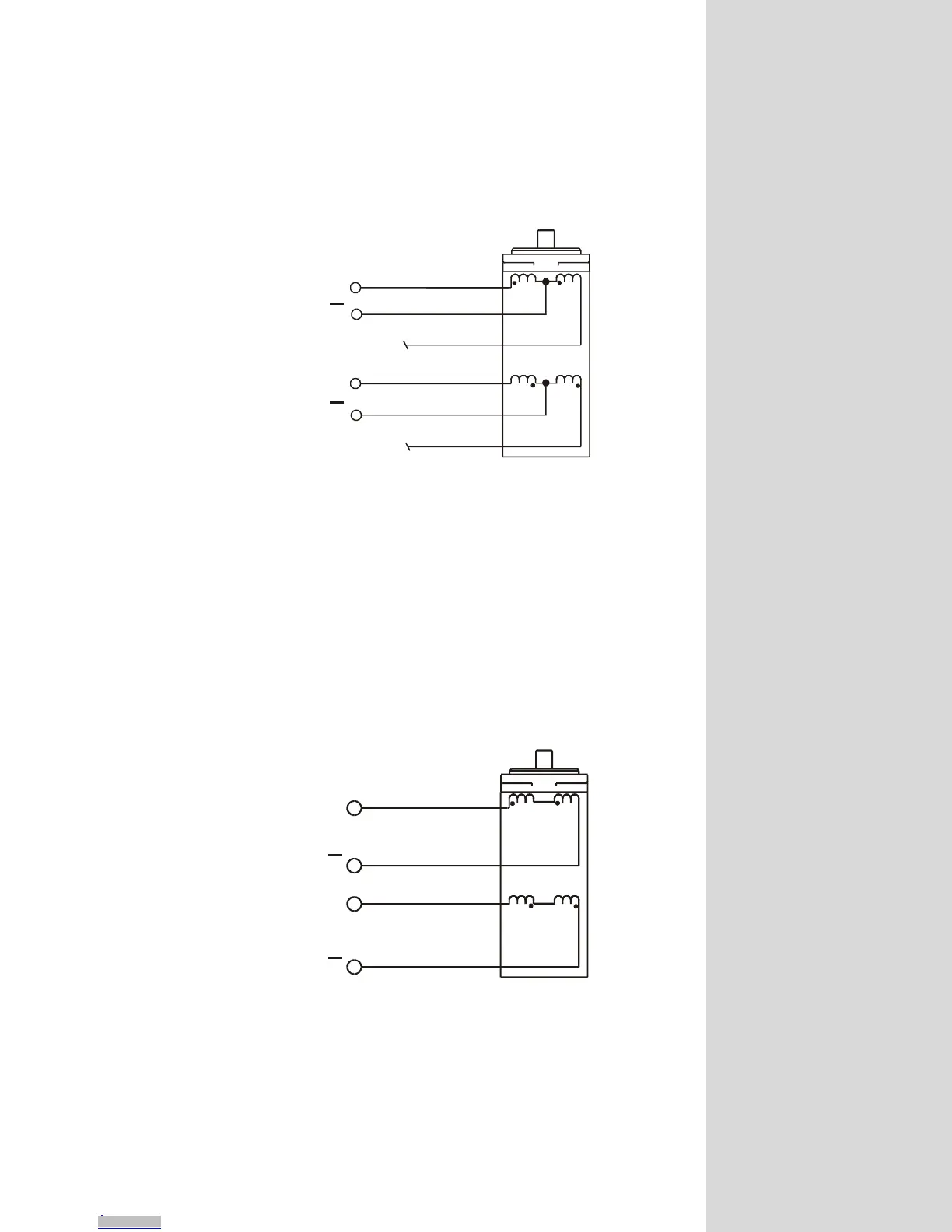

Figure 3.4: 6 Lead Motor, Half Coil Connection

Half Coil Configuration

As previously stated, the half coil configuration uses 50% of the motor

phase windings. This gives lower inductance, hence, lower torque output

at low speeds. As with the parallel connection of 8 lead motor, the

torque output will be increased at higher speeds. This configuration is

also referred to as half copper. In setting the driver output current,

multiply the specified per phase (or unipolar) current rating by 1.4 to

determine the peak output current.

PHASE A

PHASE A

PHASE B

PHASE B

Figure 3.5: 4 Lead Motor Connections

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Loading...

Loading...