VGC

TM

SEQUENTIAL VALVE GATE CONTROL

INSTRUCTION MANUAL

©INCOE® CORPORATION 2/2009

Pg.

www.incoe.com

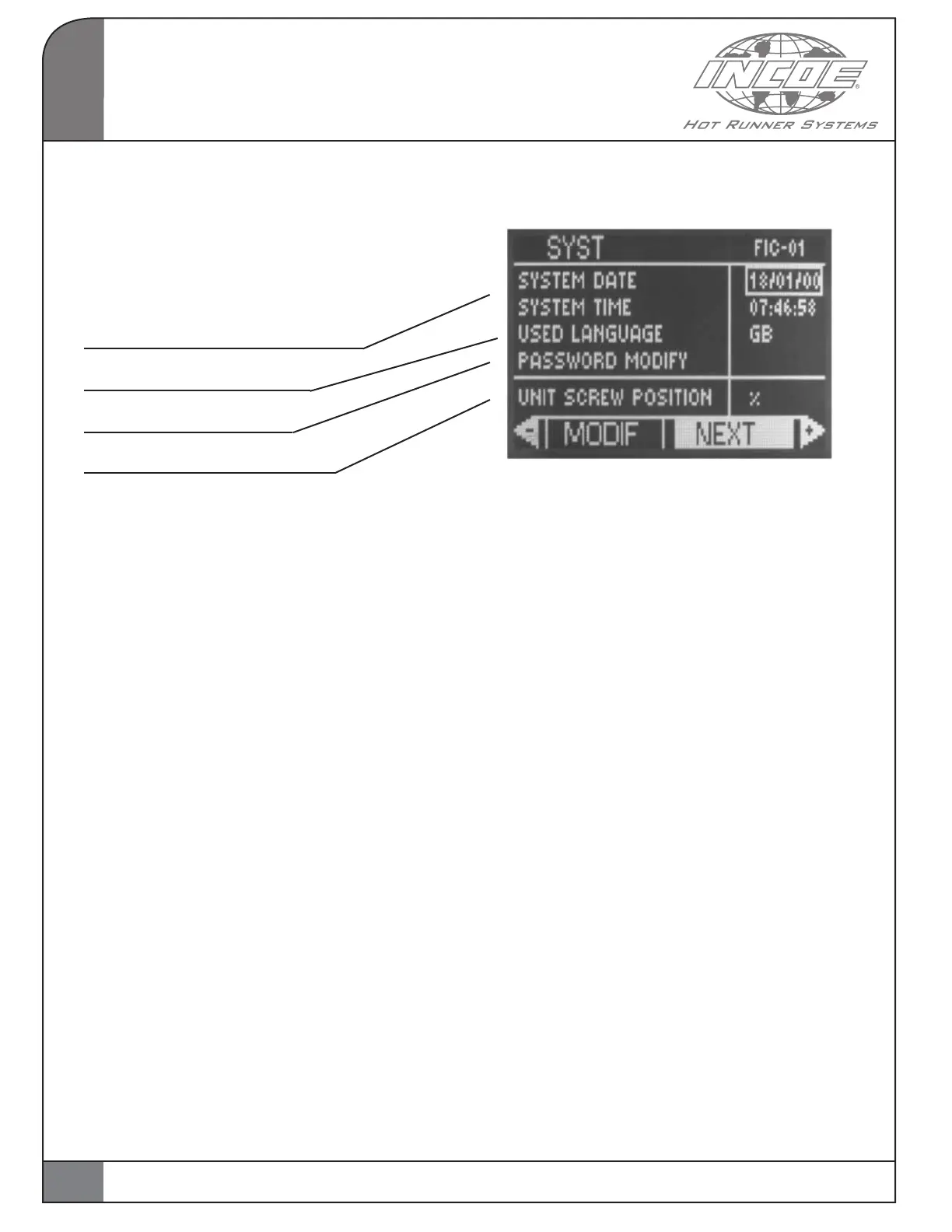

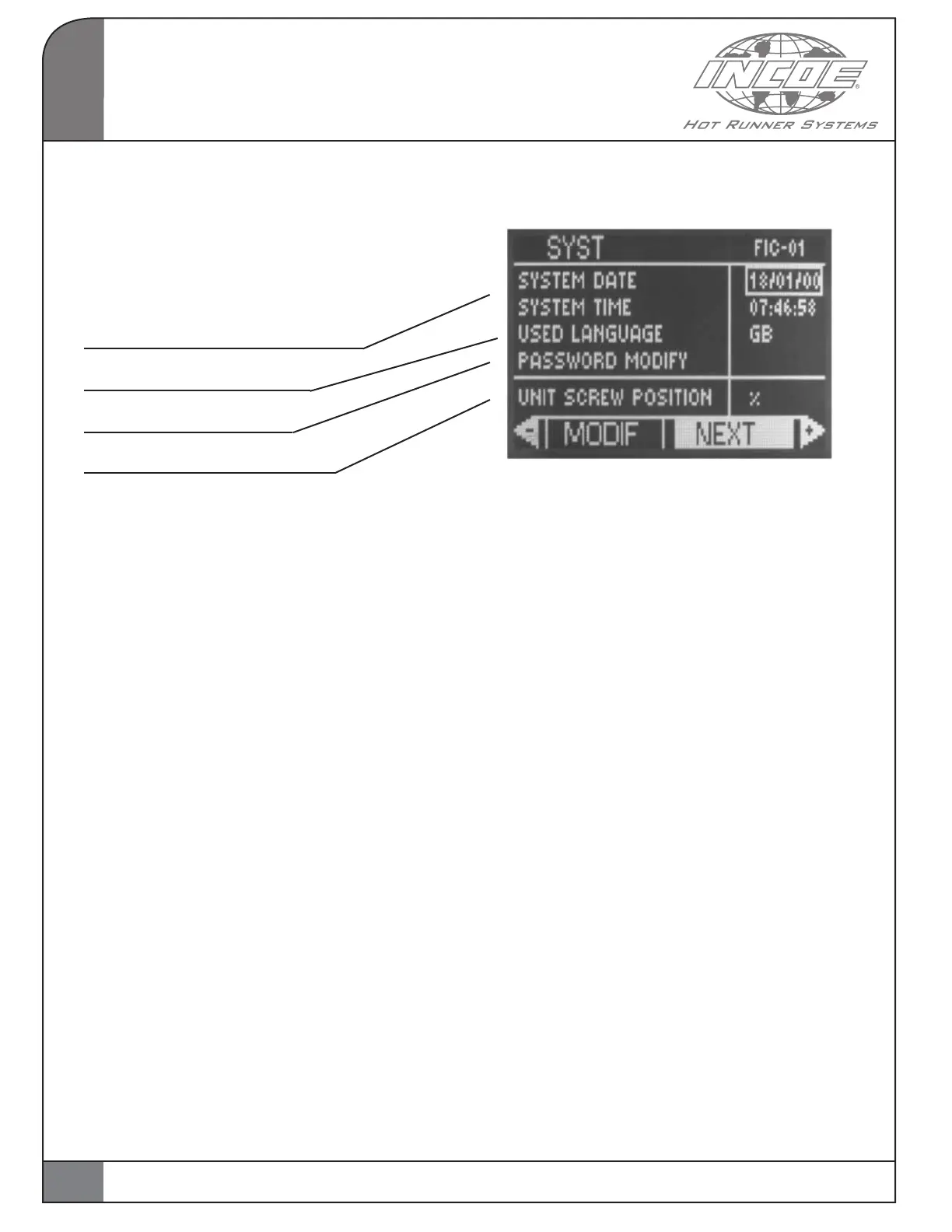

Press NEXT for accessing further system parameters

to select the unit for screw position, date, time,

language, etc….

Display and set system date and time

Select language

Modify keyboard password

Selection of Unit for Screw travel

OPERATION

2

10

Select MODIF to modify one of these 5 parameters

and validate. Possible choices are displayed above

the arrows as far as the language and the unit for

screw position. Enter the required value with the

keyboard for time, date and password.

1. Unit in (%):

This unit is related to the injected volume of

material. 0% is set at injection start and 100%

is reached when the screw is empty. This unit is

directly linked to the injection shot size of the

machine. If a sequence programmed on a machine

with an injection unit A is loaded on the controller

used on a machine with a different injection unit

B, the new shot size must be set so that the values

programmed in % remain valid.

2. Unit in (mm):

Values programmed using this unit depend on

the screw position not on the volume of injected

material. This unit does not rely on the shot size

but on the calibration of the screw position

signal received by the controller. A programmed

sequence using this unit relates to the machine

and any file using this unit should be modified to

be used on a different machine.

3. Unit in (cm3):

This unit depends on the calibration of the screw

position and on the injected volume of material. It

is independent from the shot size. A programmed

sequence using this unit can be used on a

different machine if the controller has been re-

calibrated for the new machine.

Advantages and disadvantages are on the

compatibility of saved sequence files loaded on

different injection units:

• Programs in % Re-calibration is not

required.

• Programs in mm: Re-calibration is required.

New calculation of

command values.

• Programs in cm

3

Re-calibration is required.

CAUTION: The programmed sequence is lost if the

unit for screw position is changed.

CAUTION: Check the programmed sequence after

changing the unit.

2.2.4 SELECTION OF UNIT MEASURE FOR SCREW TRAVEL

2.2.3 PROLONGING OF INJECTION SIGNAL (CONT’D)

Loading...

Loading...