VGC

TM

SEQUENTIAL VALVE GATE CONTROL

INSTRUCTION MANUAL

©INCOE® CORPORATION 2/2009

Pg.

www.incoe.com

1

5

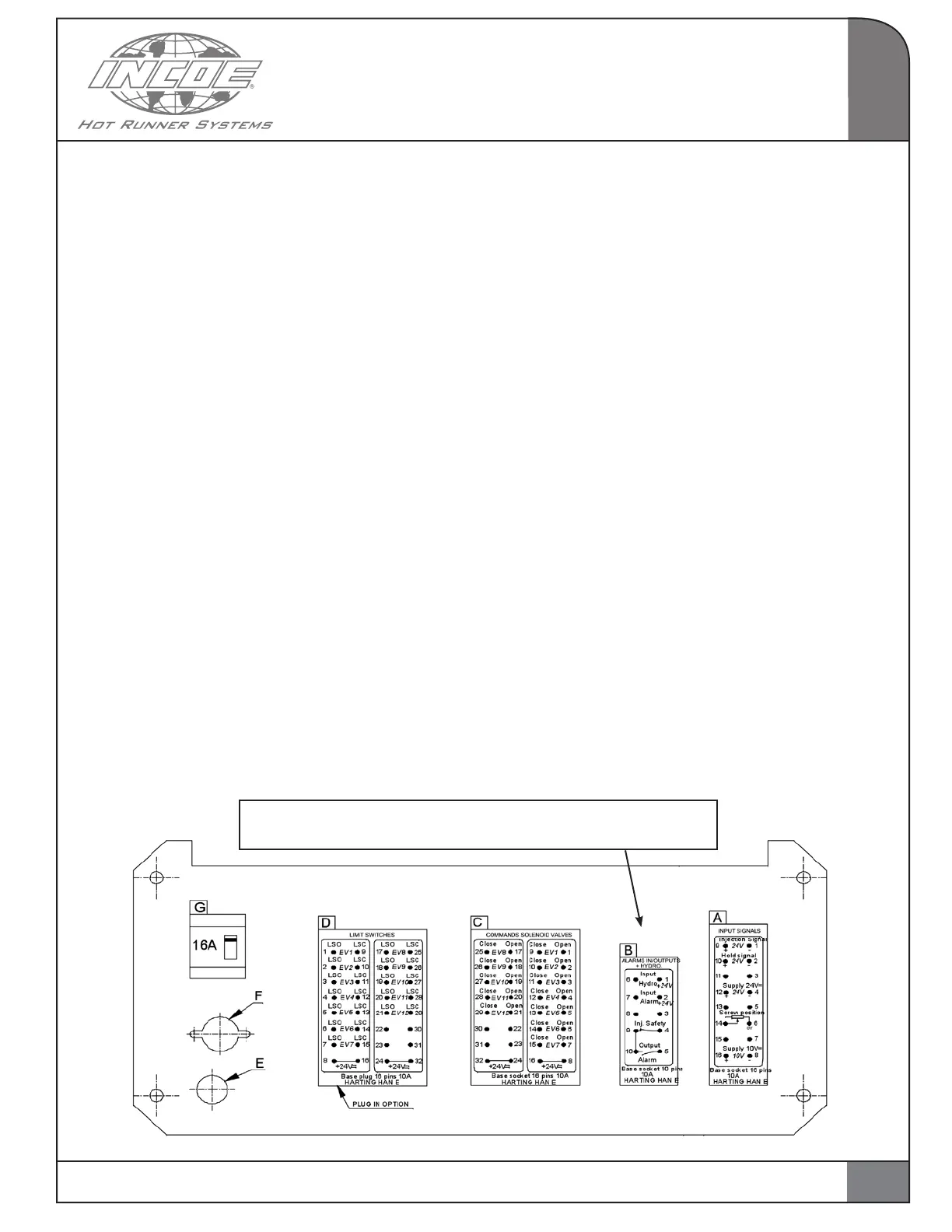

1.6 CONNECTIONS FOR VGC SEQUENTIAL

VALVE GATE CONTROL CABINET

A: Connector for input signals (16 pins 10A female).

B: Connector for alarm inputs and outputs, as well

as for security on hydraulic power pack (10 pins

10A female).

C: Connector for commands to valve gates,

voltage 24V DC, 1.5 Amps per valve gate

(32 pins 10A female).

D: Option : Connector for limit switches on valve

gates (32 pins 10A male).

E: Power supply cable inlet 3G2,5mm2 (Supply

voltage 230V AC 50/60Hz).

F: Fuse holder with fuse 16A on cabinet.

G: Circuit breaker 16A (switching cabinet on / off).

IMPORTANT NOTICE:

When connecting the signals from the press to

connector A on cabinet, it is recommended to split

0-10V signals and 0-24V signals. Use a cable with

shielded pairs, connect screw position with the

first pair and hold signal, injection signal and 0-24V

supply with the other pairs.

1.7 DIMENSIONS IN. (MM)

• Cabinet VGC Seq Valve Gate Control for 12

valve gates :

17” (431mm) L x H 8.5” (216mm) H x 18.5”

(470mm) D

1.8 FUSES AND CIRCUIT BREAKERS

• Fuse 16A type gI for cabinet (size 10x38 mm).

• Circuit breaker 16A.

• Fuses 6.3A on each control card (size 5x20 mm).

1.9 APPLICABLE STANDARDS

Cabinet VGC Sequential Valve Gate Control is

approved for the Specification CE 73/23 “Low

voltage” and fullfill the EN 61010-1 standards.

They also comply with the following standards:

Electrical noise industriel environnent : EN 50081-2

Electrical Noise Immunity in industrial

environment: EN50082-2

INTRODUCTION

There MUST be a plug on connector B. Use either a dummy plug,

or a plug that is using the features intended for Connector B.

Loading...

Loading...